A Preventive Maintenance Checklist

By Grainger Editorial Staff 5/10/24

What is preventive maintenance? Any maintenance activity, such as an inspection, servicing or replacement, that's performed as part of a scheduled plan, rather than as a response to a breakdown, can be considered preventive maintenance.

And what is the purpose of preventive maintenance? By identifying components or parts that are wearing out and repairing or replacing them before they fail, an effective preventive maintenance program can help limit production downtime and extend the service life of equipment and facilities.

In these theoretical terms, preventive maintenance is a simple idea. But like many simple ideas, it can be challenging to make it a reality. In practice, a preventive maintenance program can be quite complex: there's a great deal of data to be collected and analyzed, and many competing tasks to schedule, prioritize and cost.

Any preventive maintenance program can be thought of as having four general components, according to "The Complete Guide to Preventive and Predictive Maintenance" (2003). For a program to be effective, each component has to be working well. "The Complete Guide" describes the components as follows:

Engineering: Does the maintenance schedule include the right tasks, at the right frequency, to identify and remedy critical wear?

Economic: Are the scheduled maintenance activities worth doing economically? When all the costs associated with equipment failure are factored in, such as downtime and safety considerations, does it cost less to keep maintaining the asset than to replace it?

People-Psychological: Are the employees who perform the preventive maintenance sufficiently motivated and trained to do this detail-oriented work correctly?

Management: Is preventive maintenance built into business processes and operations, and are operations systems designed to produce good preventive maintenance outcomes?

Any preventive maintenance program should be clearly defined, with well-documented maintenance activities for each piece of equipment. It should also be regularly reviewed and adjusted as necessary.

Assembling a program like this can be a challenge, but the basic building blocks of what "The Complete Guide" calls the engineering component—which is arguably the most critical part—are simple processes and schedules. Consider these preventive maintenance checklists as a starting point as you think about the maintenance activities that can help keep your facility functioning.

LIGHTING

- Inspect lighting on a regular schedule. Make sure your inspection list includes all the lighting in your facility:

- Check all exit lighting for proper installation and function

- Check all interior lighting for proper installation and function

- Check all exterior lighting for proper installation and function.

- Replace any nonfunctional lamps you encounter. When lamps begin to fail, consider relamping them as a group. You can create a schedule for relamping by estimating the average duration of lamp use in a week or a month and comparing that to the expected service life of the lamp.

- When replacing lamps, check that the color temperature to maintain consistency.

- Dust and clean dirty lamps, and check that they're aimed as intended.

- Consider any luminaires that have transformers or control gear.

- For exterior lighting, check that hardware and cabling is intact.

SAFETY

- Check inventory and restock all first aid kits.

- Check eyewash bottles and stations.

- Ensure safety signs and equipment labels are in good condition.

- Inspect and clean respirators.

- Inspect fall protection harnesses and kits.

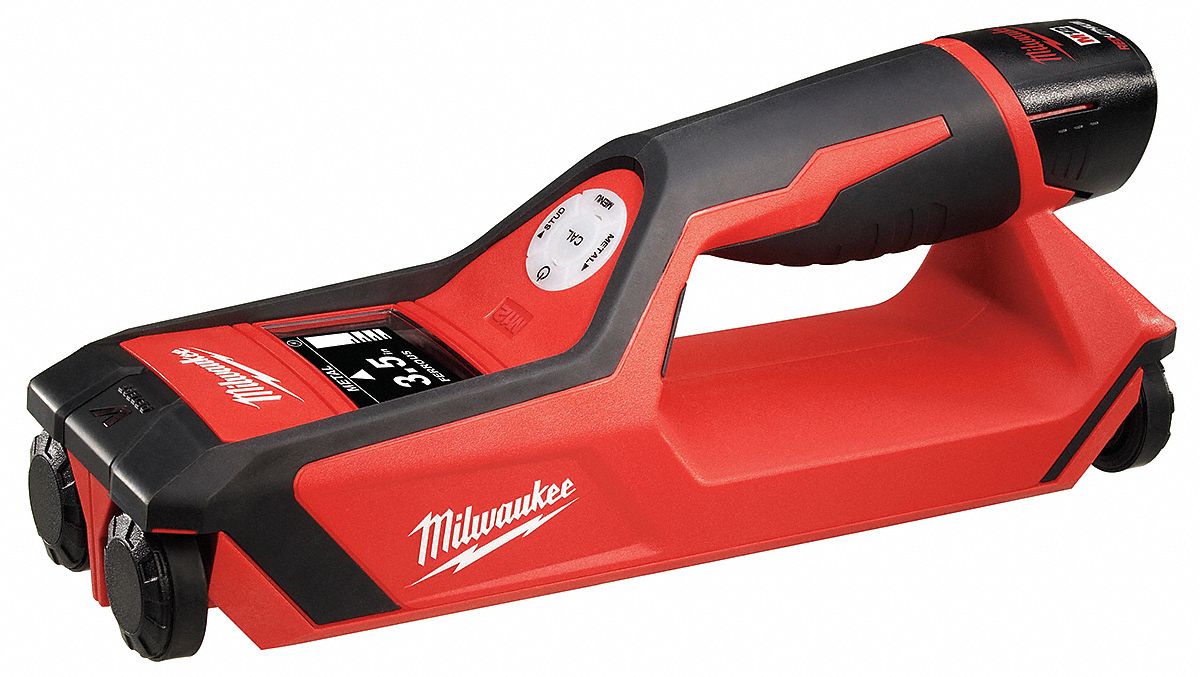

- Change batteries in smoke and carbon monoxide detectors, flashlights and test instruments.

HVAC/R and PNEUMATICS

- Clean the air intake if necessary.

- Change all blower motors in operation for excessive noise or vibration.

- Clean motors and ductwork if necessary.

- Check that the condensate drain pan is draining properly.

- Check the flexible duct connectors.

- Inspect and clean all exhaust fans.

- Secure loose guards and panels.

- Inspect all electrical connections and hardware.

- Test all safety controls.

- Check for proper operation of the interior unit.

- During the cooling season:

- Inspect the condenser motor bearings.

- Inspect the condenser coil, air intake and discharge.

- Check all refrigerant piping and insulation.

- Secure any loose guards or access panels.

- Check the operation of the exterior unit.

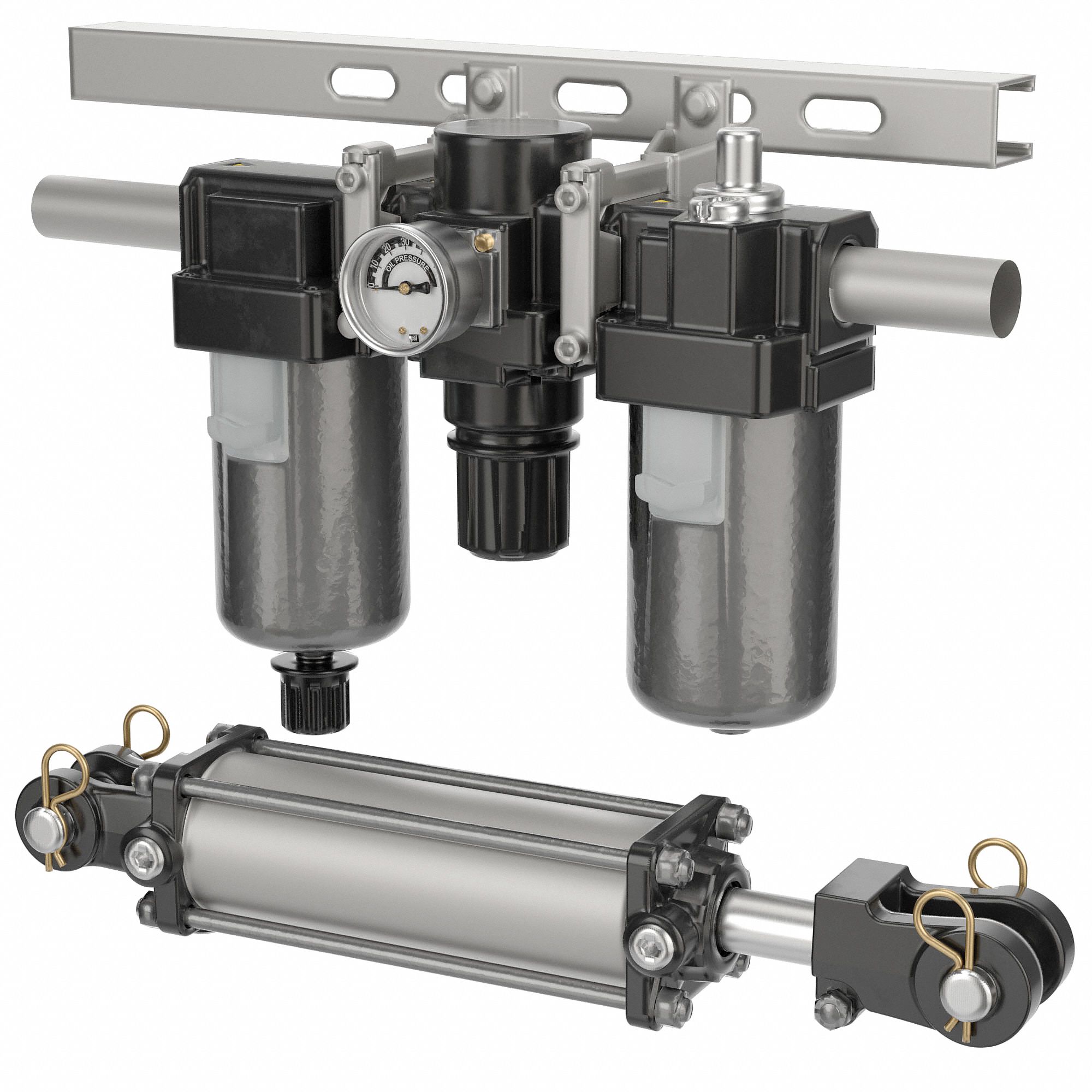

- Inspect compressed air lines regularly; investigate any leaks in piping, tubing or fittings.

- Replace or clean air filter elements at least quarterly, or as necessary depending on the application.

- Monitor oil levels on air compressor pumps and replace as necessary depending on usage.

PLUMBING

- Inspect plumbing according to a regular schedule, and investigate any leaks or unusual noises.

- Lubricate bearings in domestic water booster and circulation pump systems according to a regular schedule.

- Inspect couplings and check for any leaks.

- Fire-test domestic water heaters and boilers according to a regular schedule. Optimize efficiency using flue-gas analysis to adjust the flue draft and combustion air input.

- Lubricate condenser fan motor bearings on remote drinking water. Check contacts for wear, and run system control tests. Remove the refrigerant according to manufacturer instructions. Drain and replace oil in the compressor oil reservoir, including strainers, traps and filters.

- Check function of sump and sewage ejection pumps. Lubricate exposed pumps according to a regular schedule.

![]()

![]() Shop Preventive Maintenance Supplies

Shop Preventive Maintenance Supplies

BUILDING INTERIOR

- Examine the floors, ceilings and walls for evidence of deterioration.

- Check for evidence of leaks.

- Inspect for safety hazards, including electrical hazards, slipping and tripping hazards, and falling hazards.

- Check the condition and operation of toilets and showers.

- Test smoke and carbon monoxide detectors.

- Test the fire alarm system.

- Check fire extinguishers and any firefighting equipment.

- Check doors for proper operation and make sure that exits are not obstructed.

- Inspect door locks and closures.

- Ensure work areas and walkways are clearly and visibly marked.

- Check for garbage in storage areas.

- Check for evidence of insect or other pest infestation.

- Inspect cart casters for signs of wear.

- Make sure that shelving is secure, organized and labeled.

- Inspect electrical receptacle cover plates for tightness and damage.

- Confirm that controls such as timers and photocells are functioning.

BUILDING EXTERIOR

- Check the condition of the paint and walls.

- Check for plants on the building and its foundation.

- Look for broken windows, doors and railings.

- Inspect the roof, cleaning it if necessary. Use the appropriate fall protection or prevention measures when working in high places.

- Clean drains and gutters on the roof, testing downspouts and drains by flushing them with water.

- Make sure gutters are appropriately anchored.

- Inspect the stack and all roof penetrations.

- Remove any plant life growing on the roof.

- Clean up any broken glass or other debris.

- Examine the condition of the sidewalk, driveway and parking lot.

- Check the storm drains.

- Check trees to make sure that no branches are about to fall.

- Check that the area around the trash bins is clean.

- Examine the condition of any fencing.

Find more building maintenance and operations know how here.

PPE in the Workplace

Procure the Right PPE for Chemical Manufacturing

See why employees in chemical manufacturing facilities need to choose the right personal protective equipment (PPE) to help limit chemical exposure.

![]() OUR LATEST KNOWHOW

OUR LATEST KNOWHOW

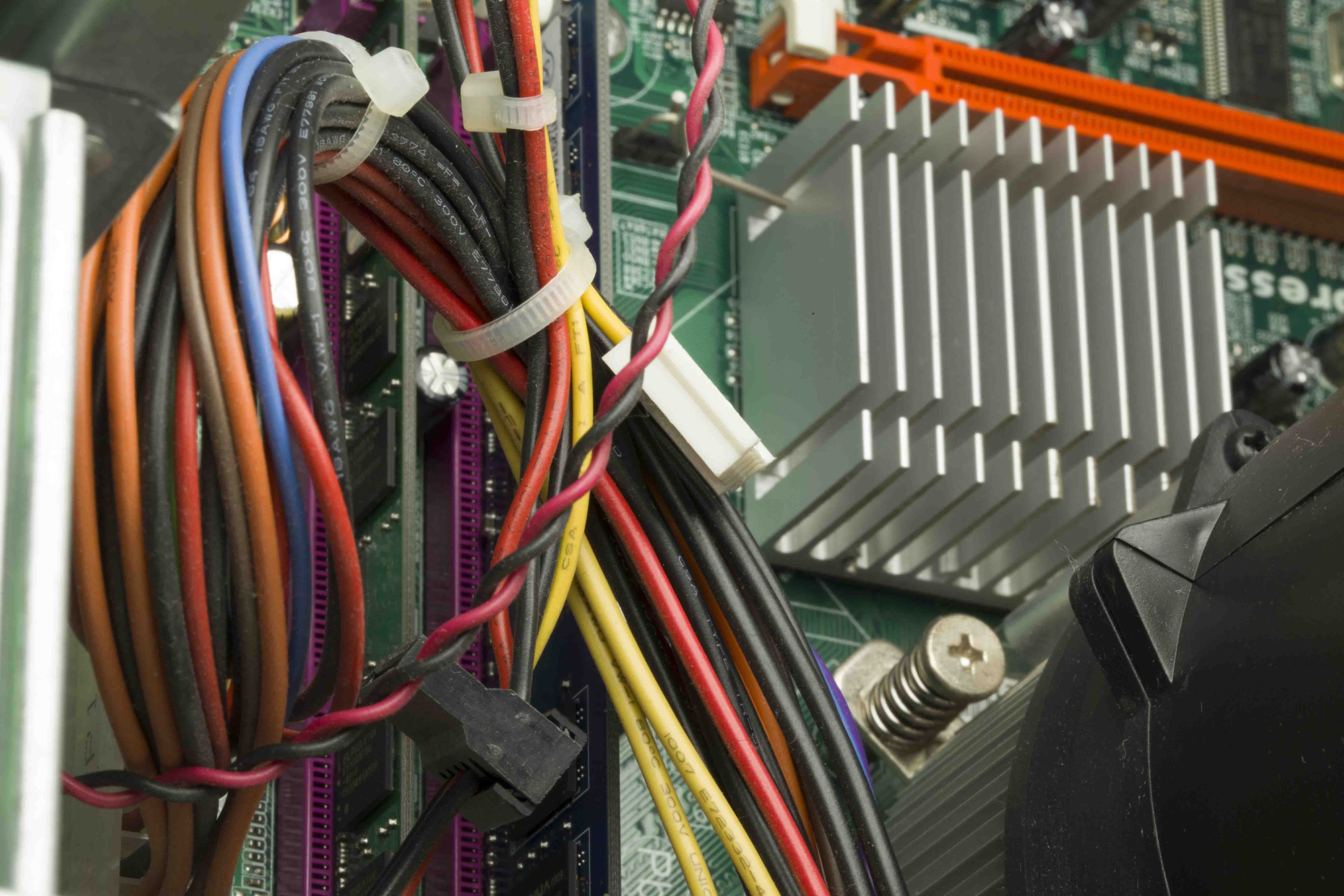

Equipment

9 Tips for Wire and Cord Management at Work

Wire Management can be a real hassle in the office and warehouse. Learn from these 9 wire management tips to get the wire mess under control.

The information contained in this article is intended for general information purposes only and is based on information available as of the initial date of publication. No representation is made that the information or references are complete or remain current. This article is not a substitute for review of current applicable government regulations, industry standards, or other standards specific to your business and/or activities and should not be construed as legal advice or opinion. Readers with specific questions should refer to the applicable standards or consult with an attorney.