Inventory Management

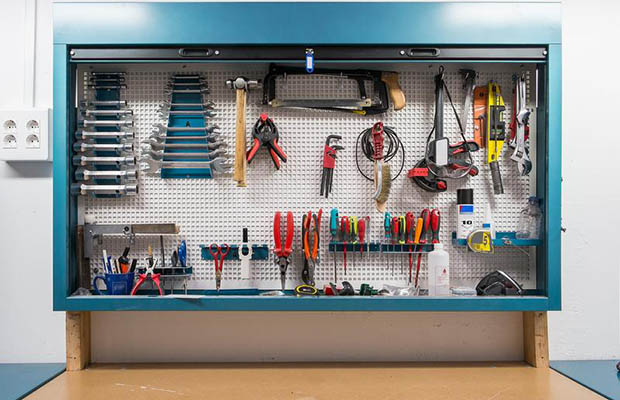

Creative Ways to Make the Most of a Small Workspace

These guidelines that can help you make the most of a painfully small work area.

12/21/23

Inventory Management

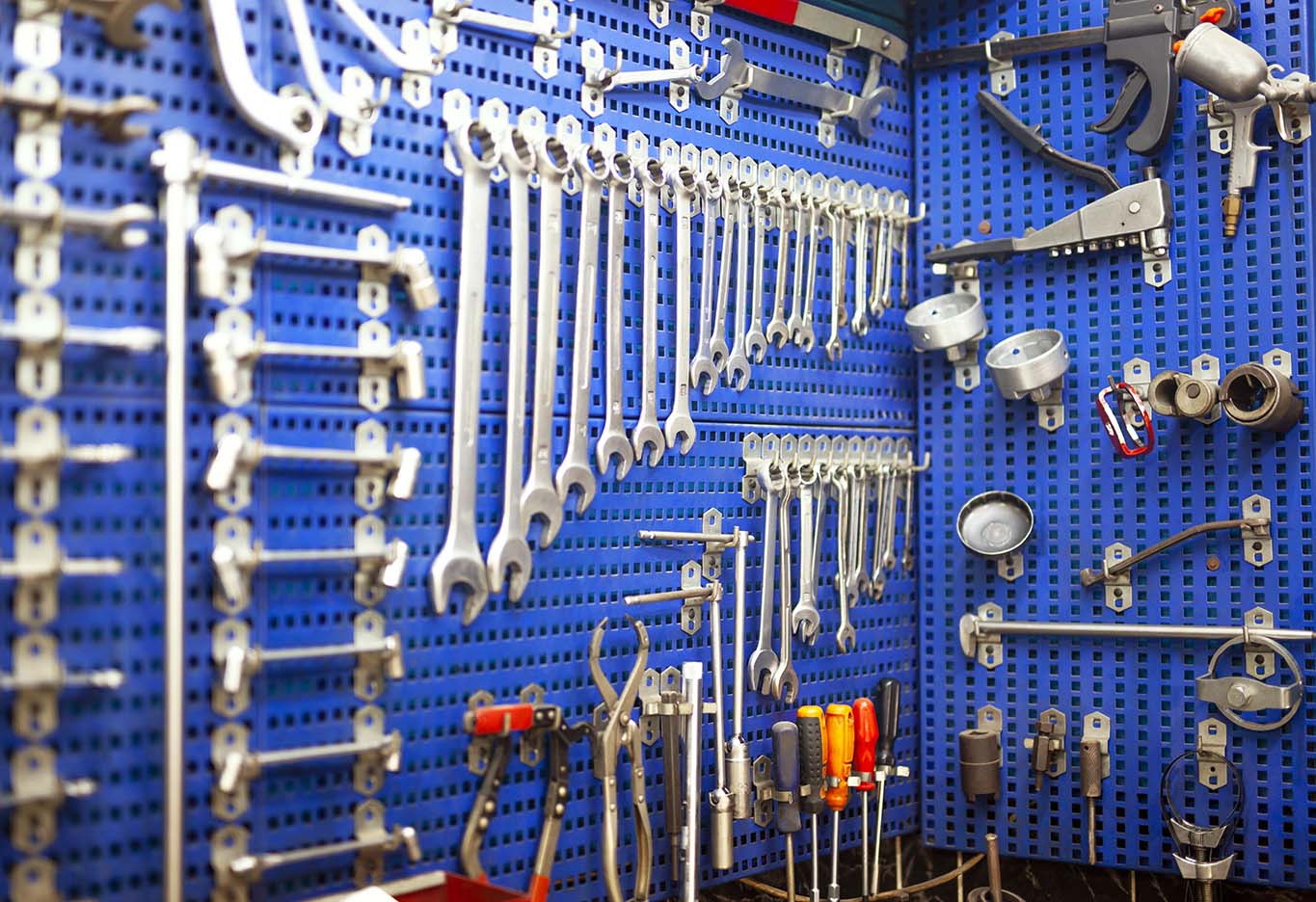

5 Benefits of Using the 5S System for Managing Tools and Equipment

Learn how the 5S System works and how your business could benefit from implementing the system.

09/14/23

Inventory Management

Supply Chain and Inventory Management Trends 2022-2023: A Grainger Report

This page shares highlights from a 2022 survey of Grainger customers on how they are managing inventory in today's supply chain climate, and gives users the opportunity to download a full report on the survey findings.

05/25/23

Inventory Management

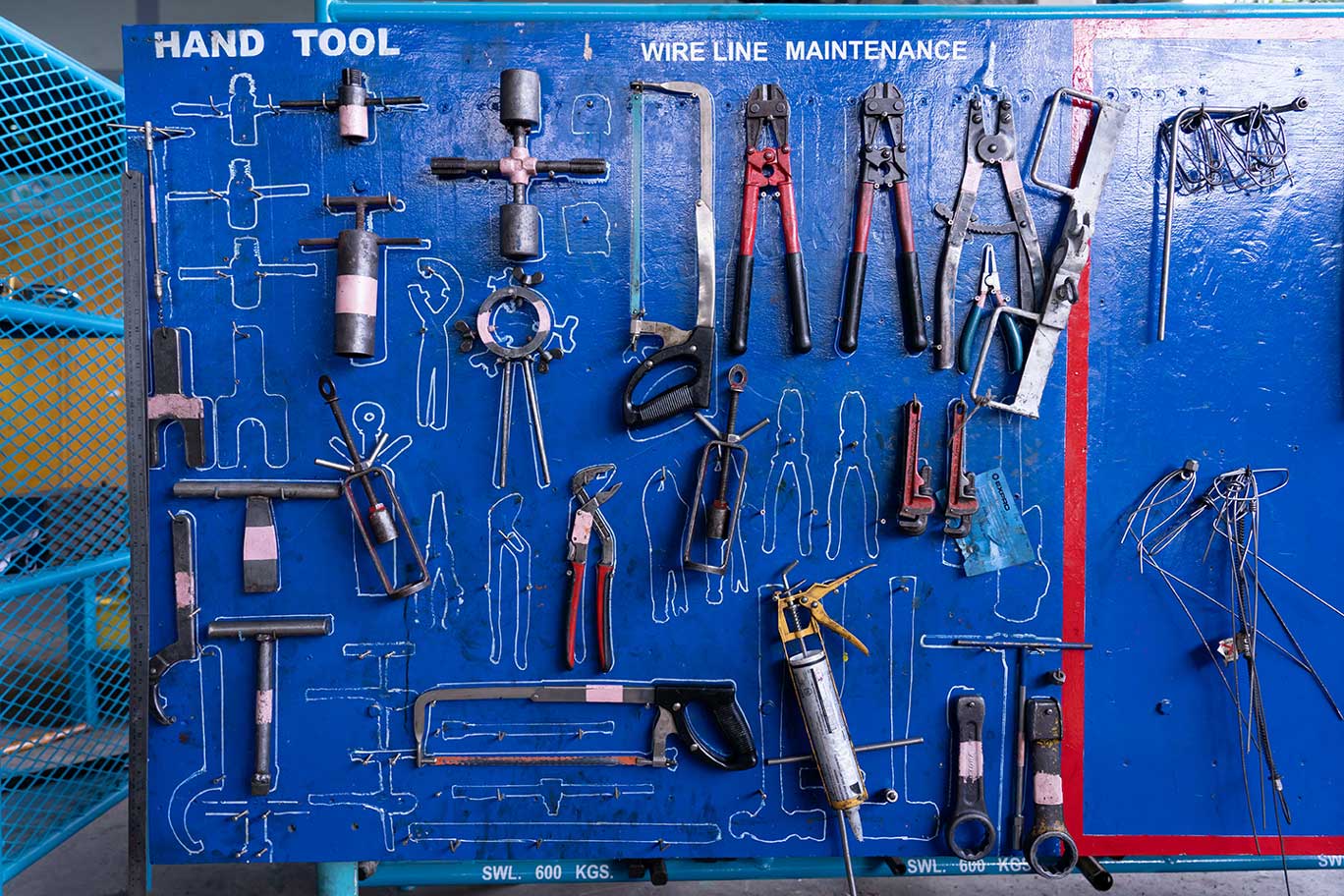

Solutions for Tracking Misplaced or Stolen Tools

Learn simple and effective ways to help track and protect your tools and equipment from being lost or stolen.

05/23/23