10 Tips for Winterizing Your Fleet

By Grainger Editorial Staff 10/6/22

When temperatures begin to fall, it's time to perform a winter maintenance check on your vehicles and outdoor engines. Winter weather can be especially harsh on the vehicles you depend on every day. If you're running a business in a cold weather climate that relies heavily on vehicles, here's a 10-point checklist to help you get your fleet ready for winter's worst.

1. Don't run low on gas

Gas tanks should always be at least half full during cold weather. This is primarily because if your tank is more than half empty, water vapor can collect in the bottom of your tank. When drawn into your engine’s fuel line, water vapor can freeze in the winter and prevent your engine from starting. Adding a bottle of gas-line antifreeze to your gas tank combines with the water so it can be burned for fuel.

2. Check the oil for lower temperatures

As the temperature drops, it's important to make sure you are using the right viscosity of motor oil. Viscosity is a measurement of an oil's resistance to flow. In colder months, viscosity increases because oil thickens. In especially cold climates, even oil with a viscosity of 10W-30 can be too thick. Double-check the owner's manuals for all of your vehicles to make sure you're using the recommended viscosity for freezing temperatures.

3. Inspect belts for wear

Just as heat and everyday driving can cause wear and tear on your vehicle's belts, so can cold weather. A worn timing or v-belt could cause a vehicle breakdown, something you definitely want to avoid to minimize downtime or if you have employees potentially driving in remote areas. Make a belt inspection part of your regular vehicle maintenance routine and check for signs of fraying or cracking. Change any worn belts immediately.

4. Check fluid levels

The best time to check and top off your vehicle's fluids is before the harsh winter weather hits. Check and top off engine coolants, power steering, brake, windshield washer and battery fluids.

5. Check and clean spark plugs

If your engine misfires or simply doesn't want to start, it could be the spark plugs. And while spark plugs aren't expensive, try cleaning first before replacing them. There are many ways to clean spark plugs, but using a carburetor cleaner and a wire brush is a common solution. Clean spark plugs will run just like new if the plug's integrity hasn't been compromised.

6. Check and clean batteries

In the winter cold, when you really need extra power, your battery might not be up to the task. Consider replacing a battery that is more than 3 years old. Keep the contacts free of corrosion with a battery post and terminal cleaner.

7. Inspect wiper blades

Vehicle windshields get messy in winter weather. Make sure drivers are able to clear windshields effectively with proper maintenance. Inspect wiper blades for fraying or cracking and consider using heavy-duty winter blades for tough ice buildup.

8. Switch to winter tires

If your vehicles operate in a cold region with snow and ice, all-weather tires may not offer the best performance. Consider outfitting your fleet with winter tires instead. They offer better traction in icy conditions and even on cold, dry roads.

9. Make sure lights are fully operational

In the darker winter months, it’s important to be seen by other drivers, and to be able to see everything around you while driving. Walk around your vehicle to make sure all lights and turn signals are cleaned and working properly.

10. Check brake pads and shoes

With slippery winter road conditions, having brakes in working order is a top priority. If your brakes make a high-pitched squealing sound when engaged, it's time to change them out for a new pair. Other signs of worn brakes include vibrations when depressing the brake pedal, leaking fluid or a burning smell when using the brakes.

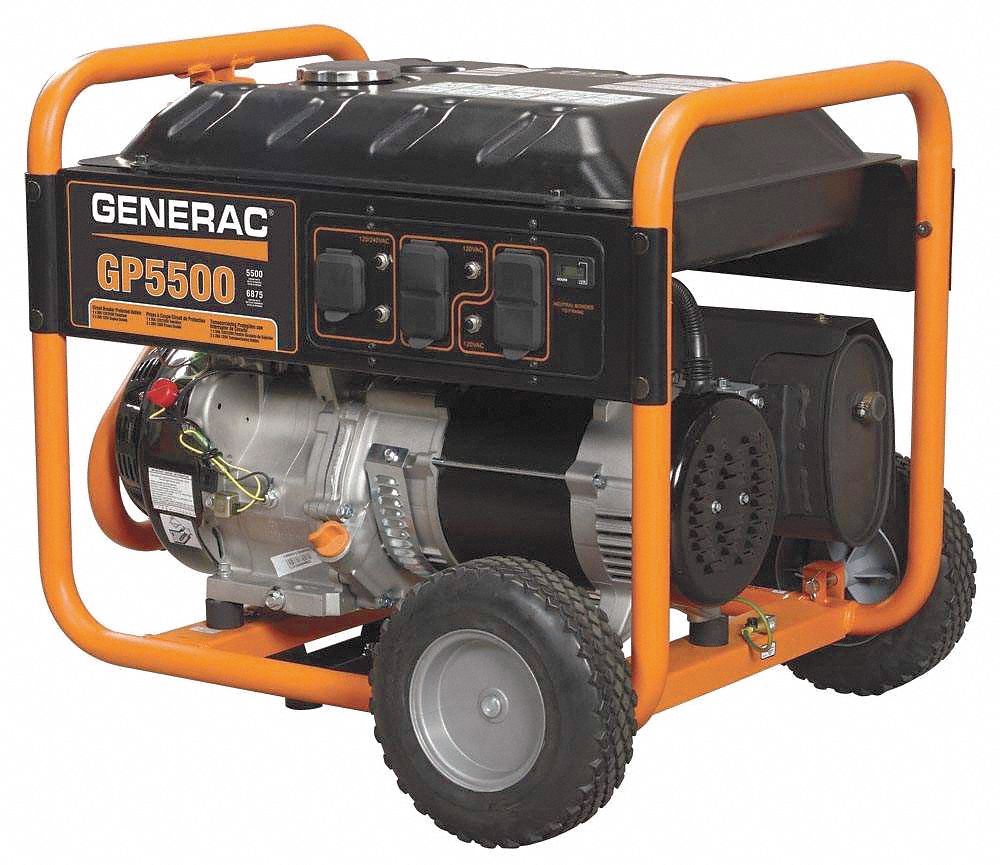

Equipment Engine Maintenance

It’s important to also keep other equipment running through the winter season. Snow throwers, generators and other two- and four-cycle engines may not be used for long periods of time. As a result, the fuel may form gum and varnish deposits.

In less than 60 days, these deposits can clog fuel lines, injectors and fuel filters. The results are startup problems, sluggish performance and even reduced engine life. By adding a gasoline stabilizer the fuel will remain fresh for up to 12 months and helps prevent gum and varnish build-up during months of storage. Fuel stabilizers can also help prevent corrosion and rust caused by accumulated condensation in the fuel system.

Learn more about how Grainger can help you keep your fleet maintained and ready for any weather here.

The information contained in this article is intended for general information purposes only and is based on information available as of the initial date of publication. No representation is made that the information or references are complete or remain current. This article is not a substitute for review of current applicable government regulations, industry standards, or other standards specific to your business and/or activities and should not be construed as legal advice or opinion. Readers with specific questions should refer to the applicable standards or consult with an attorney.