Don't Blow It: 3 Common Fuse Mistakes

By Grainger Editorial Staff 10/14/25

Fuses protect valuable equipment, but common mistakes can cause damage and downtime. Watch out for these key errors and prevent them with these tips.

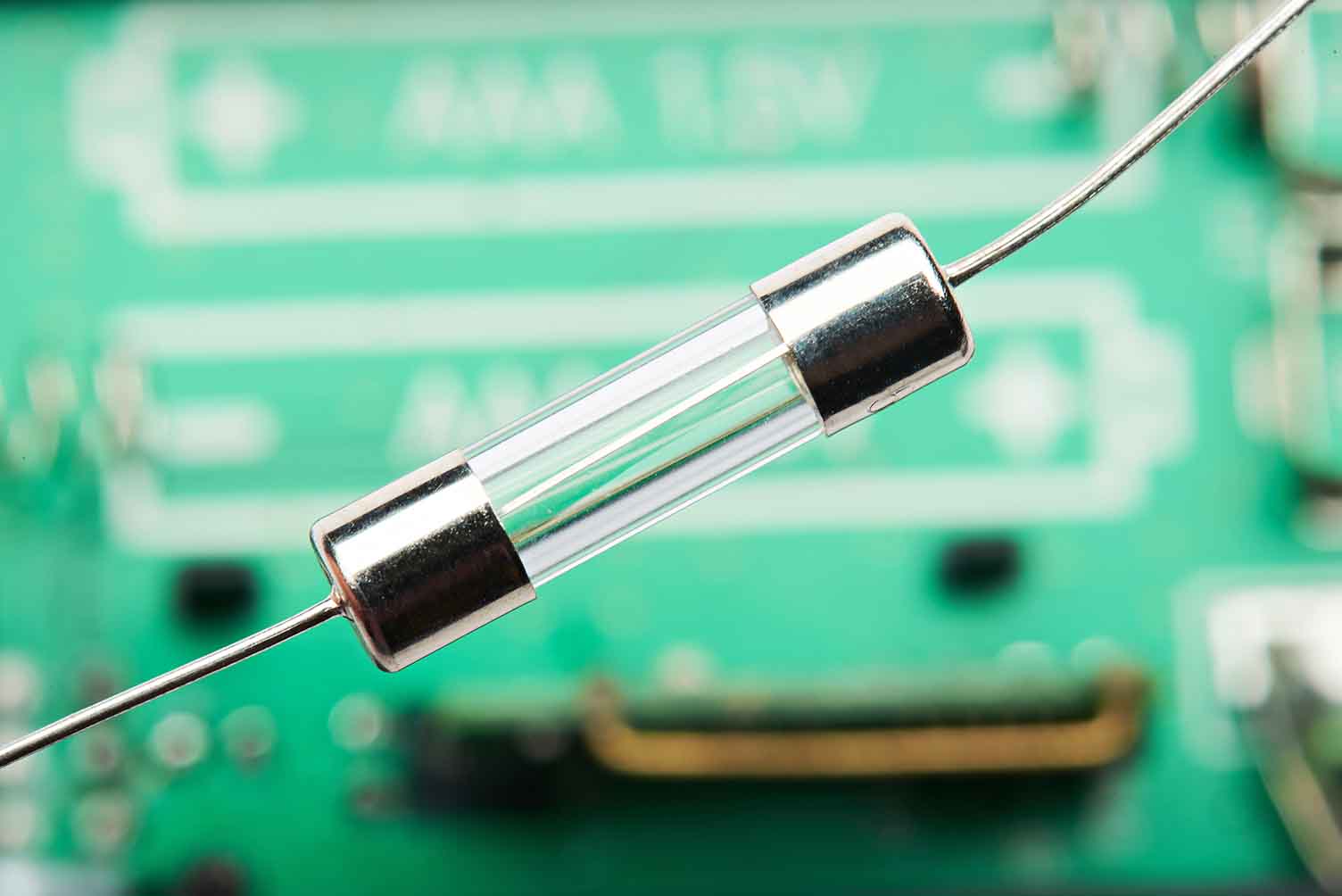

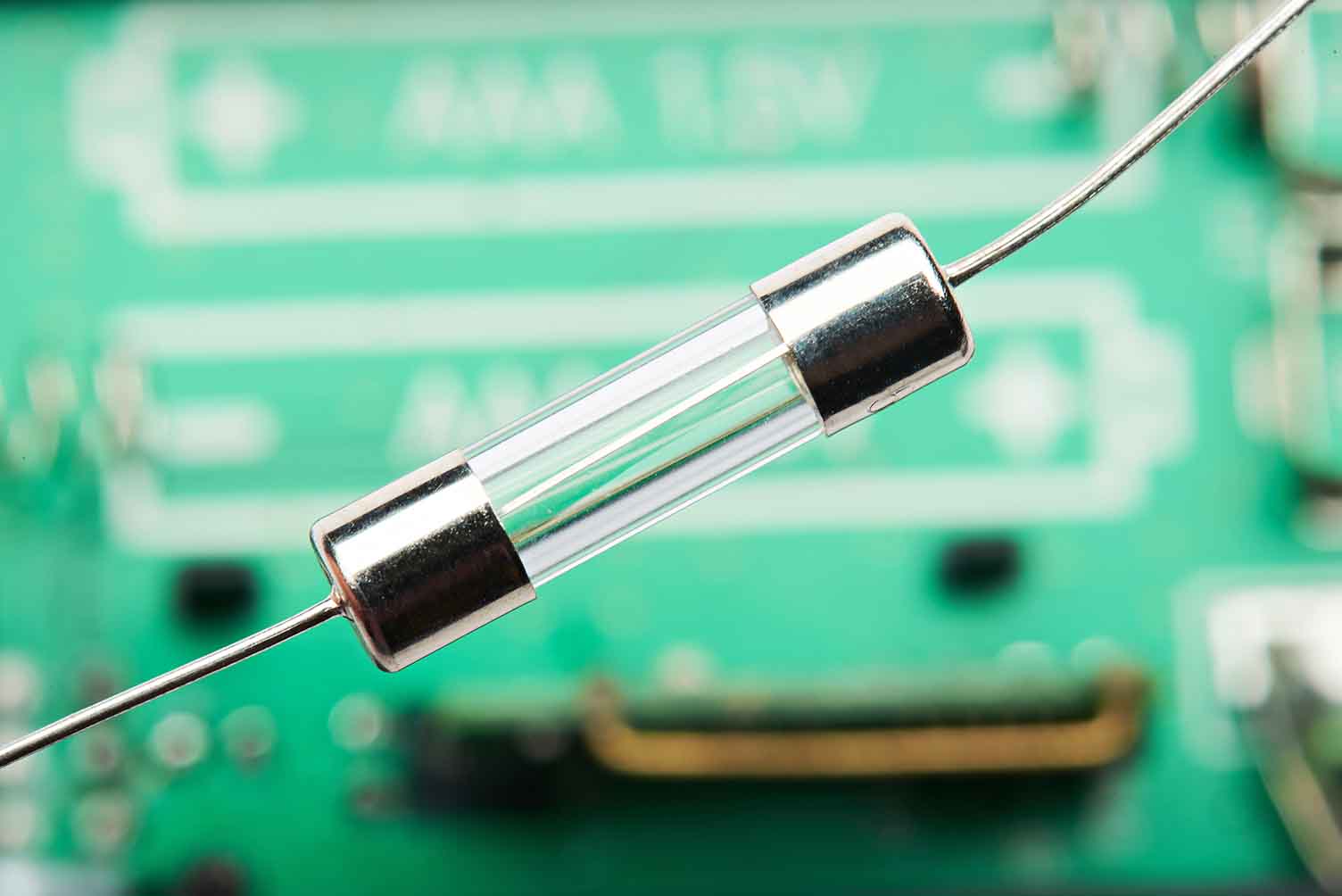

Fuses might be small, but they do incredibly important work. In a large industrial plant, those inexpensive bits of metal, glass, ceramic and plastic might be protecting multimillion-dollar machinery. When it comes to fuses, bad practices can lead to costly equipment damage, facility downtime and safety hazards.

Fortunately, you don't have to be an electrical engineer to know how to prevent some of the most common problems. In fact, some big mistakes involve routine storage, handling and maintenance practices. Here are three fuse mistakes that are easy for anyone to see and fix.

Mistake #1: Not Sorting and Labeling Inventory

Two fuses can look similar but behave very differently if they're in different classes or have different ratings. You don't want an RK1 when you need an RK5. It's important to use the right replacement fuse.

If incompatible fuses are stored together in the same bin, a technician might easily grab one that looks about right but isn't a perfect match. And when fuse storage areas are unlabeled, it can take much longer for people to find the exact fuse they need. Rushed employees may be more likely to grab the one that looks close enough without reading the product labels carefully.

Tip: Sort fuses by class and amperage or current rating into well-labeled bins, drawers or boxes. This will make it easy to find the exact fuse for every situation, as quickly as possible. You can set up an inventory control worksheet with detailed location information to make retrieval even easier.

Mistake #2: Not Regularly Inspecting Fuses

Preventive maintenance helps keep the power flowing by anticipating problems before they happen.

National Fire Protection Association (NFPA) standard 70B offers guidance on electrical maintenance practices and includes information on how to inspect fuse terminals, fuse clips and fuse holders during preventive maintenance.

Tip: According to NFPA 70B, items should be checked for discoloration from excessive heat, poor contact or corrosion. Include these checks as part of regular preventive maintenance. Don't assume that if it isn't blown, it's OK. You can also use IR (infrared) imaging for early detection of overheating.

Mistake #3: Ignoring Worn or Damaged Fuse Holders

When a fuse blows, it’s easy to assume that you just need to find and replace that fuse. But occasionally the fuse holder can become a problem, too. Over time, the clips that hold the fuse in place can lose their spring tension. If they're too loose, the holder can't maintain solid contact, leading to increased resistance, excess heat and possible fuse failure. Dirt, dust and oxidization on the contacts can cause similar problems.

Tip: As part of preventive maintenance or when replacing a fuse, always inspect the fuse holder, too, as described in NFPA 70B. Look for discoloration or other signs of overheating. Check that the clips still grip the fuse blades firmly and that the fuse sits securely in the holder. A good fuse in a bad holder is still a problem waiting to happen.

PPE in the Workplace

Safety Essentials: Protecting Employees and Supporting Compliance

Learn how the right safety supplies and processes can help support compliance, reduce injuries and protect employees throughout the workday.

![]() Our Latest KnowHow

Our Latest KnowHow

How to Choose the Right Ceiling Tiles

Ceiling tiles are made of different materials to serve a variety of purposes, so make sure you're choosing the right kind of ceiling tile for your facility.

The information contained in this article is intended for general information purposes only and is based on information available as of the initial date of publication. No representation is made that the information or references are complete or remain current. This article is not a substitute for review of current applicable government regulations, industry standards, or other standards specific to your business and/or activities and should not be construed as legal advice or opinion. Readers with specific questions should refer to the applicable standards or consult with an attorney.