How to Choose Label Printer Supplies for Your Workplace

By Grainger Editorial Staff 8/27/25

Workplace labeling is key to safety, compliance and efficiency. This guide breaks down how to choose the right label printer, labels and ribbons based on your environment, application and durability needs—so your facility stays organized and OSHA-compliant.

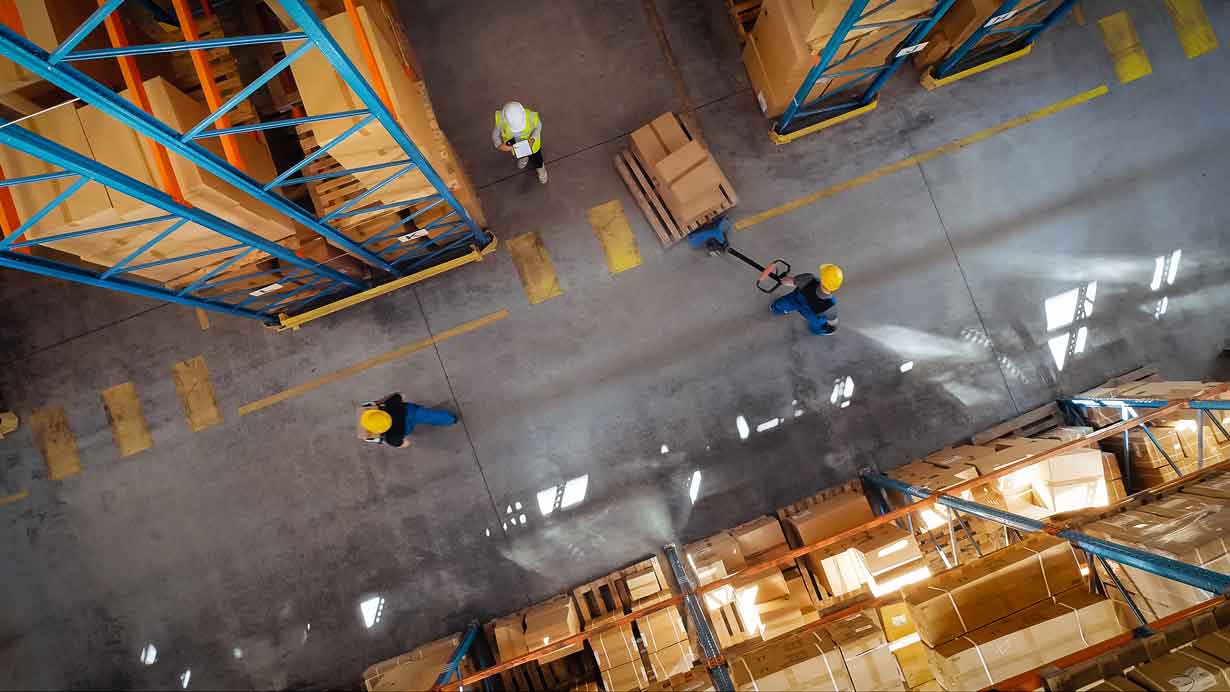

Workplace labeling plays a critical role in ensuring a facility stays safe, compliant and well-organized. From floor marking tape that helps direct traffic, to laboratory labels designed to resist chemicals and tamper-evident labels that show when equipment may have been compromised, the right labeling system can help support both safety and efficiency. OSHA’s Hazard Communication Standard, which covers chemical hazard notifications, was the second most commonly-cited standard in 2024, underscoring the need for clear and reliable labeling solutions.

While pre-printed signs can handle some notification situations around a facility, many others are best served by printing customized labels and tags on site. This will require a specialized printer and compatible ribbons and labels. Here are some key considerations to keep in mind when trying to decide what is best for your needs:

- Do you need labels for specific applications, or will general-purpose labels do the job?

- What types of conditions do the labels need to withstand, like heat, moisture or chemicals?

- How big is the largest label you'll need to print?

- Will you be printing on the go, or mostly from a workstation?

Tips for Selecting a Printer

Consider first where you need to do your printing.

- Desktop printers connect to a laptop or tower computer through a cable, Wi-Fi or Bluetooth. Some models also let you enter information directly on a built-in keyboard. Desktop models can print labels up to 5 inches wide, and a few are designed to handle sizes up to 10 inches.

- Handheld and portable label printers are designed for job sites or warehouse use. These compact printers connect through Wi-Fi or Bluetooth and can handle labels up to 2 inches wide. They’re convenient if you need to print while moving through a facility.

Nearly all of these printers use one of two primary processes. Each process has advantages and best-use cases:

- Thermal transfer printing is most common. It uses ribbons filled with ink that transfer to the label. You can print one color at a time, but many color options are available. These labels hold up well in harsher environments, making them a good choice for floor marking tape or laboratory labels.

- Direct thermal printing doesn’t use ink. Instead, it prints on heat-sensitive labels that darken when run through a compatible printer. These printers only print in black, and the results can fade after a few months, so they are better for short-term needs.

Some printers only handle one process, while others are multi-use, so always check before choosing supplies.

Tips for Selecting Labels

Choosing the right label starts with the application. What do you need this label to do, and where? Do you need a general-purpose label for storage or inventory, or something more specific, like electrical panel labels?

For safety and compliance, integrated label and ribbon kits make it easy to print labels for arc flash, pipe marking, and ANSI caution, danger, notice, or warning headers. You can also choose pre-printed safety labels with common messages or blank labels that let you add your own directions.

Once you know the application, it's important to consider these characteristics:

Adhesion

- Permanent: Built to stay in place even in harsh environments. Trying to remove them may damage the surface.

- Removable: Best when labels need to change frequently. They stick well but come off cleanly.

- Repositionable: Can be removed and reapplied multiple times if the surface and environment allow.

Size

Labels can be as small as one-eighth of an inch, up to the size of a standard sheet of printer paper, with many options in between. Be sure to match the label width to what your printer can handle, or vice versa.

Format

Most labels come in rolls, but you can choose from:

- Continuous roll: Flexible sizing for many applications

- Roll in a box: Easy access and tear-off

- Cartridge roll: Includes a built-in ribbon for convenience

What to Look for in Ribbons

If you’re using a thermal transfer printer, you’ll need ribbons. Ribbons come in a range of colors. There are also a variety of label and ribbon kits available for arc flash, pipe marking, lean workplace and compliance labeling, so check compatibility to make sure you’re getting the right one for your job.

There are three main ribbon types:

- Wax: Best for shipping or retail labels. Most affordable but least durable.

- Wax/resin: Stronger than wax alone, suitable for warehouses, outdoor applications and rough handling.

- Resin: The most durable option. Provides resistance to heat, chemicals and UV exposure while providing the sharpest print quality.

Having the right combination of printers, labels and supplies on hand ensures you have everything needed to communicate hazards clearly, keep inventory organized and support a safer, more efficient workplace.

Safety Management

Understanding Sorbents: Choosing the Right Spill Control Supplies

Understand how sorbents work, how different spill kits are used and how to choose the right spill control supplies to help support safer cleanup and compliance.

![]() OUR LATEST KNOWHOW

OUR LATEST KNOWHOW

Building Maintenance

Wet Mopping vs. Dry Mopping: What’s the Difference?

When used correctly and in the right setting, wet and dry mops both offer different benefits. Learn how to use a wet or dry mop to properly clean and maintain your flooring.

The information contained in this article is intended for general information purposes only and is based on information available as of the initial date of publication. No representation is made that the information or references are complete or remain current. This article is not a substitute for review of current applicable government regulations, industry standards, or other standards specific to your business and/or activities and should not be construed as legal advice or opinion. Readers with specific questions should refer to the applicable standards or consult with an attorney.