5 Necessary Skills for the 4th Industrial Revolution

By Grainger Editorial Staff 1/9/23

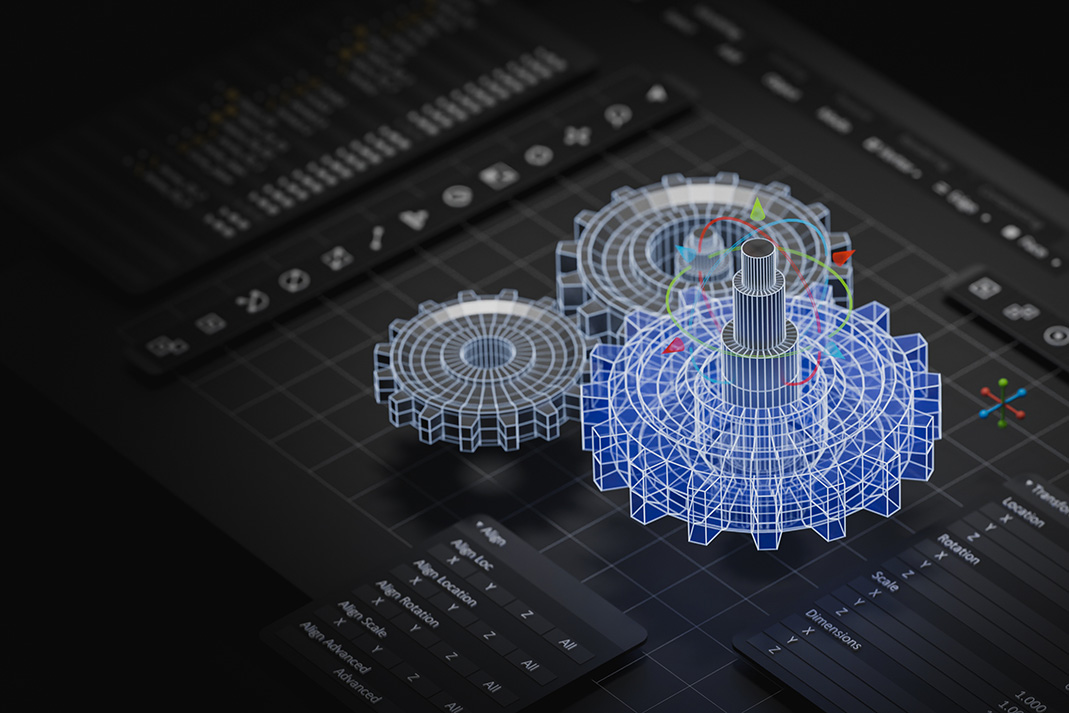

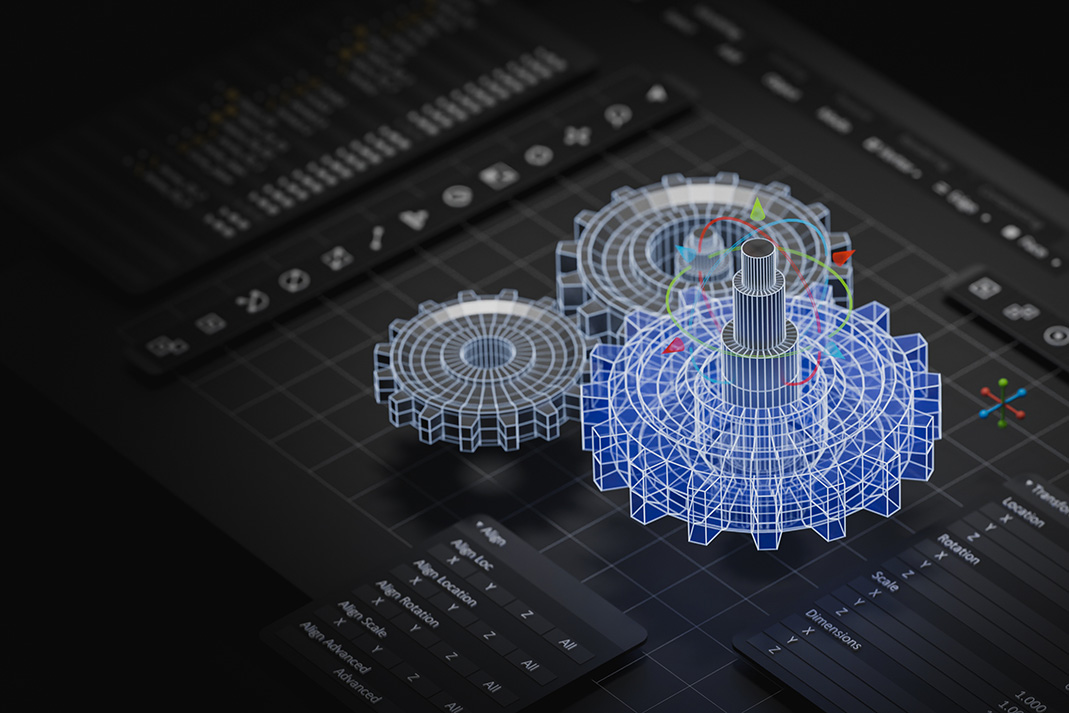

The world is entering a fourth industrial revolution as powerful computer networks transform manufacturing processes and reorient workers’ relationship to their trade. The rise of artificial intelligence (AI), the expansion of the Industrial Internet of Things (IoT), the emergence of immersive virtual reality (VR) and the addition of in-house additive manufacturing (3D printing) will impact almost every job on the production line.

Soon, AI-enabled industrial software may be able to make routine decisions across your entire plant. Armed with real-time data from thousands of IoT sensors spread throughout the facility, a smart system may soon coordinate and control every step of production, from ordering feedstock to loading finished goods onto trucks. Software will schedule predictive maintenance and assign shifts, and it may eventually be capable of optimizing the operation of every piece of machinery on the production floor.

As technology takes over more advanced tasks, human workers will need to adapt. An Oxford Economics Report estimates that automation could displace 20 million manufacturing workers worldwide by 2030. However, MIT researchers believe AI will also create jobs, leading to a highly productive manufacturing workforce of “superminds” as humans use their unique skills to complement the analytic power of computers.

Even the smartest production line will still rely on humans for guidance. Workers can prepare for the fourth industrial revolution by building five skill sets that the factories of the future will demand.

Five Human Skills to Cultivate Now

You may wonder about the role of human workers when AI is managing your operations. How can a plant manager contribute to a process that has already been perfected over thousands of virtual tests? Fortunately, AI will still need human operators to complement its strengths and fill in for its blind spots.

1. Exercising Human Judgment

The software may know everything about the production line, but it will have virtually no knowledge of the world outside your facility’s walls. Human workers will need to use their judgment to make the best decisions based on the AI’s data analysis.

For example, a smart paint robot may determine that slowing its spray arm will result in a more even coating. The AI might be able to inform an engineer that adding 30 seconds to every part’s time in the paint booth will reduce the variance in coating thickness by 20 percent. The software can make this prediction with great confidence, but a human engineer will need to decide whether adding time to the production process would add meaningful value to the final product.

The AI system will be able to nail the specifications you set for it, but it may lack the context of what your customers are looking for. Your plant engineer will need to guide the AI in creating high-quality products that stand apart from the competition.

Skills to leverage: Values-based judgment. You’ll never be able to compete with the AI in data analysis, so focus on understanding the intangibles. Human workers will need to translate values like build quality, attractive design and ergonomics into product specifications the AI can target.

2. Handling the Unexpected

As the past two years have demonstrated, industry sometimes has to find creative solutions to unexpected challenges. An AI system is less equipped to handle unprecedented situations for which it will have no prior data to guide it.

For example, during the shipping container shortage of 2021, manufacturers had to scramble to find alternative shipping methods. An AI system would probably not be capable of considering roll-on/roll-off or on-deck shipping, since the digital twin of your facility likely has no knowledge that these shipping methods exist. Humans who can handle novel disruptions will play a valuable role as software starts to guide routine operations.

Skills to leverage: Creative thinking and a broader knowledge of the world. The software may only understand business as usual, so it will be up to you to think outside the box during a crisis.

3. Providing the Human Touch

Software is also a long way from understanding human nature. The system may determine that 4:30 a.m. is the optimal time to start a production run, but it won’t appreciate the difficulty of staffing a predawn shift. Similarly, an AI system may schedule a maintenance worker to swap out a dozen high-voltage switches in one night, failing to understand the burden of wearing an arc blast hood for an entire shift. At some point, a human manager will need to review the system’s recommendations and decide whether the most efficient procedures are realistic.

Skills to leverage: Communication and teamwork skills. The AI’s recommendations may seem ruthlessly analytical. Human workers will need to provide these soft skills that keep teams running.

4. Embracing Lifelong Learning

The fourth industrial revolution will not happen all at once. As AI takes over routine operations, workers will need to upskill and take on new roles. This will require continuous education to learn new systems and operate new technological interfaces. Workers who are used to keying in commands at a control terminal may soon be controlling equipment through an immersive VR environment. To get the most out of new technologies, workers will need to embrace a lifelong learning.

Skills to leverage: Study skills, time management and a proactive approach to professional development. Workers who take the initiative to pursue new skills and knowledge will be able to stay ahead of technological developments.

5. Communicating Across Disciplines

Designing effective AI systems for production requires close collaboration among data scientists, process engineers and equipment operators. Computer programmers with the skills to build machine learning algorithms may lack an understanding of actual production machinery, and vice-versa. To create an AI system that can solve industrial problems, software engineers will depend on insights from experienced production workers. Their knowledge will help interpret the data streaming in from the facility’s IoT sensors, turning statistical noise into meaningful patterns. Workers will need strong communication skills to help the AI understand what’s happening on the production floor.

Skills to leverage: Communication and teamwork. Operating an AI factory will be a team effort, drawing on workers with diverse knowledge bases. The ability to explain technical processes to colleagues from different backgrounds will be vital.

The information contained in this article is intended for general information purposes only and is based on information available as of the initial date of publication. No representation is made that the information or references are complete or remain current. This article is not a substitute for review of current applicable government regulations, industry standards, or other standards specific to your business and/or activities and should not be construed as legal advice or opinion. Readers with specific questions should refer to the applicable standards or consult with an attorney.