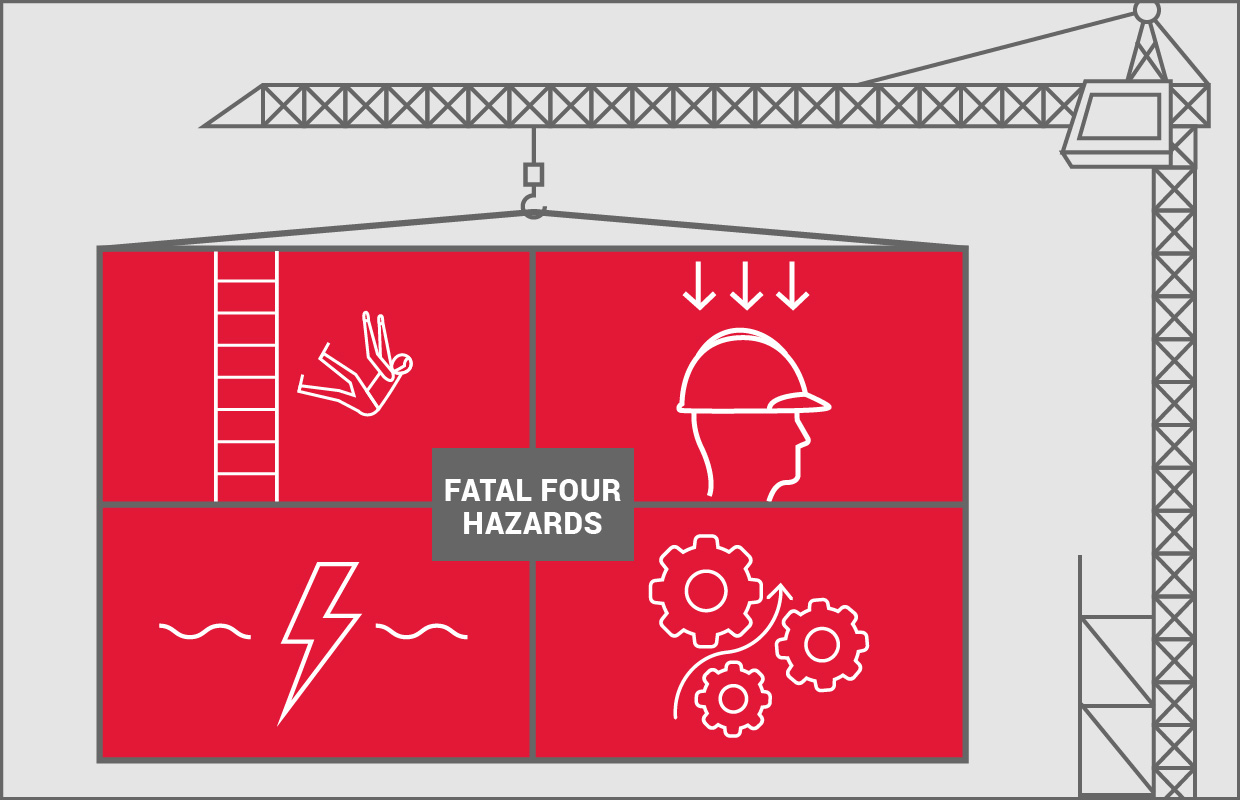

How to Prevent OSHA's Fatal Four on Construction Sites

By Grainger Editorial Staff 7/1/19

The "fatal four" hazards in the construction world may be the industry’s leading causes of injury and death, but safety managers can lessen these threats and keep their workers safe from harmwith good planning, awareness, and the right protective equipment.

Construction is one of the deadliest industries for workers, and OSHA created the Focus Four to highlight the primary causes of injury and death in construction. One-in-five worker deaths in the U.S. occur in the construction industry, so the following four hazards need to be a major concern point for all safety managers:

- Falls: Fall hazards include unprotected sides or holes, improperly constructed walking or working surfaces, and failure to use proper fall protection; falls accounted for 384 out of 991 total deaths in construction in 2016.

- Object Strikes: These include falling objects due to rigging failure, loose or shifting materials, equipment malfunctions, and vehicle or equipment strikes; strikes accounted for 93 total fatalities in 2016.

- Electrocutions: These are caused by contact with overhead power lines or live circuits in panels, poorly maintained cords and tools, and lightning strikes; there were 82 electrocutions in 2016.

- Caught-in/between: This categorization includes construction workers who are killed when caught in or compressed by equipment or objects, as well as the hazards of being struck, caught, or crushed in a collapsing structure, equipment or material. In 2016, there were twototal fatalities from this hazard.

Minimizing Fall Hazards

Fall hazards are present at most worksites, OSHA reports in its “Focus Four: Mitigating Jobsite Hazards,” publication, with many workers exposed to these hazards on a daily basis. Because workers are at risk any time they are working at a height of four feet or more, OSHA generally requires that fall protection be provided for an employee working at a height of six feet. And regardless of the fall distance, fall protection must be provided when working over dangerous equipment and machinery.

To prevent falls, safety managers should make sure their employees always:

- Wear and use personal fall arrest equipment.

- Install and maintain perimeter protection.

- Cover and secure floor openings and label floor opening covers.

- Use ladders and scaffolds safely.

Reducing Struck-By Injury Rates

Produced by forcible contact or impact between the injured person and an object or piece of equipment, struck-by injuries typically involve flying, falling, swinging, or rolling objects. To better prevent struck-by incidents, employees should wear appropriate PPE, stay alert of heavy equipment, and stay clear of lifted or suspended loads.

Workers should also:

- Check vehicles before each shift to ensure that all parts and accessories are in safe operating condition.

- Never drive a vehicle in reverse gear with an obstructed rear view (unless that vehicle has an audible reverse alarm or another worker signals that it is safe).

- Always properly secure loads with appropriate rigging.

- Make sure that all tools and equipment are securely attached and/or tethered.

Preventing Caught-in/Between Accidents

Caught-in/between accidents involve those individuals who get caught or crushed in operating equipment, between other mashing objects, between a moving object and a stationary object, or between two or more moving objects. Cave-ins, trenching, and being pulled into or caught in machinery and equipment (including strangulation as the result of clothing caught in running machinery and equipment) all fall under this OSHA Focus Four category.

To prevent caught-in/between accidents, safety managers should ensure that their employees:

- Always use machinery that is properly guarded.

- Use other methods to ensure that machinery is sufficiently supported, secured, or otherwise made safe.

- Never enter unprotected trenches or excavations that are five feet or deeper without an adequate protective system in place (some trenches under five feet deep may also need such a system).

- Make sure the trench or excavation is protected either by sloping, shoring, benching, or trench shield systems.

Reducing the Chances of Electrocution

Electrical workers have the most electrocutions per year, with the most serious concern being working “live” or near live wires. Proper protocol includes de-energizing and using lockout/tagout procedures. Among non-electricians (e.g., construction laborers, carpenters, supervisors of nonelectrical workers, and roofers), failure to avoid live overhead power lines and a lack of basic electrical safety knowledge are the major concerns.

To prevent electrocutions, safety managers should make sure their workers:

- Locate and identify utilities before starting any work.

- Look for overhead power lines when operating any type of equipment.

- Maintain a safe distance away from power lines.

- Learn the safe distance requirements.

- Avoid operating portable electric tools unless they are grounded or double-insulated.

- Use ground-fault circuit interrupters for protection.

- Be alert to electrical hazards when working with ladders, scaffolds or other platforms.

Safety Starts at the Top

To promote safety on the jobsite and reduce the consequences of OSHA’s Fatal Four, companies can use the proactive steps outlined in this article to engage their workforces and make sure employees go home safely to their families every night. Building a commitment to safety starts at the top, where senior management can set the best example by making safety the centerpiece of the organization’s strategic planning efforts

![]()

The information contained in this article is intended for general information purposes only and is based on information available as of the initial date of publication. No representation is made that the information or references are complete or remain current. This article is not a substitute for review of current applicable government regulations, industry standards, or other standards specific to your business and/or activities and should not be construed as legal advice or opinion. Readers with specific questions should refer to the applicable standards or consult with an attorney.