How Additive Manufacturing Stands Up Against Traditional Machining

By Grainger Editorial Staff 5/5/22

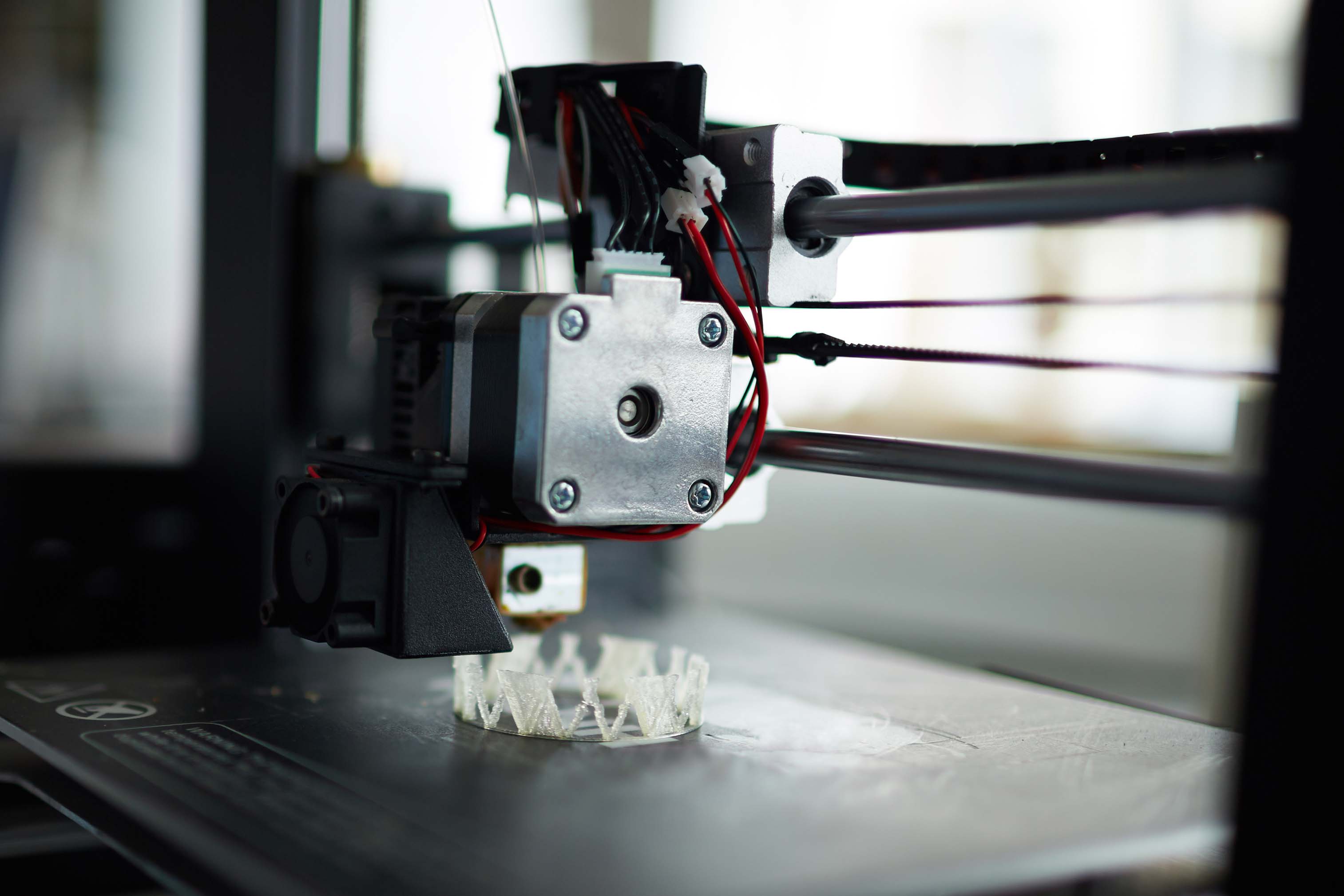

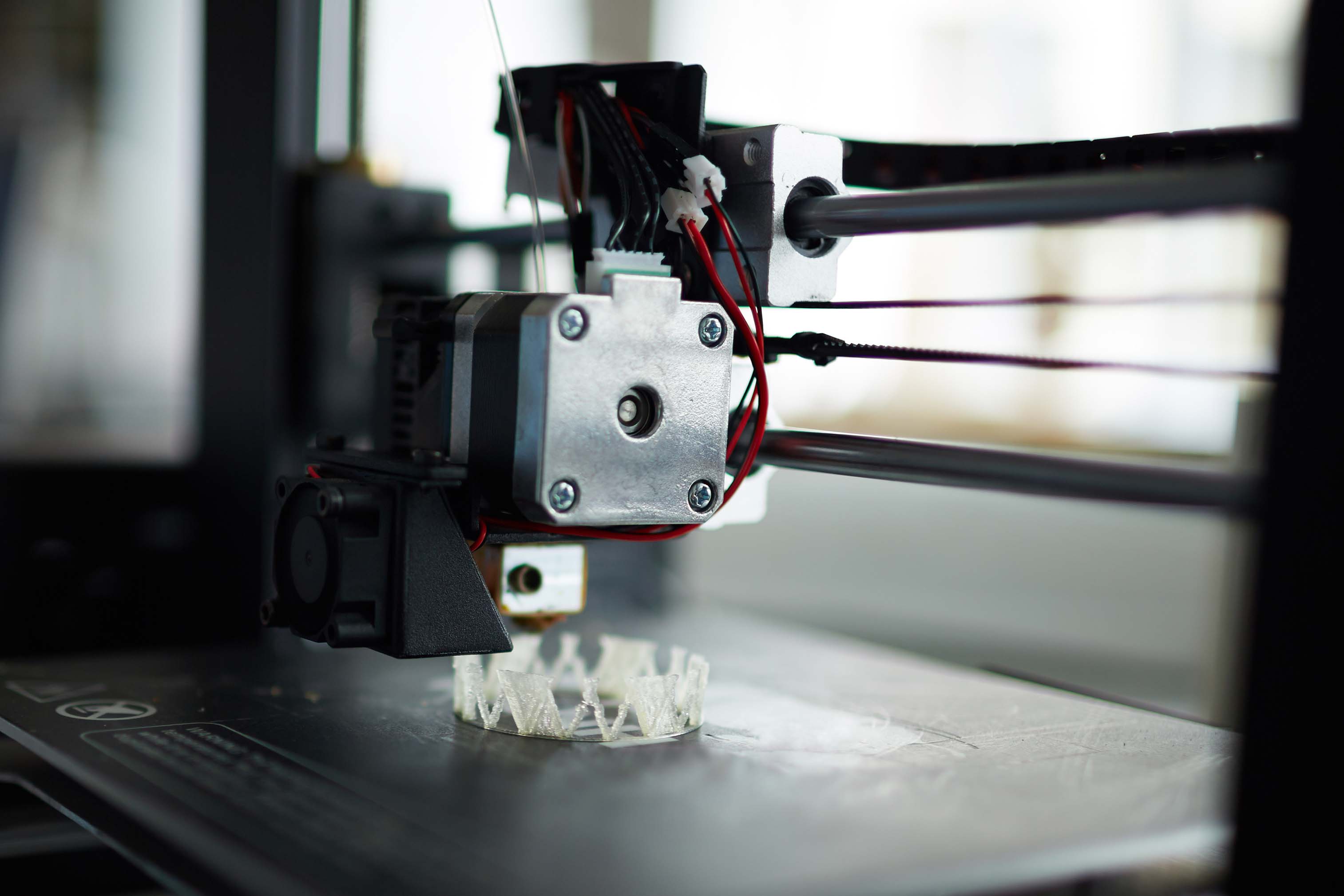

Additive manufacturing is making inroads in the metalworking industry. The overall global additive manufacturing market is projected to triple from 2020-26, to more than $37 billion, according to a study referenced by Industry Today. Machine shops continue to evolve in how they use 3D printing technology in additive manufacturing, though traditional CNC machining – think of it as subtractive manufacturing – still has a solid footing. Electing one or the other depends on a number of different factors.

When to Consider Additive Manufacturing

Complex pieces: The greatest advantage of additive manufacturing is that components with complex internal geometry can be manufactured with relative ease. There are no tool heads to swap out, the component never needs to be rotated or repositioned, and the printer does not need clearance to work on internal faces.

Metal Additive Manufacturing Magazine reports that 3D printing can produce components with a complex cross-section that would be impossible to make from a single piece with CNC tooling. For example, a 3D printer can produce internal cavities of any shape, regardless of the size of the aperture on the outside of the component.

Rapid prototyping: The second big advantage of 3D printing is that a component’s design can be refined without requiring retooling. According to California Manufacturing Technology Consulting, this makes additive manufacturing ideal for iterative prototyping. A prototype component can be printed and tested, leading to refinements in the prototype’s design that can then be printed and retested with minimal turnaround time and tooling costs.

Customization: The ability to easily make customized components also makes additive manufacturing a natural fit for medical and dental implants. Medical Product Outsourcing Magazine reports that dental labs are using 3D printers to produce bridges and crowns that are perfectly fitted to a volumetric scan of the patient’s mouth. Since no two implants are the same, the ability to print an implant without programming tool paths can reduce costs and production time.

Using titanium: Titanium is prized by the automotive and aerospace industries for its light weight and high strength. However, working titanium with CNC mills is a notoriously painstaking and expensive process. According to Modern Machine Shop Magazine, titanium’s poor conductivity can concentrate heat along the cutting face, overheating the tool head. Additionally, the high cost of titanium stock means that subtractive manufacturing methods often produce an expensive pile of shavings on the shop floor.

Additive manufacturing avoids these issues. According to All3DP Magazine, titanium has become the most common metal for commercial 3D printing applications. Since printers use lasers or electron beams to weld titanium powder in place, there is no tool head to overheat. Manufacturing software firm AMFG reports that additive manufacturing can cut titanium material waste by half, reducing raw material costs. And the printer’s ability to create internal latticework can further reduce a component’s weight, taking full advantage of titanium’s extraordinary tensile strength.

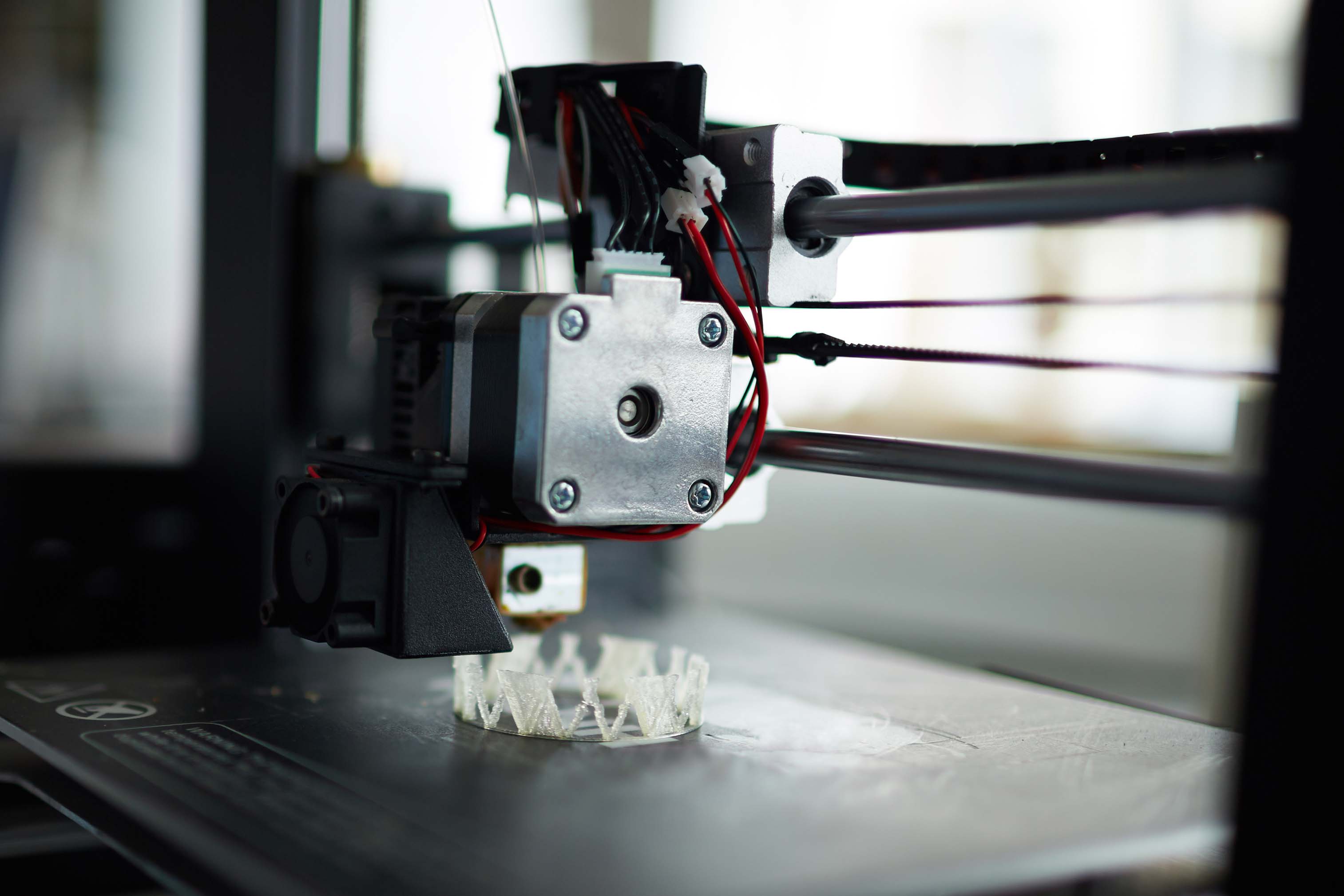

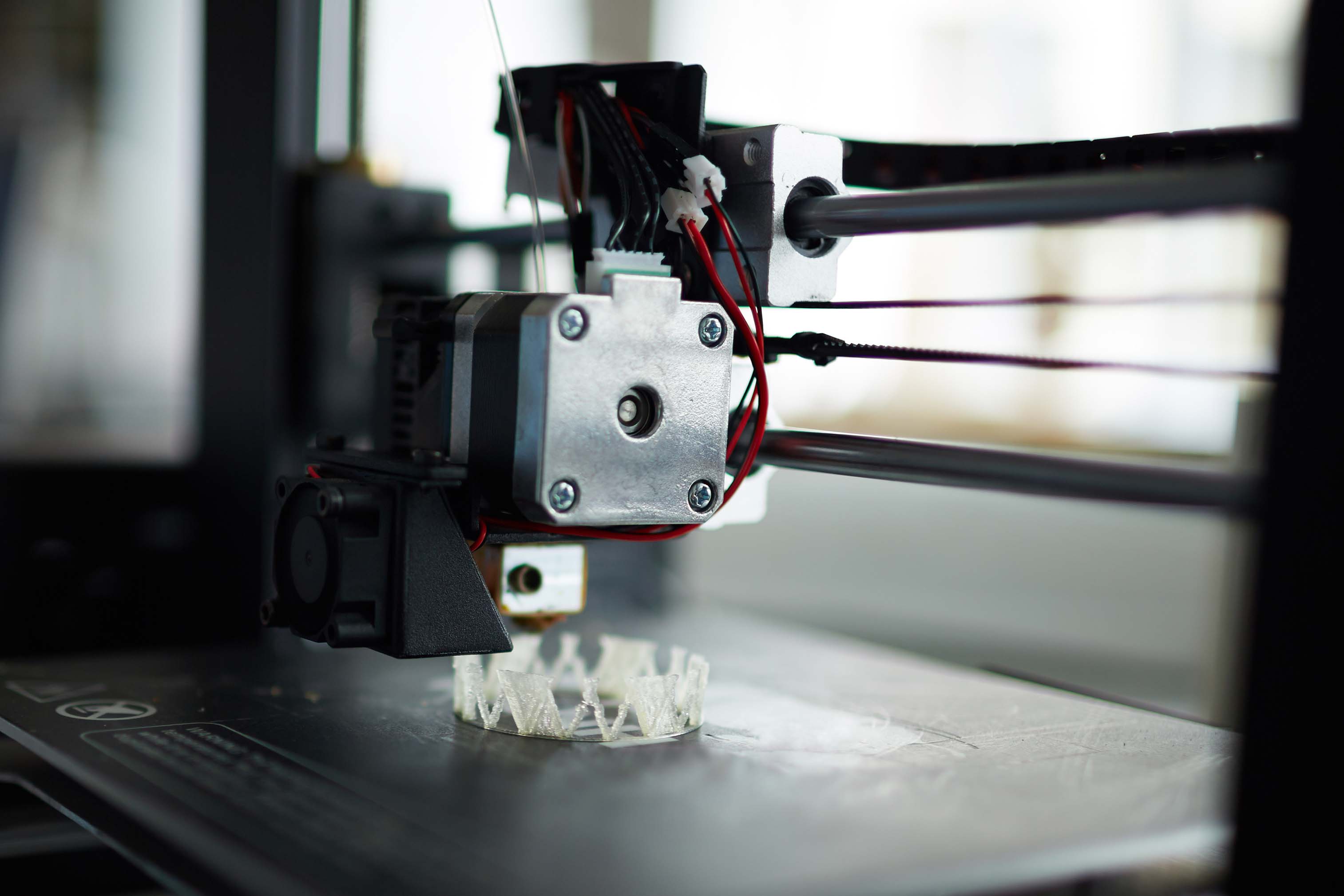

When to Consider CNC Machining

Need for speed: Additive manufacturing enjoys an initial speed advantage over traditional machining, since it requires little setup or programming time. But once a tool path has been set up, CNC machining is far speedier. The prototype manufacturing broker Hubs estimates that for components with machinable geometry, traditional methods are faster and cheaper for production runs of 10 or more identical parts.

Need for size: A 3D printer cannot produce parts larger than its build chamber. For most commercial metal printers, 3D Natives Magazine reports that the build chamber is between 8 and 12 inches on each side, whereas CNC mills commonly have travels in the 24- to 36-inch range.

Variety of materials: Additive manufacturing is restricted to metals that can be selectively deposited from a fine powder or thin wire stock. 3D Natives Magazine reports that additive manufacturing is restricted to metals that can be refined into a consistent powder with low water absorption that will not oxidize under the high temperatures of laser deposition. This limits the variety of alloys available for printing, compared to traditional machining.

Need for precision: According to 3D Natives Magazine, the laser deposition method used in most metal 3D printing is less precise than CNC cutting tools. Precision tolerances in CNC machining are measured to the hundredths of a millimeter, compared to tenths of a millimeter for 3D printing. This also results in a matte finish for components, rather than the smooth polished look of machined metals.

What About Quality?

Components printed through laser deposition are essentially composed of thousands of microscopic laser welds. A Department of Energy study found that 3D-printed components can suffer many of the same issues as welded metals, including porosity, delamination, cracking and swelling. For printed steels, the metal’s grain structure can change during deposition, changing its structural characteristics.

However, issues affecting metal quality can be overcome. According to Endagaget, the Federal Aviation Administration has certified 3D printed components for structural use in commercial airliners after conducting rigorous stress tests. The Society of Manufacturing Engineers reports that a new generation of printers that operate under a vacuum can greatly reduce imperfections in the metal’s structure.

Safety Management

Understanding Sorbents: Choosing the Right Spill Control Supplies

Understand how sorbents work, how different spill kits are used and how to choose the right spill control supplies to help support safer cleanup and compliance.

![]() OUR LATEST KNOWHOW

OUR LATEST KNOWHOW

Building Maintenance

Wet Mopping vs. Dry Mopping: What’s the Difference?

When used correctly and in the right setting, wet and dry mops both offer different benefits. Learn how to use a wet or dry mop to properly clean and maintain your flooring.

The information contained in this article is intended for general information purposes only and is based on information available as of the initial date of publication. No representation is made that the information or references are complete or remain current. This article is not a substitute for review of current applicable government regulations, industry standards, or other standards specific to your business and/or activities and should not be construed as legal advice or opinion. Readers with specific questions should refer to the applicable standards or consult with an attorney.