Guide To Choosing Lockout/Tagout Devices

By Grainger Editorial Staff 1/12/23

Lockout/Tagout is the name for a protection system used to prevent unintentional exposure to hazards associated with specific types of machinery and equipment.

Lockout/Tagout (LOTO) devices are used to prevent equipment from being accidentally powered on during maintenance and repairs in order to protect workers. They're commonly used on machinery, electrical equipment, vehicles, plumbing systems and other mechanical devices.

Failure to correctly follow LOTO procedures or use the equipment properly is one of the most common causes of workplace electrical accidents.

Some LOTO devices fit specific equipment such as steering wheels. Electrical lockouts keep circuit breakers, plugs and switches secured. Flange lockout devices conceal flange bolts to prevent access during pipeline maintenance.

What Are the Different Lockout/Tagout Devices?

Choosing the right type of lockout device starts by knowing the many types available so you can choose the most effective option for your needs. Here's a sampling of some common types of LOTO devices and their purposes.

Lockout padlocks are used to add extra security at a lockout point. These can be keyed alike or different depending on the application. They are in multiple colors, though there is no industry-wide standard for how the colors are used. Lockout padlocks are used to lock LOTO devices.

Electrical lockouts are used to protect workers from accidental exposure to hazardous electrical energy releases.

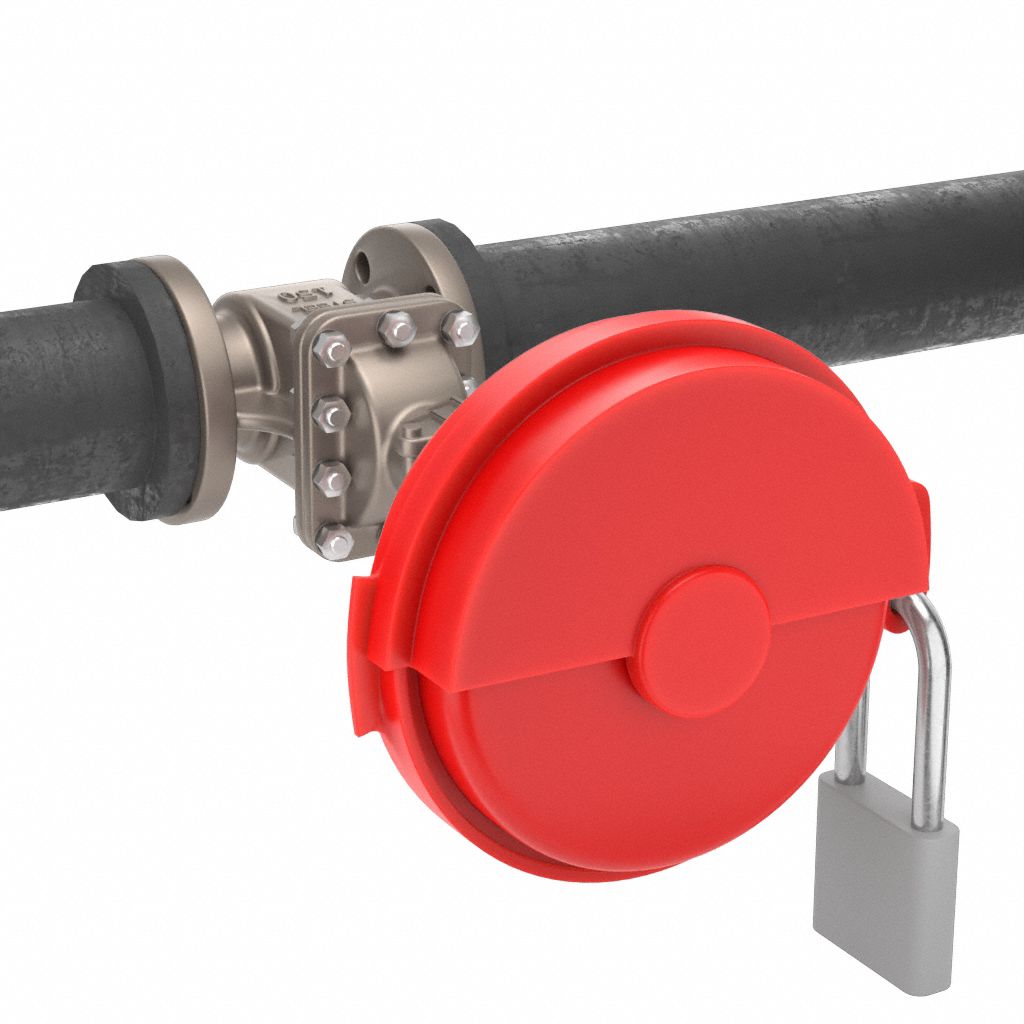

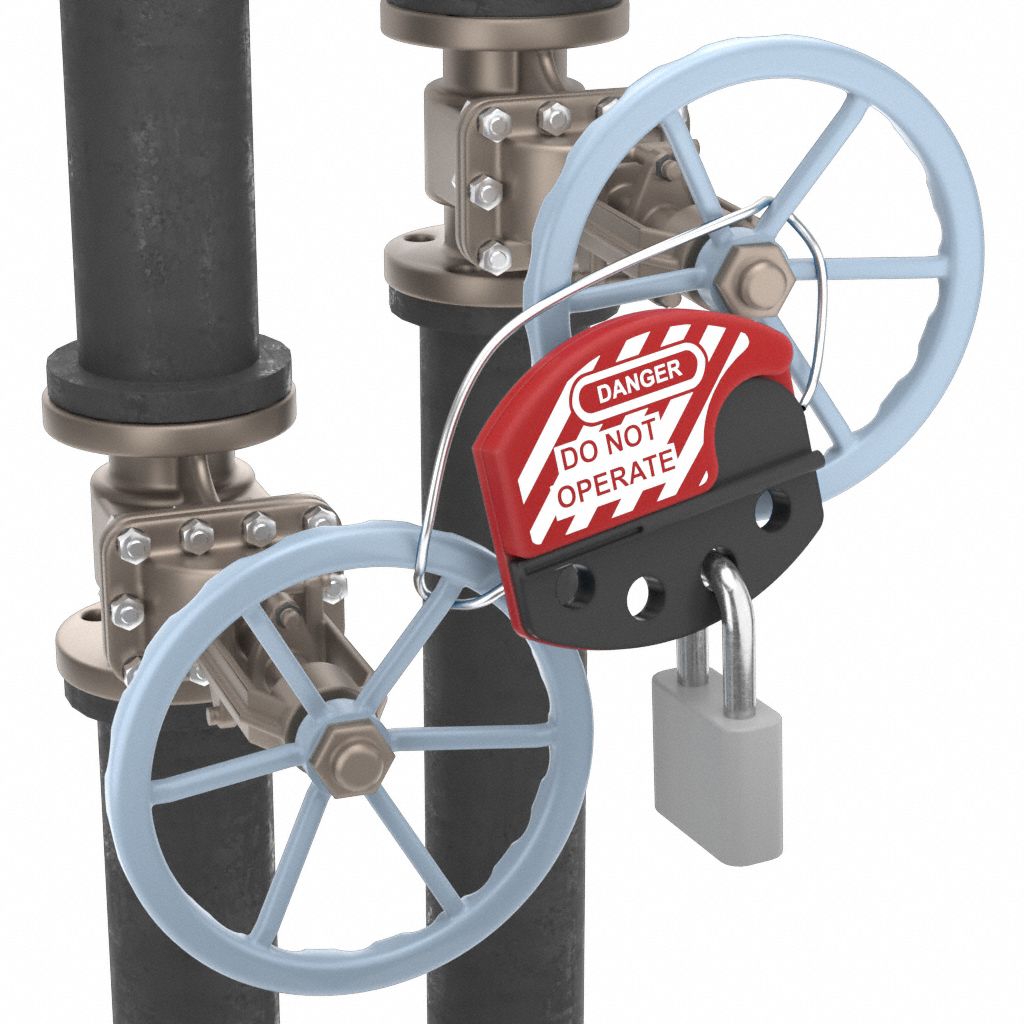

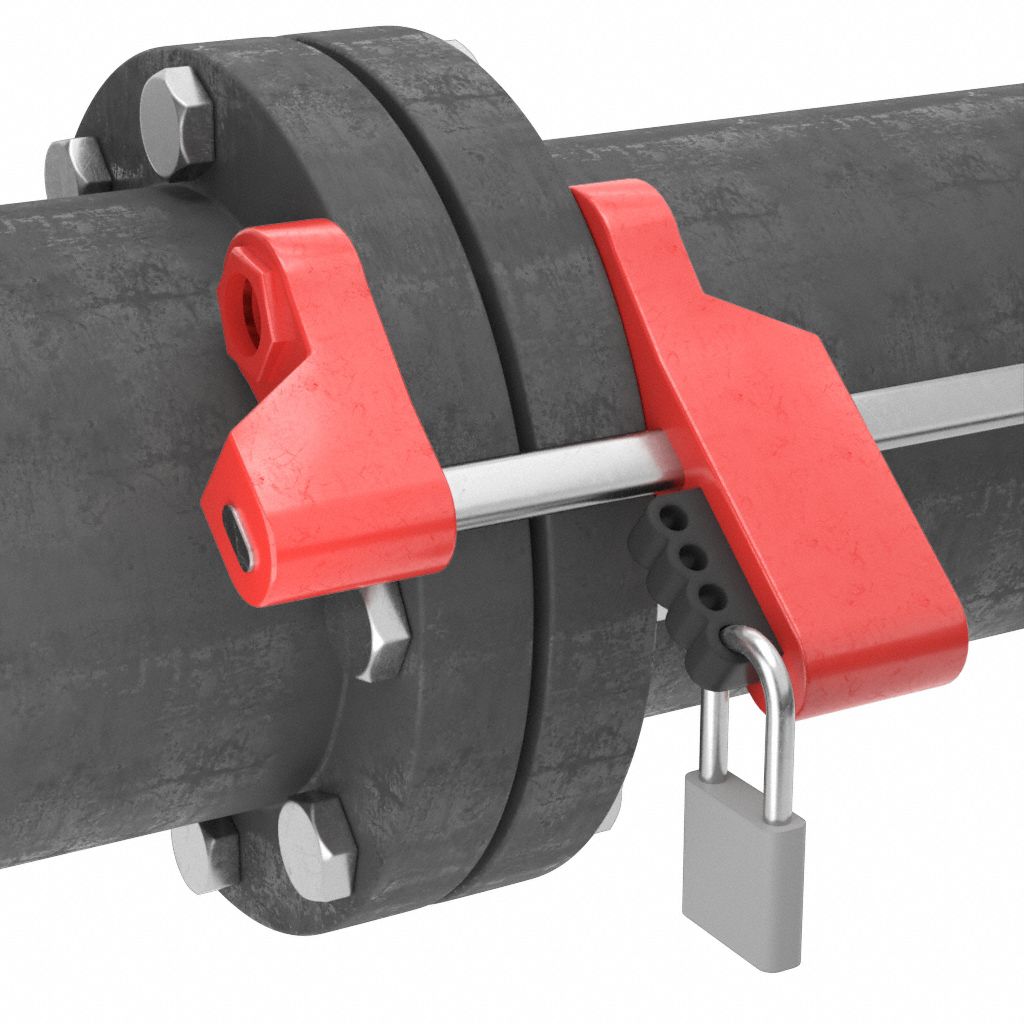

Valve lockouts are used to switch off pressurized, valve-operated machinery while workers perform maintenance.

There are models specifically designed for ball, butterfly and gate valves.

Cable lockouts flex around difficult-to-lock devices such as handles and gate valves.

Cable lockouts are ideal for commercial or industrial use.

Steering wheel lockouts attach to a vehicle's steering wheel to warn users that a vehicle is not in operation or is currently being serviced and should not be used.

These covers do not actually disable a steering wheel, though many have a grommet hole that allows a padlock to be added.

Flange lockout devices conceal flange bolts to prevent entry to the blind on pipelines.

They can be removed when work is completed.

Gas cylinder lockouts are available in a variety of types.

Most feature access to the valve handle of a gas cylinder, while preventing access to the main cylinder.

Pneumatic lockouts prevent pneumatic fittings from being connected to a pressurized air source, preventing air compressors and other machinery from operation.

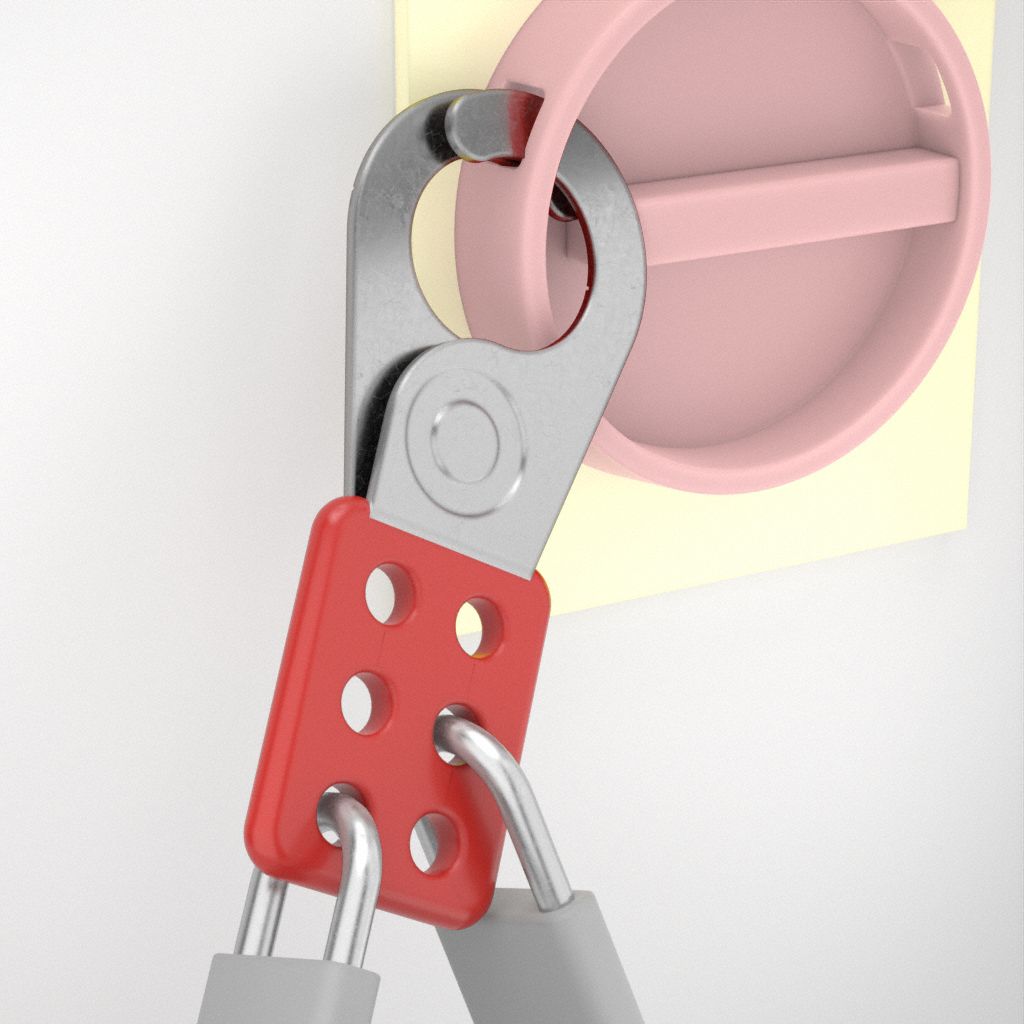

Lockout hasps are used when multiple people are servicing the same equipment.

These hold several padlocks at one time, adding an extra level of safety by requiring multiple authorizations for access to one locked-down device.

Group lockout boxes are used when multiple people are servicing the same equipment.

These lock boxes store keys and other access to equipment to prevent startup during maintenance.

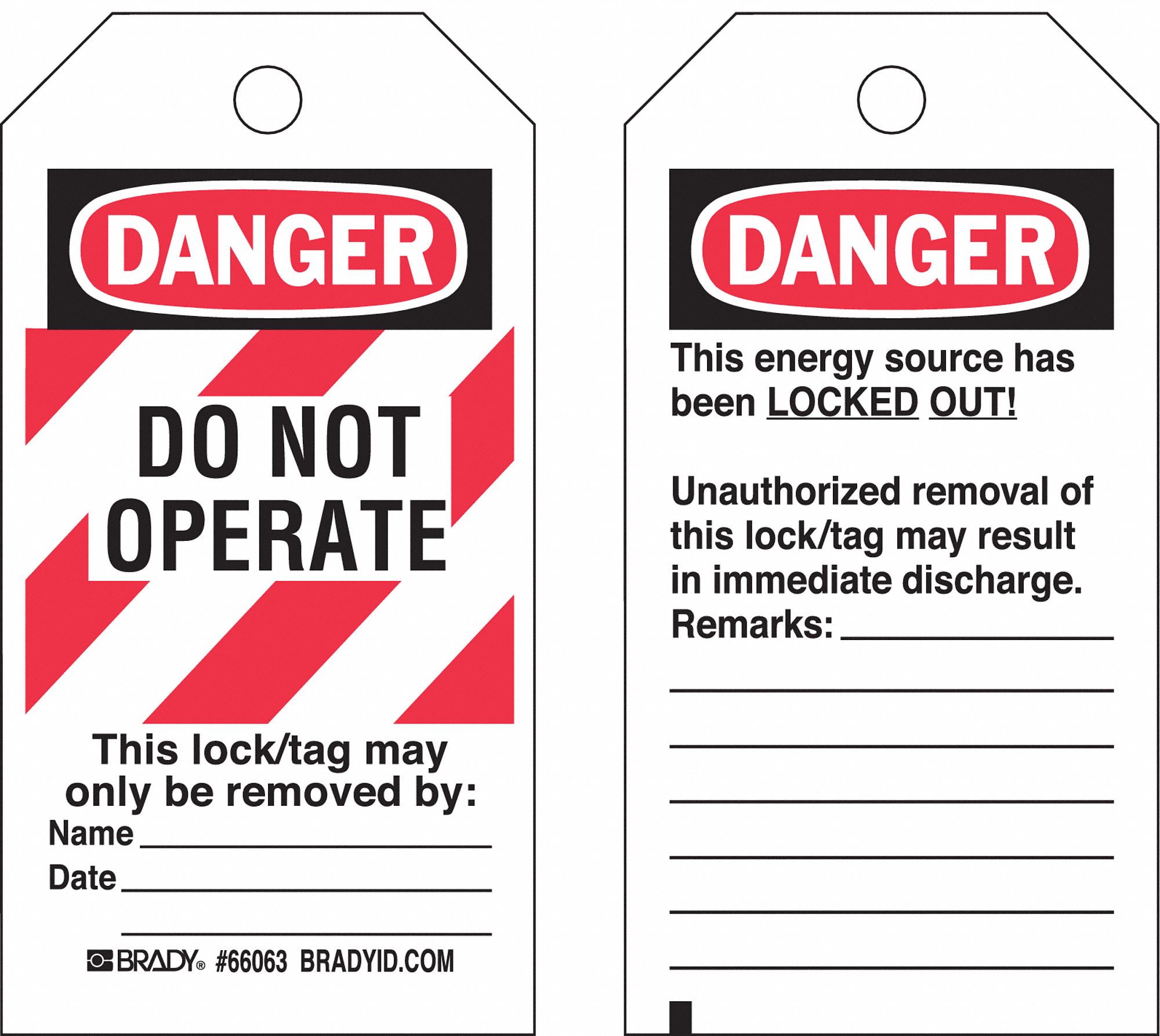

Tagout tags, also called lockout signs and labels, are used to remind people to use appropriate LOTO procedures.

These are also used to indicate when equipment is locked out.

Lockout stations and kits are easy to identify and store a variety of LOTO devices.

These stations make it convenient for workers to find the LOTO supplies they need in one location. They can be stationary or portable for job sites.

Confined space covers are used to prevent entry to permit-required confined areas. These covers are also effective at protecting areas from weather damage and pests.

Get more practical KnowHow on LOTO and worker safety here.

PPE in the Workplace

Safety Essentials: Protecting Employees and Supporting Compliance

Learn how the right safety supplies and processes can help support compliance, reduce injuries and protect employees throughout the workday.

![]() Our Latest KnowHow

Our Latest KnowHow

How to Choose the Right Ceiling Tiles

Ceiling tiles are made of different materials to serve a variety of purposes, so make sure you're choosing the right kind of ceiling tile for your facility.

The information contained in this article is intended for general information purposes only and is based on information available as of the initial date of publication. No representation is made that the information or references are complete or remain current. This article is not a substitute for review of current applicable government regulations, industry standards, or other standards specific to your business and/or activities and should not be construed as legal advice or opinion. Readers with specific questions should refer to the applicable standards or consult with an attorney.