Safety Management

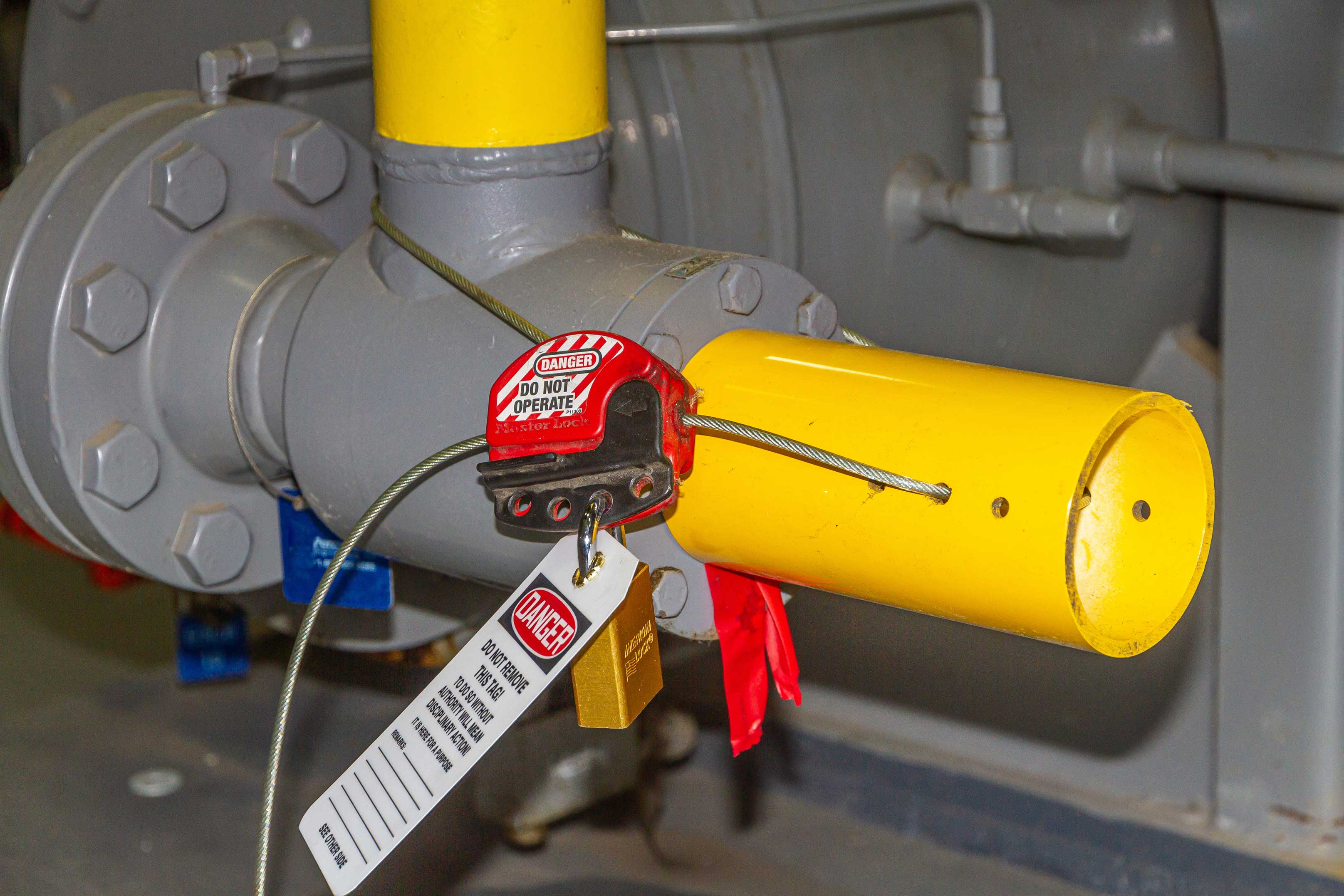

OSHA Top 10 Violations: 2025

OSHA's annual list of most-cited standards offers valuable guidance on where companies might focus their safety compliance efforts.

10/13/25

Safety Management

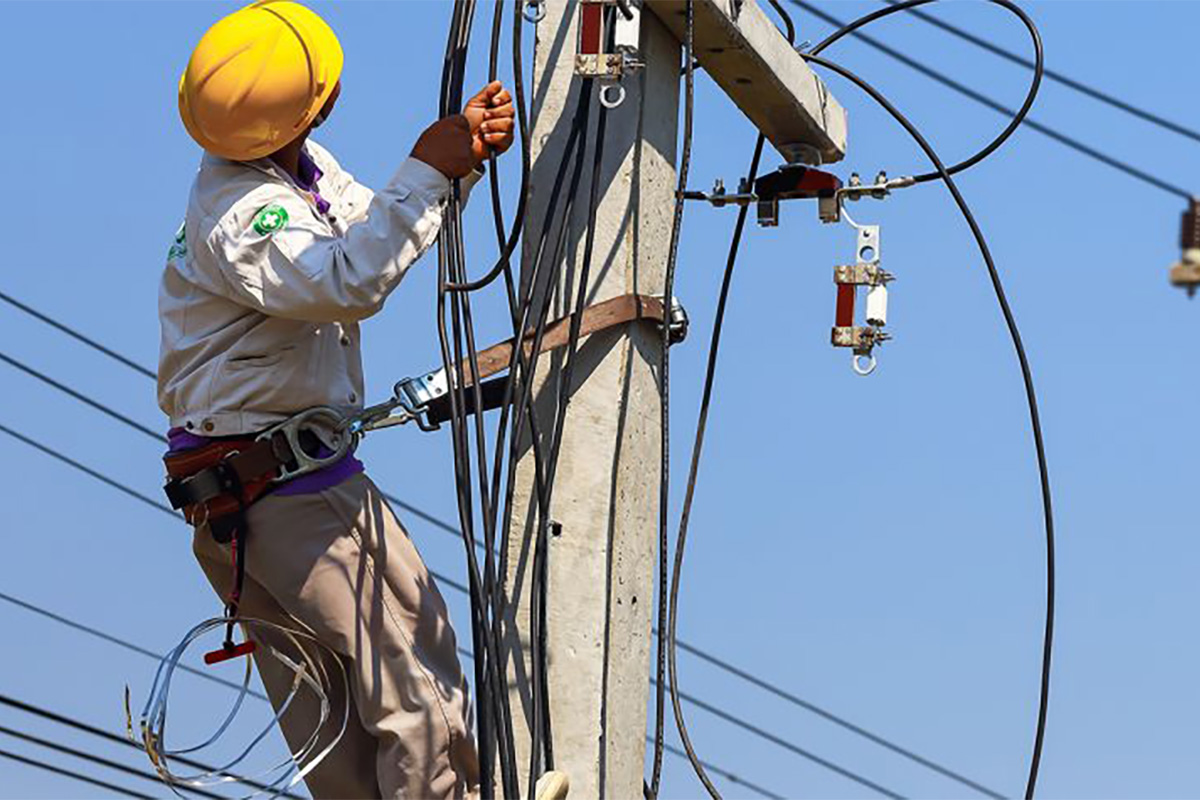

How to Avoid 7 Common Electrical Hazards at Work

Workers are often unaware of the potential electrical hazards in their work environment, putting them at risk for electrocution. Learn how to avoid 7 common electrical hazards at work.

09/05/25

Safety Management

5 Strategies to Reduce Noise in the Workplace

22 million workers are exposed to occupational noise hazards in their jobs today, and one-third of workers who have a history of occupational noise exposure show measurable hearing damage.

08/18/25

Safety Management

Abrasive Safety: Understanding the Hazards

Read about the hazards of working with abrasives and get some guidance on how to prevent injuries.

05/30/24