KNOW BUILDING MAINTENANCE

Learn some strategies here for reducing facility energy costs and getting the most out of HVAC, lighting, and electrical systems. Get tips and checklists for predictive and preventive maintenance, and see how others are tackling such challenges as managing aging building systems and assets.

Building Maintenance

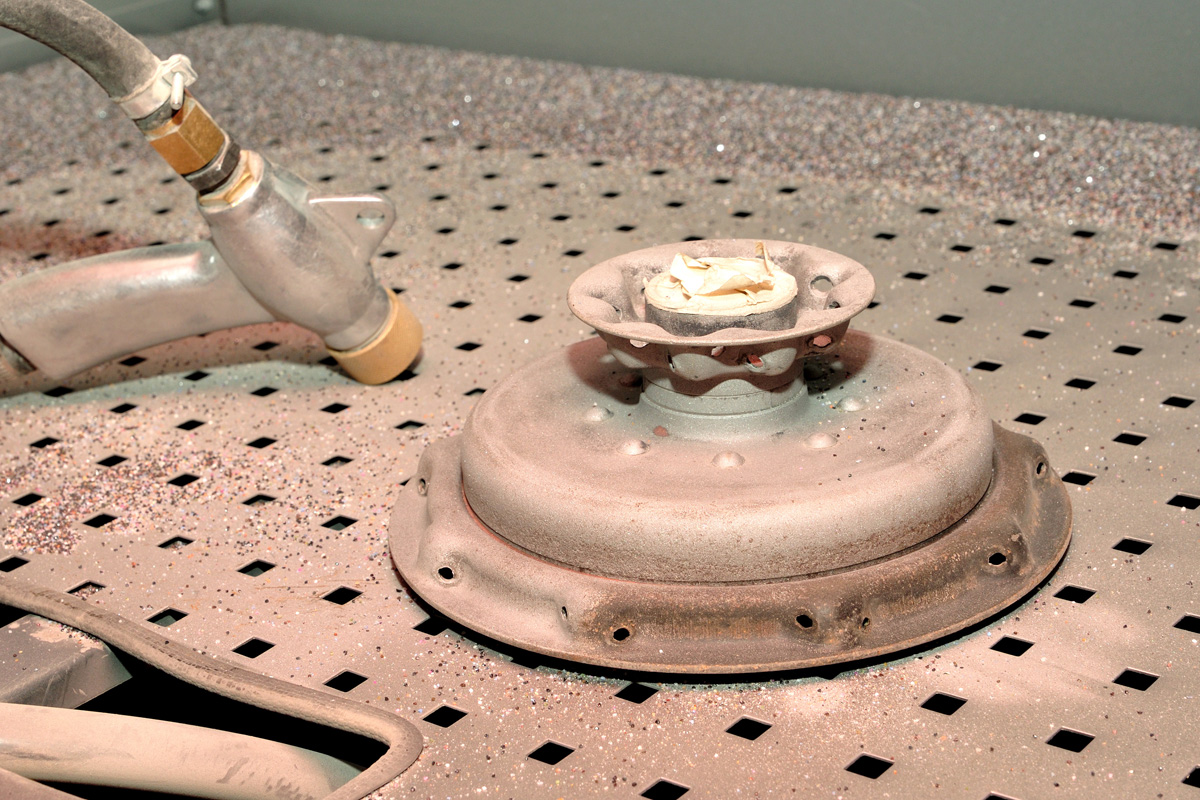

How to Clean and Remove Concrete Stains

Whether cleaning a concrete driveway or tackling stains in a garage, using the right cleaning supplies can help concrete look its best.

10/01/25

Building Maintenance

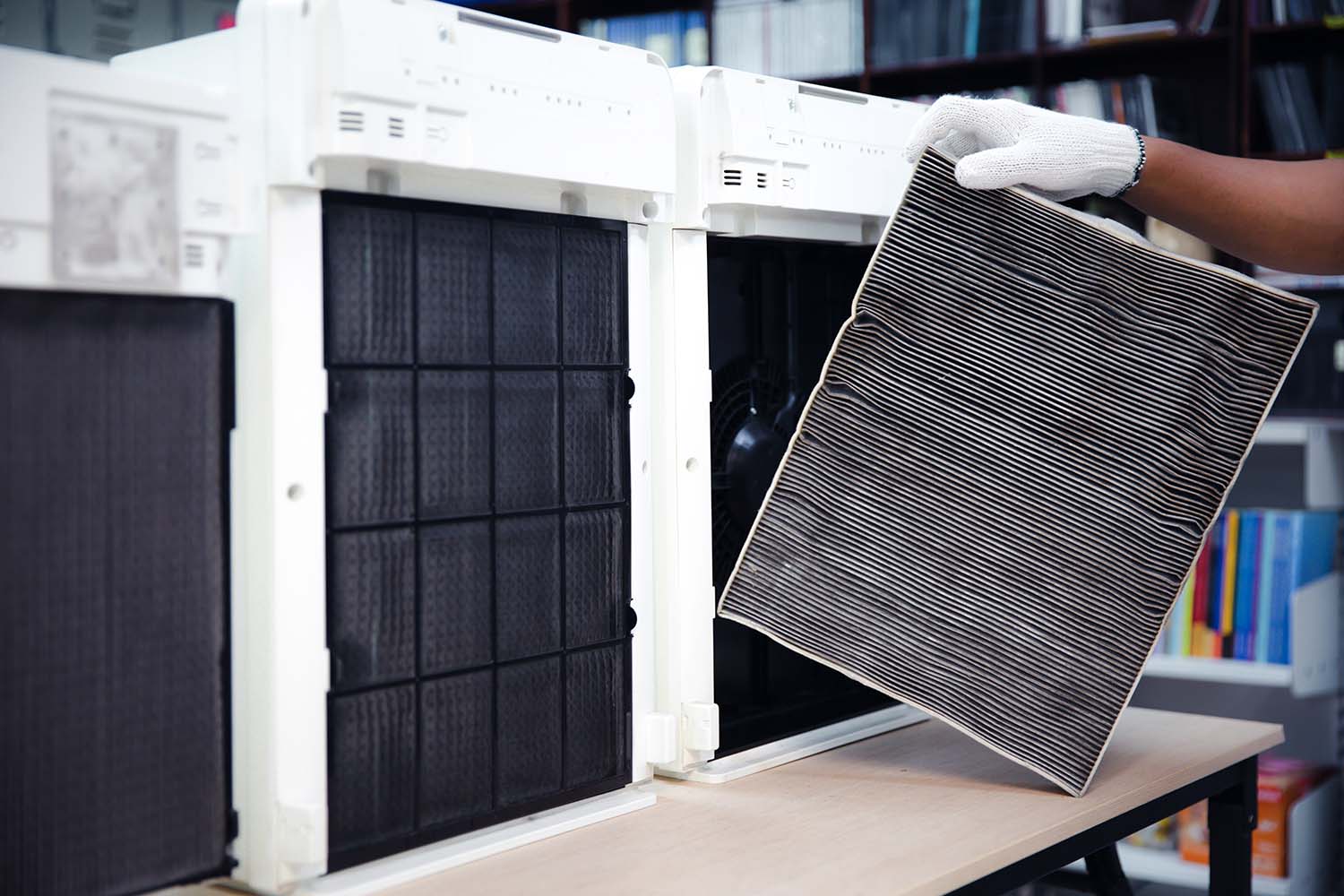

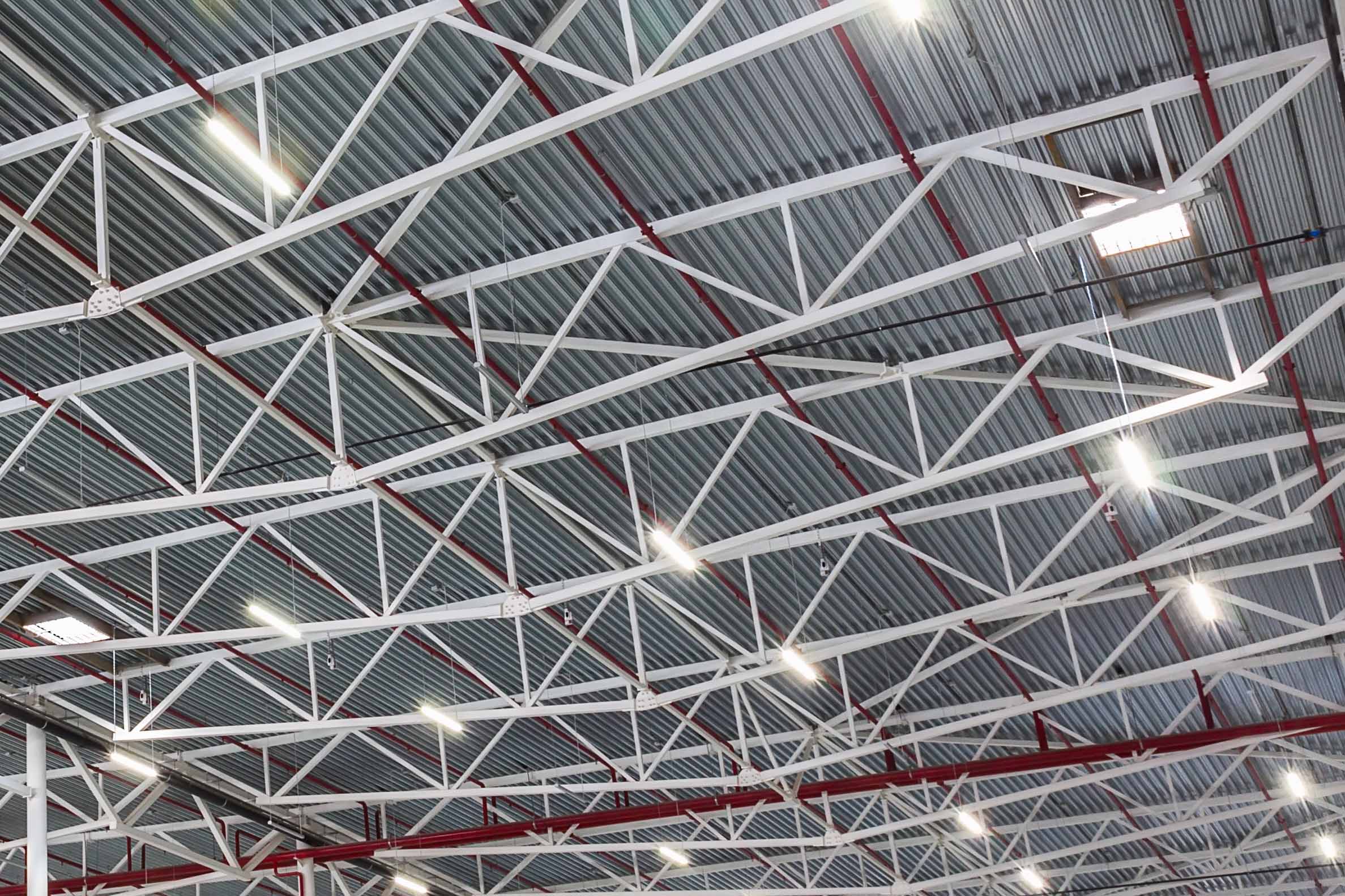

Four Key Questions About Zoned HVAC

How can building managers make sure HVAC systems deliver the right temperatures and ventilation to different areas of a building serving different purposes?

09/23/25

Building Maintenance

Integrated Pest Management: Preventing Rodent Infestations in Your Facility

Learn how an integrated pest management plan can help prevent rodent infestations in facilities and quickly resolve issues when they arise.

09/18/25

Building Maintenance

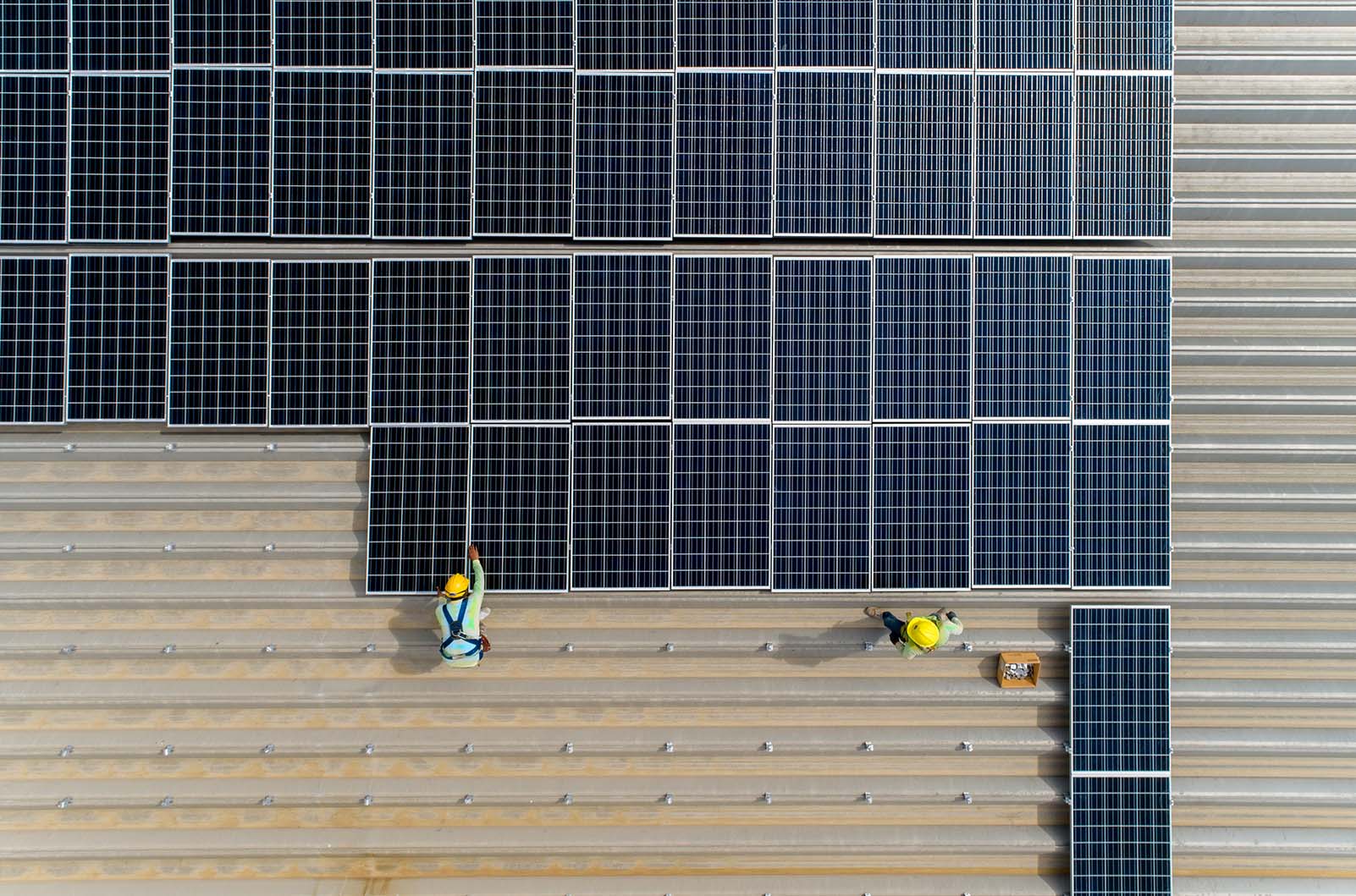

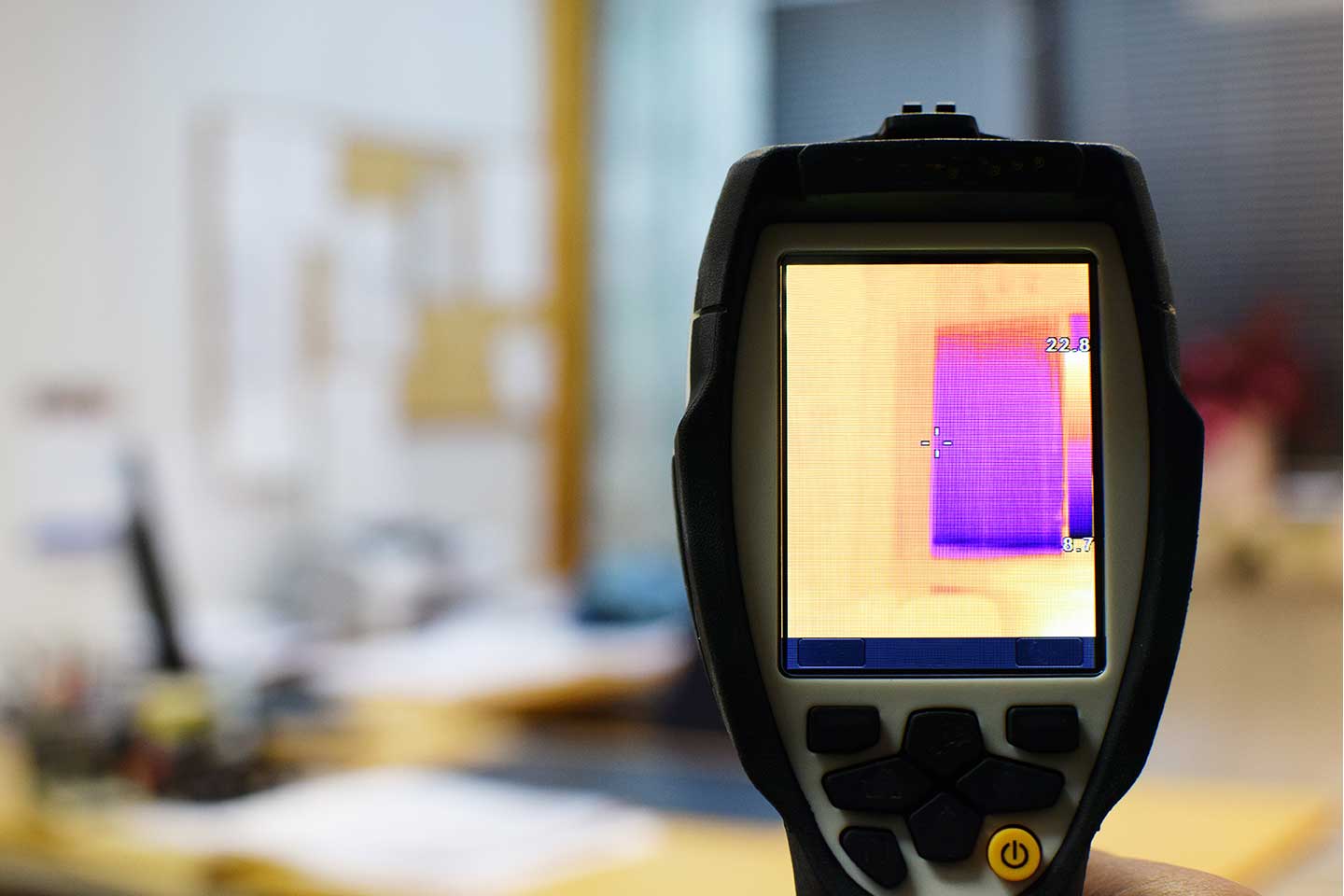

Thermal Imaging for Preventive and Predictive Maintenance

Learn more about how thermal imaging cameras work and can help identify potential problems before they become costly issues.

09/13/25