How It's Done:

NEON SIGNS

This is the Stuff They Use to Brew the Beer

By Grainger Editorial Staff 6/13/22

If you want to stay in business, you've got to make the best product you can. That's what Kevin Baldus believes, and as a co-founder of a thriving craft brewery, he should know. With co-founders Charles St. Clair and Alex Stankus, he's producing beers to be proud of at Black Horizon Brewing.

He says that to make the best beer, you start with the best stuff—the best water, the best hops, the best malt and the best equipment. This is the stuff they use to brew the beer.

This interview has been edited for clarity.

The Recipe

The brewing process starts with four things: water, yeast, hops and malt. With different combinations, you can make whatever style of beer you want. It's a recipe, just like you'd have for cookies or bread.

When you formulate your recipe, you're thinking about what can give you characteristics you want in the beer. How bitter do you want it? How do you want the aromatics to come through? And what do you want to play with?

The Water

The most important thing is the water. Our water is sourced from Lake Michigan. I'm biased, so I think it's the best water in the world. Every brewer that's using Lake Michigan water will tell you that it's the best water in the country, and that's why our beer in Chicagoland is so good.

The Mash Tun

The mash tun is where the brewing starts. The mashing process converts starch into sugar. The more malt you add, the more sugars it makes.

It steeps together at a controlled temperature for a specific time to get maximum fermentability. After the starch is converted, the mixture is called "wort"—sugar water, basically.

The Boil Kettle

The wort goes to a boil kettle. We keep our two-barrel boil kettle around as a sentimental piece of equipment—we started as a two-barrel, all-electric system. But now we've gone all the way to an eight-barrel boil kettle.

At the start of the boil, you add hops to impart bitterness. The more hops you add and the longer it all boils, the more bitterness it imparts. That's where you get the back-end bitterness of an IPA. When you add hops at the end of the boil, or even after the boil, you can get a good waft of the aromatics, like stone fruit or citrus, depending on the hops you use.

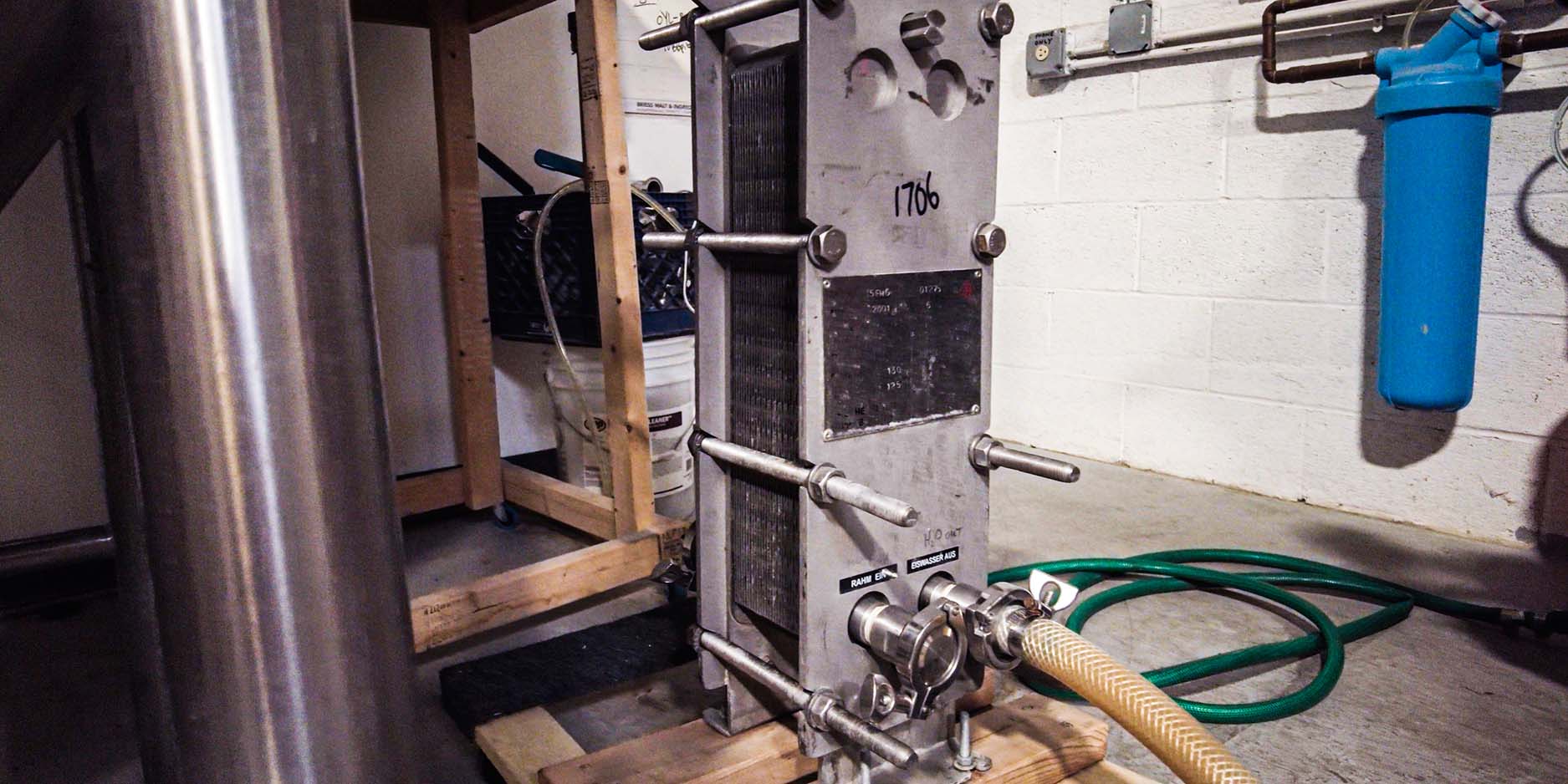

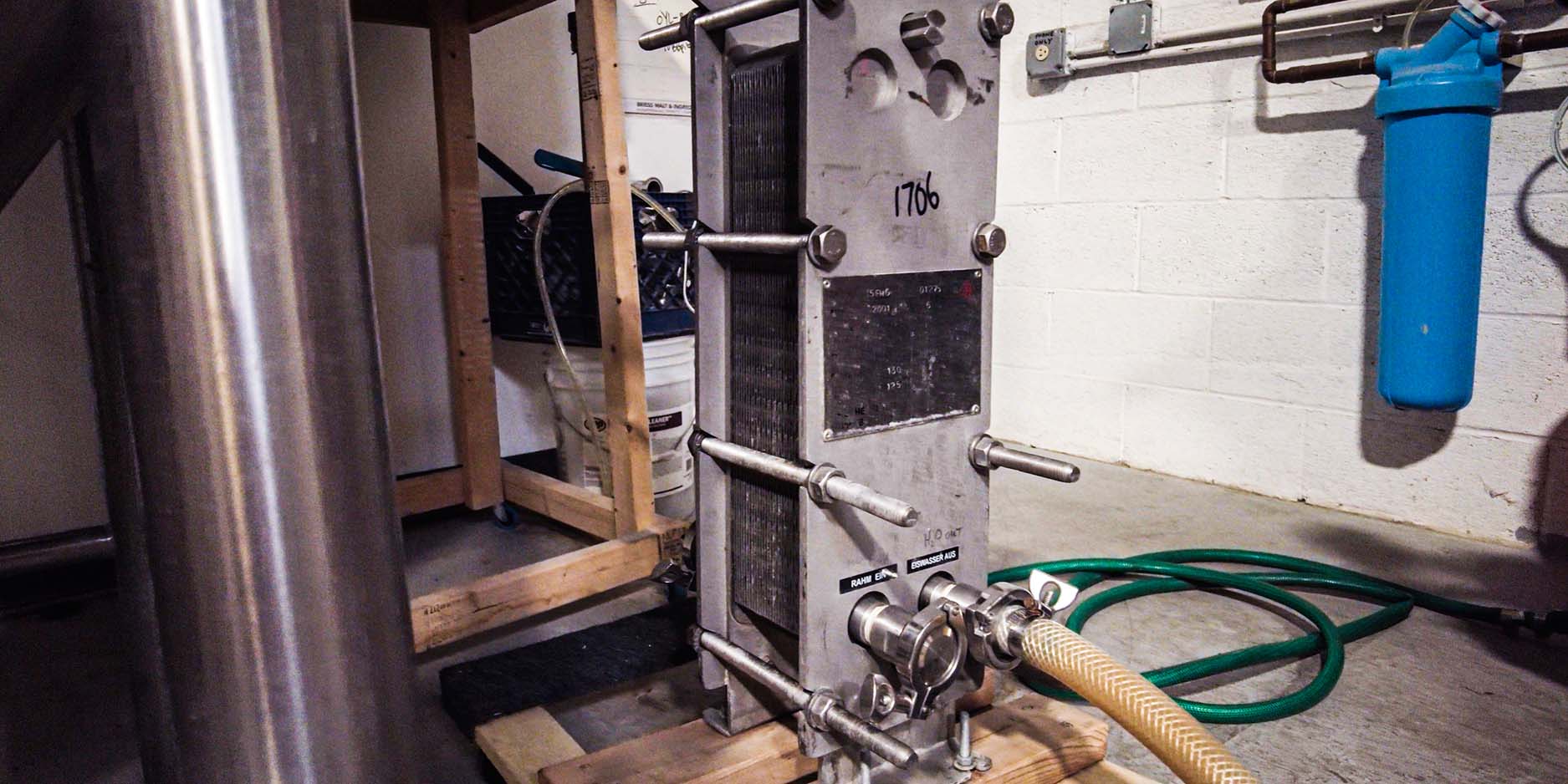

The Chiller

We pump the wort from the boil kettle through a chiller, which acts like the radiator in a car. Cold water passes through one side and the wort passes the other way, cooled to whatever temperature you want. It might be 60, 70 or even 80 degrees, depending on the kind of beer you're making.

You need to bring down the temperature before you dump the yeast into it. Yeast is a live animal, and if you put yeast into wort that's too hot, it dies.

The Fermenter

After you pitch the yeast, it starts eating the sugars in the wort. This happens in the fermenter. You have to control the temperature. All those yeast strains we use have different temperature ranges. Different styles of beer require different fermentation temperatures.

Fermentation gives off carbon dioxide, which escapes through the blow-off arm on the side of the fermenter. And it creates the alcohol for the beer. It might take about a week for something like a pale ale.

We started with a five-barrel fermenter. We were so proud when we got this stainless steel—it was our big boy. But it's one of the smaller ones we have now.

The Bright Tank

After the fermenter, we run it into a bright tank, where we cold-crash it down to a low temperature. The yeast that was suspended in the wort settles out, and we pump it off or save it for the next batch. This is where the beer is carbonated with a carb stone.

Then you have the finished product, ready to go. If we do an eight-barrel batch, we'd get about 165 gallons. We can keep it in-house on tap or can it for sale.

The Clean

A brewery seems glamorous, but the grunt work is where the quality comes from. Like the clean after you make a beer and all the mulch has been taken out—cleaning all the vessels, the fermenters, the bright tanks.

Everything gets cleaned and sanitized every time we use it because we can't have one bad bug in there. One bacterium could come in there and wreck 365 gallons of beer. If you can't clean, the beer's never going to finish out the way you want it. You've got to be vigilant.

We're not going to serve off-flavor beer. We don't like it. It won't pass our quality checks. Our beer represents us, so we've got to have top-notch stuff. If you want to stay in business, you've got to make the best product you can. No shortcuts.

The information contained in this article is intended for general information purposes only and is based on information available as of the initial date of publication. No representation is made that the information or references are complete or remain current. This article is not a substitute for review of current applicable government regulations, industry standards, or other standards specific to your business and/or activities and should not be construed as legal advice or opinion. Readers with specific questions should refer to the applicable standards or consult with an attorney.