10 Factors to Consider When Choosing a Fastener

By Grainger Editorial Staff 6/3/24

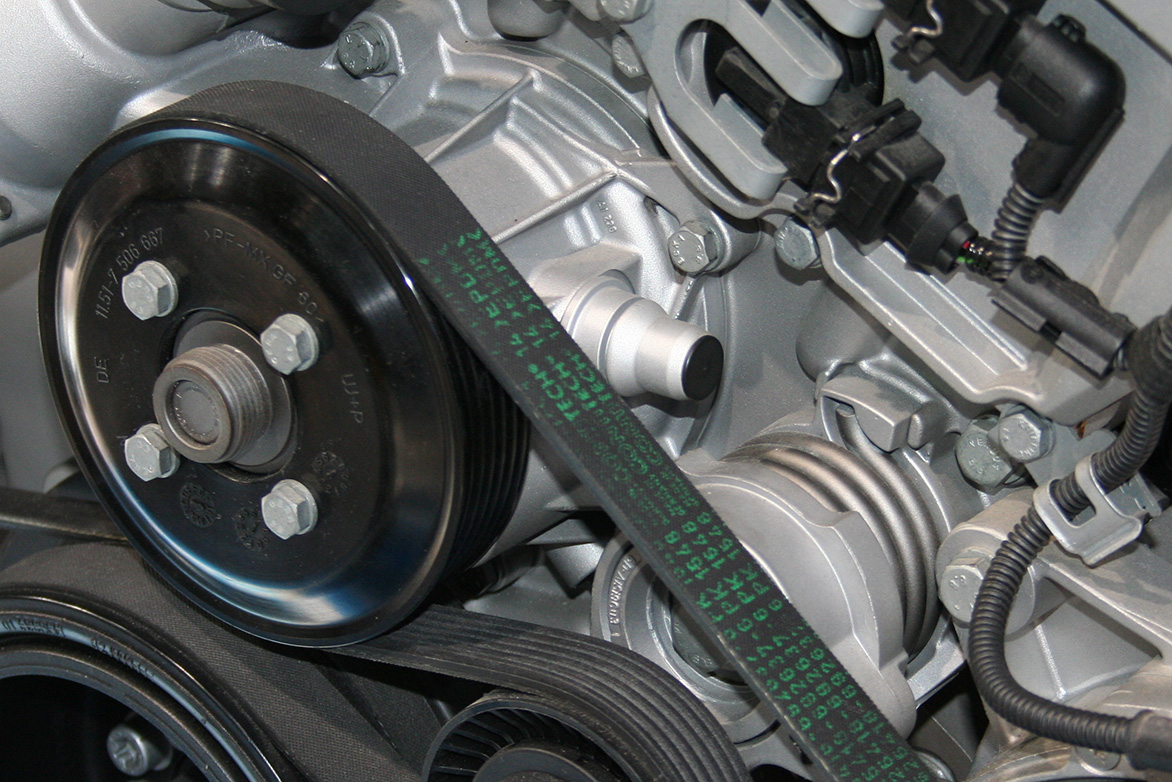

Fasteners play a critical role in safety, durability and performance across construction, automotive and industrial applications. Learn 10 key factors to consider when choosing the right fastener, from material and coating to size, compatibility and industry standards.

Fasteners are more than just hardware; they’re crucial for keeping everything from buildings and cars to planes and machinery securely together. Choosing the right fastener is incredibly important because it greatly impacts your projects’ safety, effectiveness and longevity. Each fastener has its own role and needs to be selected based on its use, environmental conditions and the materials it holds together. Picking the wrong fastener can lead to major problems like structural collapses, increased downtime and higher maintenance costs. Here are some key factors to ensure you pick the best fastener for the job.

1. Purpose and Functionality

First, consider how the fastener will be used. Will it be adjusted often, or is it meant to be a permanent fixture? Frequent adjustments require a strong fastener like those made from solid metal. A lighter material like plastic may be appropriate for places where the fastener isn’t adjusted often.

2. Assess the Environmental Conditions

The right fastener largely depends on the environment in which it will be used. Environmental factors like temperature, humidity, chemical exposure, vibration and UV light can all impact fastener performance and longevity. Choose materials that can withstand moisture, temperature fluctuations and chemical exposure for outdoor or demanding environments. Various materials, including metals and non-metal options, are designed for indoor use and less demanding environments.

3. Select the Right Fastener Type

Fasteners come in a wide variety of types, including bolts, screws, nuts, washers, rivets, anchors, inserts, rods, clips, pins and more. Each fastener has different variations to meet mechanical and structural needs, including:

- Bolts: Bolts are threaded fasteners that generally require a nut to join two or more components. They are available in different sizes and styles, including hex, carriage and eye bolts.

- Screws: Screws are designed with threads to be driven directly into materials like plastic, metal or wood. Common types include self-drilling, machine and wood screws.

- Nails: Nails are non-threaded fasteners typically used to join items through friction. They come in various types such as common, finishing, roofing, sinker and brad nails.

- Nuts: Nuts are used with bolts to form a strong connection. Examples include hex, lock and wing nuts.

- Washers: Washers are flat, thin discs placed beneath the heads of nuts or bolts. They help disperse pressure and help protect against surface damage and loosening over time. Common types include flat, lock, sealing, cushioning and countersunk washers.

- Pins: Pins are cylindrical fasteners that fit into holes to prevent relative motion between components. Examples include dowel pins and cotter pins.

- Anchors: Anchors permanently attach fixtures to concrete, masonry or drywall.

- Rivets: Rivets permanently join materials by clamping them together from the front and back. Rivets include blind rivets, solid rivets, tubular rivets, push-in rivets and drive-pin rivets.

4. Choose the Right Material

Selecting the right material for your fastener is critical to ensure it performs well under expected conditions. The material should match both the mechanical needs and environmental conditions. Common fastener materials include:

- Steel

- Stainless Steel

- Brass

- Bronze

- Aluminum

- Copper

- Nylon

- Plastic

5. Consider the Coating

Coatings are not just about improving appearance — they can also help extend the life of fasteners by enhancing their corrosion resistance. Fastener coatings include:

- Zinc: Provides good corrosion resistance for wet environments

- Galvanizing: Offers rust and corrosion protection for steel fasteners

- Chrome: Adds a shiny finish and great corrosion resistance

- Specialty Coatings: Used for specific industrial applications requiring additional protection against friction and environmental factors

6. Pick the Right Drive Type

When selecting a fastener, it’s important to consider the drive type since it determines the tools and force required for installation. Some of the most common drive types are:

- Phillips drive features a cross-shape for a secure connection.

- Flathead (slotted) are used when less torque is required.

- Torx (star-shaped) drives use a six-point star design, allowing higher torque without slipping.

- Hex Drive (allen) requires an Allen key or hex driver and is frequently used in furniture assembly and where space is limited.

- Square drives provide greater torque without stripping and are used with adjustable wrenches or 8-point sockets.

- One-Way drives are designed for permanent installation in one direction only and are used in security fixtures.

7. Determine the Correct Size

Choosing the right size and type of fastener helps ensure correct installation. Make sure to accurately measure thread size and pitch using a thread gauge or calipers to ensure compatibility with the corresponding nut or hole. The length of the fastener should fit the thickness of the materials being joined. It’s also important to choose the appropriate fastener shape and head style based on the project's specific needs, including the accessibility and torque requirements. Make sure the fastener will fit within the available space, taking into account any clearance needed for installation tools.

8. Check Compatibility

It’s important to consider several factors to help ensure fastener compatibility. First, determine if the fasteners can handle the expected loads to maintain a secure connection. You should also make sure that the fasteners fit properly with the types of joints and their configurations within the structure.

Compatibility between the fasteners and the materials they join is crucial for a reliable connection. Always consider the environmental conditions since using corrosion-resistant and weather-resistant fasteners can help improve their durability over time. To avoid galvanic corrosion, which happens when different metals contact each other and can increase deterioration, selecting fasteners made of the same or similarly resistant materials as the main structure is important. For instance, stainless steel fasteners should be used with stainless steel components to help prevent rust in harsh environments. Additionally, selecting the right fasteners and using proper lubrication can help address potential issues like galling, where high friction and pressure cause metals to fuse together.

9. Review Industry Standards

Fasteners are often designed to meet specific industry standards, including dimensions, strength ratings and material qualities. Familiarize yourself with ASTM, ISO and ANSI standards to ensure the fastener you choose is up to the task.

10. Plan for Maintenance

Think about how the fastener will be maintained. Will it need regular tightening? Is it in an easy-to-access location? Answering these questions up front can save time and help reduce costs later.

Choosing the right fastener is about more than just grabbing the nearest screw or bolt. It involves carefully assessing usage, environment, type, material, coating, size and applicable standards. By taking the time to consider each of these factors, you can ensure your project is secure, long-lasting and ready to meet environmental demands.

Frequently Asked Questions

Fastener length is measured differently depending on its design. For fasteners with the head above the surface, the measurement is from under the head to the tip. For countersunk fasteners, the measurement is from the head's surface point to the end of the fastener. For the diameter, measure the thicker part of the screw or bolt where the threads are. To find the thread count or pitch, use a thread gauge to count the threads per inch or measure the distance between them in millimeters.

Imperial, or standard, fasteners measure threading by counting the number of threads in one inch, called threads per inch (TPI). More threads per inch means finer threads. Metric fasteners, however, use thread pitch, which measures the distance in millimeters between two thread peaks. This tells you how close together the threads are; closer threads mean a finer thread. It’s important to use the right measurement system — TPI or thread pitch — when selecting nuts and bolts to ensure they fit properly and won’t damage each other.

Threaded fasteners, like screws and bolts, have spiral ridges or threads and are used with nuts or tapped holes. They are adjustable, making them ideal for assembling items that might need to be taken apart. Non-threaded fasteners, like rivets and pins, do not have threads and create permanent connections. They’re frequently used when components won’t need to be separated and require a strong, lasting hold.

Use precision measuring tools like calipers or thread gauges to ensure accuracy. Focus on measuring features like the length and thread pitch, specifically noting if the fastener has a special head type. Always consider the standards and manufacturer specifications for the fastener you’re dealing with to ensure proper fit and performance.

PPE in the Workplace

Safety Essentials: Protecting Employees and Supporting Compliance

Learn how the right safety supplies and processes can help support compliance, reduce injuries and protect employees throughout the workday.

![]() OUR LATEST KNOWHOW

OUR LATEST KNOWHOW

Equipment

5 Safety Eyewash Station Myths Debunked

Make sure you understand some of the common misconceptions about occupational eyewash stations so you can help your facility remain compliant.

The information contained in this article is intended for general information purposes only and is based on information available as of the initial date of publication. No representation is made that the information or references are complete or remain current. This article is not a substitute for review of current applicable government regulations, industry standards, or other standards specific to your business and/or activities and should not be construed as legal advice or opinion. Readers with specific questions should refer to the applicable standards or consult with an attorney.