Centrifugal Fan Types: A Selection Guide to Keep the Air Moving

By Grainger Editorial Staff 12/10/18

Centrifugal blowers, or fans, are among the most efficient and versatile pieces of air moving equipment. The scroll housing in a centrifugal fan accelerates the air and changes the direction of the airflow twice, a full 90 degree, before leaving the housing. Centrifugal blowers are quiet and reliable and are made to operate in a variety of environments and applications. Here are some basic definitions and guidelines to consider for selecting the right centrifugal blower for your system's needs.

Centrifugal Fan Blade Types

Centrifugal fans come in four basic fan types, each with its own specific purpose.

Radial: These are high-pressure fans with medium airflow. Radial-bladed fans are best for industrial applications where there is dust, or in environments where there is gas or moisture in the air.

Forward Curve: These are medium pressure, high airflow fans that can be used in both clean air, ventilating and exhaust applications.

Backward Curve: These are high-pressure, high flow, high efficiency fans. Power reduces as flow increases over the most efficient area of the system.

Airfoil: These are the highest efficiency fans, best in clean air applications.

Velocity Requirements

To choose the appropriate blower, you'll need to know how much pressure is required to reach the desired airflow to move air through the ducting and any filters, dampers or other obstructions in your ventilation system. If you have a lengthy, complicated duct system, you'll of course need a lot more power. Consider the impact of filters on the airflow too as this will also impact the pressure and power needed.

Direct Drive is more typical on smaller blowers and generally offers lower cost, fewer components to assemble, greater efficiency (no drive losses), reduced maintenance (no separate bearings or belts) and greater reliability.

Belt Drive offers greater flexibility in matching airflow requirements when equipped with a variable pitch motor pulley and is typical of larger blowers. When equipped with a variable frequency drive (three-phase blowers), direct drive blowers can offer the flexibility of belt drive blowers.

Environment

The environment in which the system operates must also be considered to choose the right blower-motor combination.

Outdoors: Consider a Totally Enclosed Fan Cooled (TEFC) electric motor on direct drive units, or a belt drive unit with an included weather cover.

Dirty or Dusty Environment: A TEFC motor is best for longer life and optimal efficiency.

Corrosive Environment: In wet, humid environments, a stainless steel blower is recommended, preferably with a stainless wash-duty motor.

Hazardous Environment: Consider a non-sparking blower, such as a radial or high-pressure blower, with an explosion-proof motor.

Air Quality

Clean Air: Consider a forward curve, backward incline or airfoil blower for increased efficiency.

Lightly Dusty Air: Consider a radial or high-pressure blower. For very light, non-abrasive dusts, a backward inclined blower is acceptable.

Heavier, More Abrasive Dust, Filings and Shavings: For this environment, you'll probably want an industrial material handing blower.

Corrosive: In wet, humid, corrosive environments, you should opt for a stainless steel blower, preferably with a stainless wash-duty motor.

Combustible: If there's combustible dust or particulate in the air, opt for a non-sparking blower, such as a radial or high-pressure blower with an explosion-proof motor.

Air Temperatures: Use belt drive units with steel wheels in higher temperatures. If temperatures climb above 250°F, consider an industrial blower with a heat slinger.

Designation for Rotation and Direction of Discharge

The direction of the rotation is determined from the drive side of the fan. On single inlet fans, the drive side is the side opposite the fan inlet. On double inlet fans with drives on both sides, the drive side should be on the same side as the higher-powered drive unit.

Fan Discharge Rotation

Clockwise Up Blast CW 360

Clockwise Top Angular Up CW 45

Clockwise Top Horizontal CW 90

Clockwise Up Blast CW 360

Clockwise Down Blast CW 180

Clockwise Bottom Angular Down CW 225

Clockwise Bottom Horizontal CW 270

Clockwise Bottom Angular Up CW 315

Counterclockwise Up Blast CCW 360

Counterclockwise Top Angular Up CCW 45

Counterclockwise Top Horizontal CCW 90

Counterclockwise Top Angular Down CCW 135

Counterclockwise Down Blast CCW 180

Counterclockwise Bottom Angular Down CCW 225

Counterclockwise Bottom Horizontal CCW 270

Counterclockwise Bottom Angular Up CCW 315

Notes:

- Direction of rotation and angular reference is determined from the drive side as defined below:

- On single inlet fans: The drive side is that side opposite the fan inlet.

- On double inlet fans:

- With a single driver: That side with the drive is considered the drive side.

- With multiple drivers: That side with the higher total power is considered the drive side. If the total power on each side is equal, then the side that has the fixed (non-expansion) bearing is considered the drive side.

- Direction of discharge is determined in accordance with diagrams. Angle of discharge is referred to the top vertical axis of fan and designated in degrees as measured in the direction of fan rotation. Angle of discharge may be any intermediate angle as required.

- A fan inverted for ceiling suspension or rotated for side wall mounting will have its direction of rotation and angle of discharge determined when fan is located as if floor mounted.

- This standard is in harmony with ISO 13349. In ISO 13349, CCW fans are referred to as LG, i.e., Left or Gauche, while CW fans are referred to as RD, i.e, Right or Droit-handed rotation.

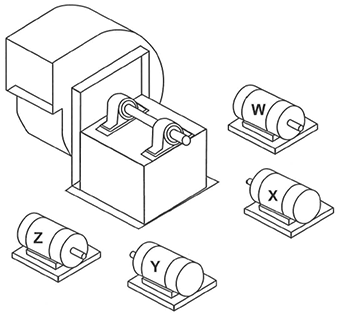

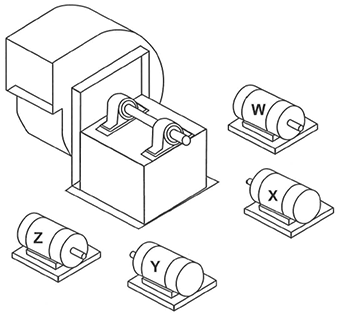

Drive arrangements for Centrifugal Fans AMCA Standard 99-2404-03

The drive arrangement names use these abbreviations:

- SW = Single Width

- DW = Double Width

- SI = Single Inlet

- DI = Double Inlet

Arrangements 1, 3, 7 and 8 are also available with bearings mounted on pedestals or base set independent of the fan housing.

Drive Arrangements for Centrifugal Fans AMCA Standard

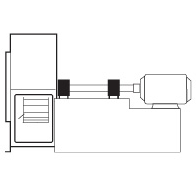

APR. 1 SWSI - For belt drive or direct connection. Impeller overhung. Two bearings on base.

ARR. 2 SWSI - For belt drive or direct connection. Impeller overhung. Bearings in bracket supported by fan housing.

ARR. 3 SWSI - For belt drive or direct connection. One bearing on each side and supported by fan housing.

ARR. 3 DWDI - For belt drive or direct connection. One bearing on each side and supported by fan housing.

ARR. 4 SWSI - For direct drive. Impeller overhung on prime mover base mounted or integrally directly connected.

ARR. 7 SWSI - For belt drive or direct connection. Arrangement 3 plus base for prime mover.

ARR. 7 DWDI - For belt drive or direct connection. Arrangement 3 plus base for prime mover.

APR. 8 SWSI - For belt drive or direct connection. Arrangement 1 plus extended base for prime mover.

APR. 9 SWSI - For belt drive. Impeller overhung, two bearings, with prime mover outside base.

ARR. 10 SWSI - For belt drive. Impeller overhung, two bearings, with prime mover inside base.

Motor Position

The location of the motor is determined by facing the drive side of the fan and designating the motor positions by the letters W, X, Y or Z as needed.

Facility maintenance pros like you have many jobs to do in the course of the day. So if HVAC isn't your primary field of expertise, we hope these basics provide some of the guidelines you need when it comes time to seek the advice from a trusted HVAC engineer. Choosing the right combination of blowers and motors for the intended workload and environment is critical in making your system the most efficient it can be while helping to keep energy costs down.

| psi | "WG | "Hg |

|---|---|---|

|

1 |

27.736 |

2.036 |

|

0.03605 |

1 |

0.07341 |

|

0.49116 |

13.623 |

1 |

|

0.000145 |

0.00403 |

0.000295 |

|

0.00142 |

0.03937 |

0.00289 |

|

0.01934 |

0.53632 |

0.03937 |

|

14.696 |

407.61 |

29.92 |

Pressure – Metric System

| N/m2* | mmWG | mmHg | atm |

|---|---|---|---|

|

6894.7 |

704.49 |

51.714 |

0.06805 |

|

248.36 |

25.4 |

1.8628 |

0.00245 |

|

3386.4 |

346.02 |

25.4 |

0.03342 |

|

1 |

0.10219 |

0.0075 |

0.0000098 |

|

|

1 |

0.07341 |

0.00009661 |

|

|

|

|

|

|

|

|

|

|

Symbol Definitions

| Symbol | Definition |

|---|---|

|

atm |

Atmospheres |

|

°C |

Degrees Celsius |

|

cfm |

Cubic feet per minute |

|

°F |

Degrees Fahrenheit |

|

fpm |

Feet per minute |

|

Hg |

Mercury |

|

hp |

Horsepower |

|

hr |

Hours |

|

kW |

Kilowatts |

|

m |

Meters |

|

mm |

Millimeters |

|

min |

Minutes |

|

N |

Newtons |

|

psi |

Pounds per square inch |

|

sec |

Seconds |

|

W |

Watts |

|

WG |

Water gauge |

The information contained in this article is intended for general information purposes only and is based on information available as of the initial date of publication. No representation is made that the information or references are complete or remain current. This article is not a substitute for review of current applicable government regulations, industry standards, or other standards specific to your business and/or activities and should not be construed as legal advice or opinion. Readers with specific questions should refer to the applicable standards or consult with an attorney.