The List of Power Tools Every Business Should Have

By Grainger Editorial Staff 5/25/21

Nearly every business in every industry needs to do minor repairs or maintenance projects from time to time. These tasks may be too small to call in the professionals, but important enough that they shouldn't be overlooked.

Even if you work from home, on the road or in a facility, it can be helpful to have basic tools for quickly completing small repairs. Power tools—typically powered by electricity or battery packs—may be the best option for these small jobs. Here's an essential list of power tools to add to your toolbox.

- Cordless Drill

Drills make holes or turn fasteners. They come with interchangeable bits that make different-sized holes or turn different fastener types. Cordless drills run on batteries, making the drill portable, but the batteries must be recharged when battery power runs low. Corded, air-powered and gas-powered drills are an option, but a cordless pistol grip drill offers a versatile choice for a basic toolbox. As the name suggests, these drills are gripped like a pistol and a trigger switch activates operation. When choosing a drill, consider its weight, battery run-time and bit options.

- Circular Saw

A circular saw is handheld and uses a rotating blade to cut a variety of materials. There are corded and cordless circular saws. Corded saws require electricity to operate, but may offer more power and can run longer than cordless versions. Cordless saws are also more portable and can be general-purpose or metal-cutting specific. General-purpose saws are used to cut wood and potentially other materials such as plastic. Metal-cutting saws tend to be used for autobody work and metal fabrication. You can choose a right-side or left-side blade. You may also choose the cutting depth of the blade and the bevel cutting angle range.

- Angle Grinder

Angle grinders have rotating blade heads set at a right angle to the tool body. They have a wide range of uses: grinding metal and welds, preparing concrete surfaces, cutting pipe or metal, polishing stone, concrete or metal, routing out mortar, removing rust or paint, sharpening other blades and sanding or polishing surfaces. There are corded and cordless angle grinders, as well as air-powered grinders which are often used in manufacturing settings where air compressor systems are readily available. Corded types offer high power and can run longer than cordless. Cordless types offer portability. You can choose a standard head or a flat head. Flat heads tend to work better in tight spaces. Other options to consider are the grip type. A more ergonomic grip may be helpful if the tool will be used more frequently or for long periods.

- Cordless Oscillating Multi-Tool

Cordless oscillating multi-tools are hand tools with blades or attachments that move in a small arc from side to side at high speeds. Accessories, such as blades, hooks and pads, allow the tool to perform different functions like cutting, polishing, scraping, sanding and grout or sealant removal. Choose a tool based on the accessories you need, battery life and blade oscillation angle. The greater the angle, the more aggressive the action.

- Reciprocating Saw

Reciprocating saws make aggressive cuts with a blade that uses quick back-and-forth motion. These saws are best used when precision and finished edges are not required. They are often used for construction, demolition and metalworking. They cut wood, metal, nail-embedded wood and mixed-composition materials. These saws come as corded, cordless and air-powered. Cordless versions are popular for their portability and ease of movement around a worksite. Compact sizes allow for one-handed operation and full-size require two-handed operation.

- Rotary Tool

Rotary tools are similar to oscillating tools in that they are hand-held and multi-functional. They have a body to which you attach various attachments for specific uses. The small size of these tools allows them to be used for detail and finish tasks such as repairing, restoring and crafting because they can get into tight spaces and crevices. They may be used for cutting, engraving, routing, grinding, sanding and polishing. There are corded and cordless options, as well as a host of bits and attachments that adapt the tools for specific uses.

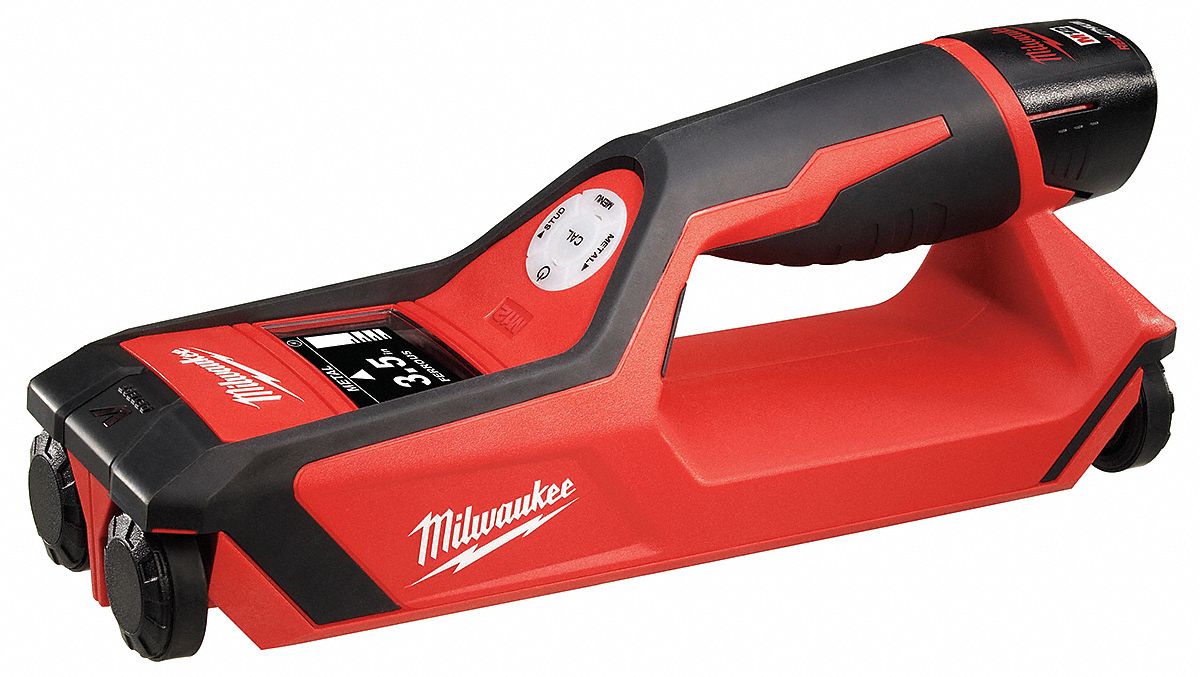

- Impact Driver

Impact drivers operate similarly to drills in that they tighten and loosen fasteners, such as screws and bolts, and can also use impact to create holes. They are known as impact tools because, when they encounter resistance, they use an impact mechanism to increase torque. Depending on your needs, these tools can be a substitute for a drill and are often smaller and lighter. You can choose cordless or manual versions. Choose a tool based on maximum torque, RPMs and grip, which can be either a pistol grip or a right-angle grip used to reach into tight spaces.

- Impact Wrench

Like impact drivers, impact wrenches use impact mechanisms that increase torque when resistance is encountered. These tools drive and remove fasteners, primarily in construction, maintenance, assembly and automotive applications. Air-powered impact wrenches are lighter than electric-powered and work well in settings where workers need to handle the tools for extended periods. These tools also come in corded, cordless and hydraulic options. An impact wrench delivers power in bursts to minimize operator stress from handling the tool. Drive size, as well as fastening and breakaway torque, are the main considerations when choosing a tool. The larger the drive size, the more torque you typically have. It’s important to note that breakaway torque will always be equal to or greater than the fastening torque so that you can always remove the nut after it has been fastened.

If you’re looking to complete different tasks than the ones listed above, you can consider these additional power tools and specialized tools. If you need to complete less complex tasks, consider adding these hand tools to your list of essentials.

![]()

The information contained in this article is intended for general information purposes only and is based on information available as of the initial date of publication. No representation is made that the information or references are complete or remain current. This article is not a substitute for review of current applicable government regulations, industry standards, or other standards specific to your business and/or activities and should not be construed as legal advice or opinion. Readers with specific questions should refer to the applicable standards or consult with an attorney.