Diagnosing Power Tool Problems: 5 Warning Signs and What They Mean

By Grainger Editorial Staff 2/23/23

Like most heavy-use equipment, power tools fall victim to wear and tear, malfunctions and electrical issues. Even when the best tool maintenance is carried out, tools can stop working and need immediate inspection and possibly repair. If you’ve experienced a belt sander smoking or a miter saw squealing, then you know tool malfunction is not something to take lightly.

However, with some careful examination, you can diagnose the cause of the issue and determine the next course of action. Check out these five red flags and how to properly inspect your tools for repair.

Remember, always make sure your power tool is disconnected from the power source before your try to diagnose any potential problems.

1. It Won't Start

If your tools won’t start, it could hint at some larger electrical problems including a short or part malfunction.

- Start by asking yourself these questions: Is the tool plugged into the right power source? Am I using the right air pressure for a pneumatic tool? Am I using a compatible battery (on a cordless tool)? Power sources for cordless tools aren't interchangeable. Make sure you're using the right voltage and brand battery for the tool. (Try this 10-question power tool battery quiz and test your knowledge.)

- Check the power switch and its assembly to make sure there is no damage as heat and water damage can be the culprits of a tool that won’t start. Using a multimeter can test the voltage on your tool to assess if power is moving through the cord, switch and to the parts of the tool.

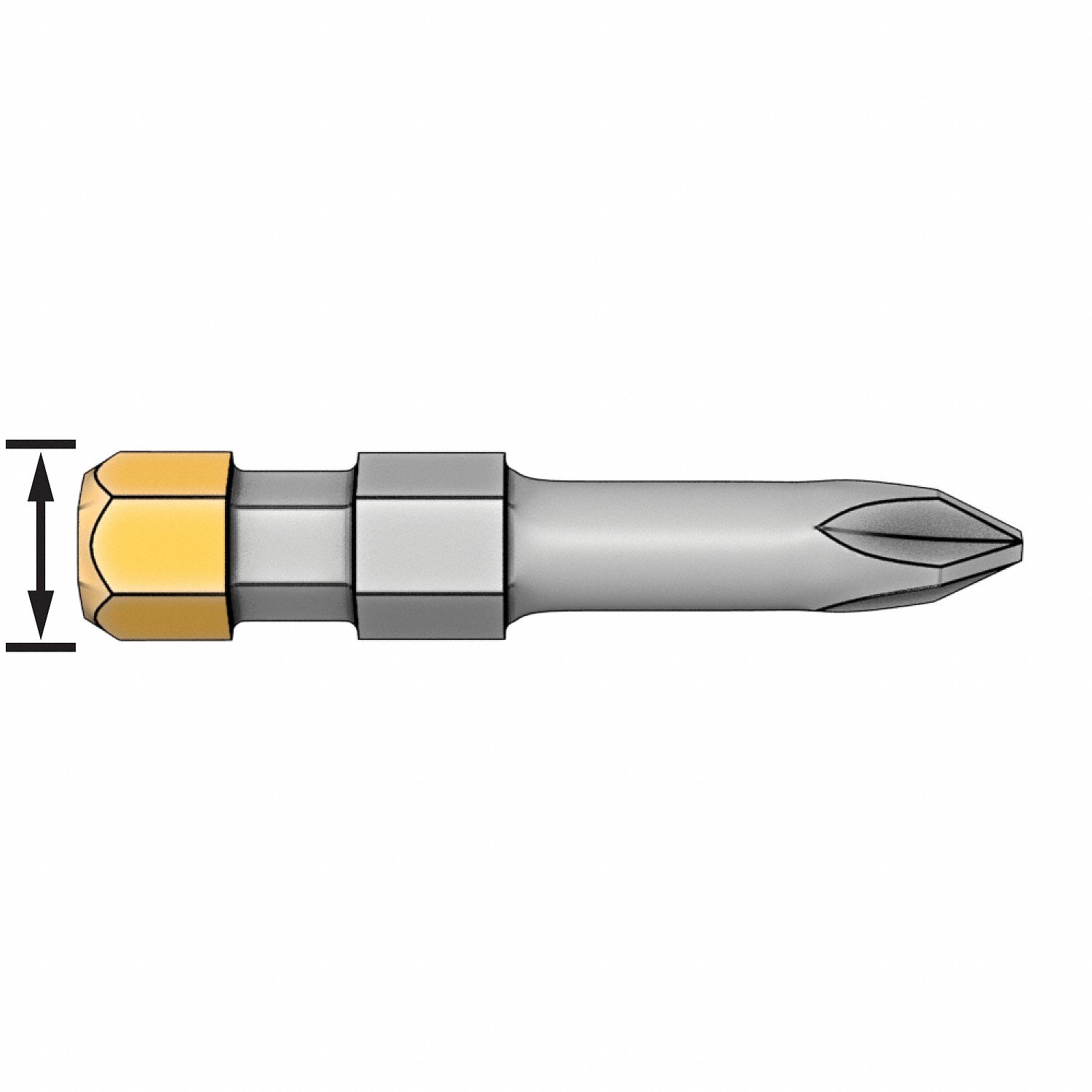

- Dust and dirt accumulation within a tool can also prevent it from working, so brushes and springs are where you should look next. Brush channels— enclosures consisting of brushes and springs located at the end of a motor where electricity is routed—can become worn and shorten over time. Check your brushes for wear and replace accordingly.

- A bad power cord is another visible issue that can be replaced. Kinks, tears or cuts in cords can stop the flow of electricity to the power switch and can be assessed using a multimeter which will indicate if a wire is broken.

2. Weakened Power

Your tool starts but the power level is so weak that you’d probably be better off with a manual screwdriver. Or handsaw. Or bicycle pump. When your power tools lose their oomph (and it’s not a low battery), the most likely cause is old, worn carbon brushes that need replacing. The carbon brushes are the small carbon blocks that transfer the electrical current from your power source to the tool’s motor itself. These wear out through use. If your tool is losing power and doesn’t have the speed or strength it should, it could be an indicator that it is time to replace these parts. More cordless power tool manufacturers are using brushless motors in their products. This might be a good consideration if you're in the market to replace a cordless tool.

- Similar to a tool that won’t start, check your carbon brushes for any heavy wear or signs of damage.

- Consider brushless motor tools if this is a persistent problem.

- If your brushes are clear, there may be damage to your tool’s commutator or the rest of the assembly. Discoloration, buildup and even melted insulation are signs that these parts are the root cause.

3. Burning Smell

Malfunctioning motors tend to give off a very recognizable burning smell when something is wrong. Everything is still spinning but the tool is no longer working, and it just stinks.

- Diagnosing this smell could change depending on the age, type and design of your power tool. According to Instructables Workshop if your tool has a drive belt—like a sander or a planer—that is the first place to check.

- Are you using the right tool and accessory? Some saws or blades are designed specifically for wood and others for various types of metal. If you’re not using the correct tool and accessory you’re probably doing the work inefficiently and harming your investment. Double-check that you're not overworking your tools by using incompatible accessories.

- When the drive belt breaks, you will get that tell-tale burning smell, and your tool will stop working even though the motor is still running.

- For other tools, such as power saws, you may want to check if the capacitors need replacing.

- It could also just be a case of the tool overheating. Motors generate a lot of heat when in use. If the tool has been running too long or too hard, the tool can overheat and cause a burning smell. For best power tool safety, immediately turn off any power tool that is emitting a burning smell and let it sit for about 30 minutes before attempting to diagnose the problem.

4. High-Pitched Screeching Noise

Using power tools can be pretty loud. However, sometimes a power tool starts making a high-pitched screeching noise, or screaming; that goes above and beyond the loud hum of your electric hammer drill.

- If your tool starts making this noise, first make sure that it is properly lubricated. Check the manufacturer’s specifications for maintaining your tool to find out the best method to keep your tool lubed.

- Another easy tip for a squealing tool is to check the gears. If your tool has a forward and reverse control (as most power drills do), your gear switch may get stuck between the gears. Gently move the switch back and forth and try running the drill again.

5. Sparks and Smoke

If your power tool begins to emit smoke or sparks, turn it off immediately. You should never continue using power tools that are smoking or sparking. Unplug the tool, set it aside, and allow it to cool down before attempting to diagnose or fix an issue.

- Once the tool is cooled, check to see if any dust or debris has gotten into the tool. Sawdust or other particles that frequently fly through the air in heavy work areas can get into your tool’s vent and cause that sparking or smoking.

- If your tool is free of burning debris, you may need to take apart the tool’s casing and check for heat damage. Check your tool's brushes, motor, and battery or replacement battery.

Power Tool Maintenance

The best way to avoid issues with your power tools is to take proper care of them with routine maintenance. Be sure to follow manufacturer’s recommendations for caring and keeping your tools. For optimum performance, make sure you're using all compatible accessories and power sources. Following a regular maintenance plan is usually the best way to head off potential problems before they start. Many common tool problems can be solved with simple checks and adjustments to determine if upgrades are available for your company’s needs.

PPE in the Workplace

Lanyards vs. SRLs: Understanding Fall Protection Systems

Shock-absorbing lanyards and self-retracting lifelines both protect against falls, but they work differently. Learn how movement, clearance and system design affect each one.

![]() Our Latest KnowHow

Our Latest KnowHow

Are You Using the Best Cleaning Cloth for the Task?

It's easy to get into the habit of using the same basic cloths for most cleaning tasks. Consider these options for better, more efficient ways to trap dirt and dust throughout your facility.

The information contained in this article is intended for general information purposes only and is based on information available as of the initial date of publication. No representation is made that the information or references are complete or remain current. This article is not a substitute for review of current applicable government regulations, industry standards, or other standards specific to your business and/or activities and should not be construed as legal advice or opinion. Readers with specific questions should refer to the applicable standards or consult with an attorney.