How It's Done:

BUILDING UTILITY TERRAIN VEHICLES

How It's Done: Building Utility Terrain Vehicles

By Grainger Editorial Staff 6/21/24

Utility Terrain Vehicles, or UTVs, have grown in popularity thanks to their agility and versatility. They're often used to haul equipment and supplies to areas larger vehicles can’t access. UTVs are seen anywhere from farms to baseball fields to residential neighborhoods. Outdoor enthusiasts use them for hunting, and their sturdy frames make them great for towing. Most UTVs have a large payload and many feature an enclosed cabin with seating for up to four passengers.

UTV manufacturer Landmaster began in Louisiana in 1967 under a different name manufacturing go-carts. In the late 1990s, the company expanded into building UTVs. The company moved its operations to Columbia City, Indiana, in 2017.

Plant Manager Brian Moloney explained Landmaster's assembly process and how the assembly line is set up to handle any model type of UTV in any custom configuration. Every 36 minutes a vehicle rolls off its assembly line, which requires 12 operators from start to finish. Brian walked through the steps of building a UTV.

1. Fabrication and Bending the Frame

Landmaster does its own fabrication and circular tube bending. Each bender is automated so the operator simply chooses a part number, and the machine will bend every angle needed as well as punch all the mounting hardware holes needed for that part.

2. Welding the Frame

At this stage, the pre-formed bended sub-assemblies are welded together to build the frame front to back and bottom to top, including the overheads needed for the roofs. Once the frames are welded, the team does a full inspection check of every weld to make sure everything is intact and there aren’t any welds missing.

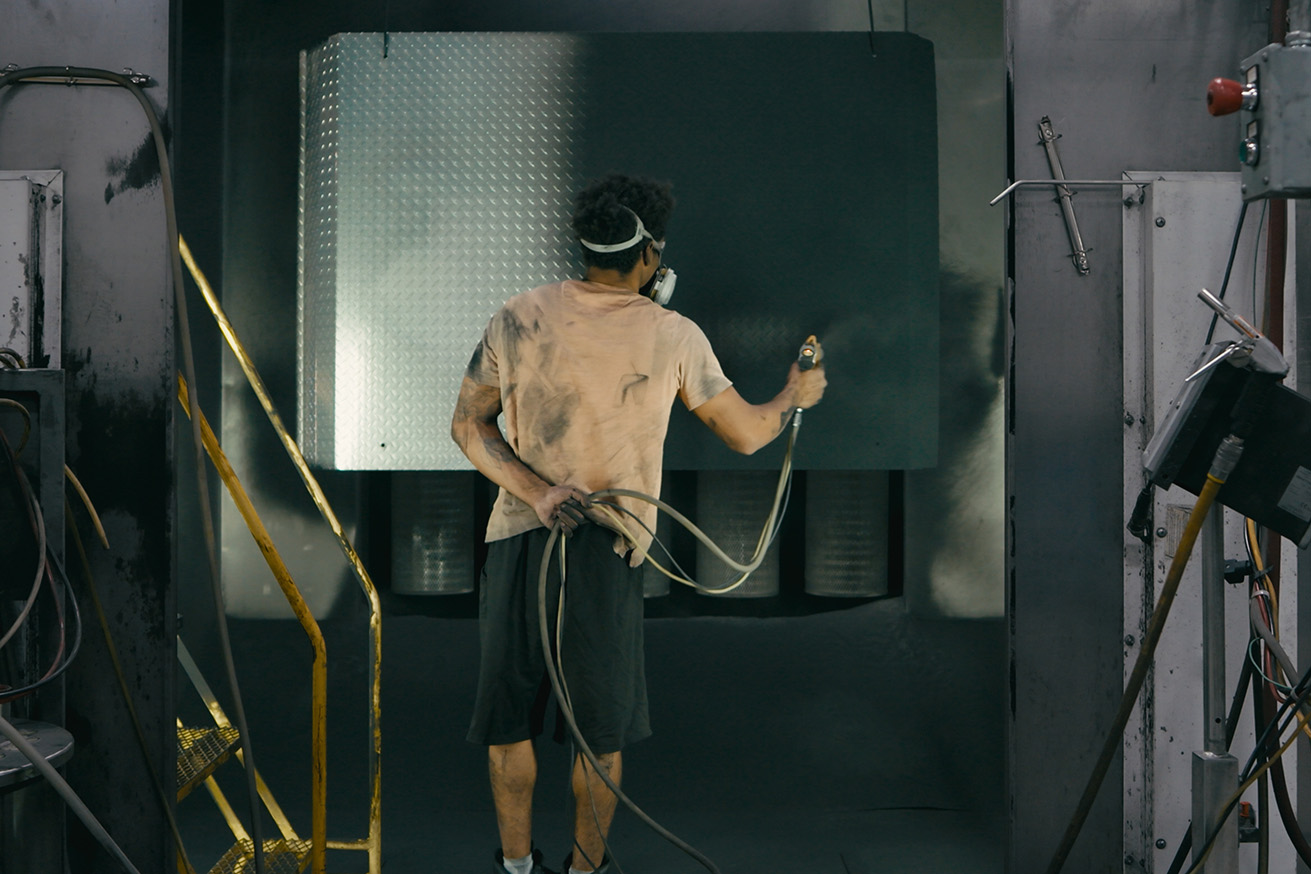

3. Powder Coating

Powder coating helps protect the chassis from rust in inclement weather. The five-stage cleaning process includes a rinse cycle, then an alkaline bath, another rinse cycle, a zirconium bath and a final rinse cycle. This part of the process prepares the metal by charging it so the powder coating will stick. After that, the frame will go through a full bake to ensure it’s completely dry and ready to powder coat. Once sprayed with the paint coating, the assembly goes to a 400-degree oven to be baked for about an hour. After the bake, it goes through a cool-down cycle before the frame is ready for production.

4. Assembling the UTV

Here the raw frame is assembled one piece at a time. This includes the beginning stages of building the transmission, setting up the brakes, adding the tires, assembling the suspension and placing the engine. This stage also includes installing the dashboard, which is customized depending on the accessories chosen by the customer.

5. Quality Control

At this stage, the unit is run to make sure it’s fully functional. The unit’s electrical system, brakes and parking brake are tested. The vehicle’s alignment is checked, and any specific configurations the customer has ordered are also tested.

6. Final Assembly

This is the final stage where any custom accessory options like stereo speakers, the roof or special configurations for the hood, turn signals, bumpers or headlights are added. The team also does an alignment check, and a "dyno check" with a dynamometer, where the unit is run at idle and at full RPM to make sure it operates as expected.

Read more stories about people getting the job done here.

The information contained in this article is intended for general information purposes only and is based on information available as of the initial date of publication. No representation is made that the information or references are complete or remain current. This article is not a substitute for review of current applicable government regulations, industry standards, or other standards specific to your business and/or activities and should not be construed as legal advice or opinion. Readers with specific questions should refer to the applicable standards or consult with an attorney.