Solutions for Tracking Misplaced or Stolen Tools

By Grainger Editorial Staff 5/23/23

Critical assets like tools and equipment can be costly to replace when lost or stolen. A 2016 report by the National Equipment Register (NER) estimated the cost of tool and equipment theft in the U.S. varies from $300 million to $1 billion annually. Builder Magazine highlighted the continued challenges construction managers faced throughout the COVID-19 pandemic with tool, equipment and material theft. Several factors contribute to tool theft, including easy access to tools and equipment, lack of accountability and poor security. Learn simple and effective ways you can help protect your tools and equipment from being lost or stolen.

Traditional Tool Tracking

Using logbooks and spreadsheets is one of the most common methods to manually track tools and equipment. Logbooks can help workers record when a tool or piece of equipment is checked out and returned. Spreadsheets can also be used to develop a tool and equipment inventory, including an item’s status and location.

Although this type of inventory tracking can be time-consuming, it’s widely used due to its low cost and simplicity. However, this type of tool and equipment tracking can be prone to errors and inaccuracies since workers could forget to update the sheet or misplace the tool altogether.

Modern Tool Tracking and Asset Tagging

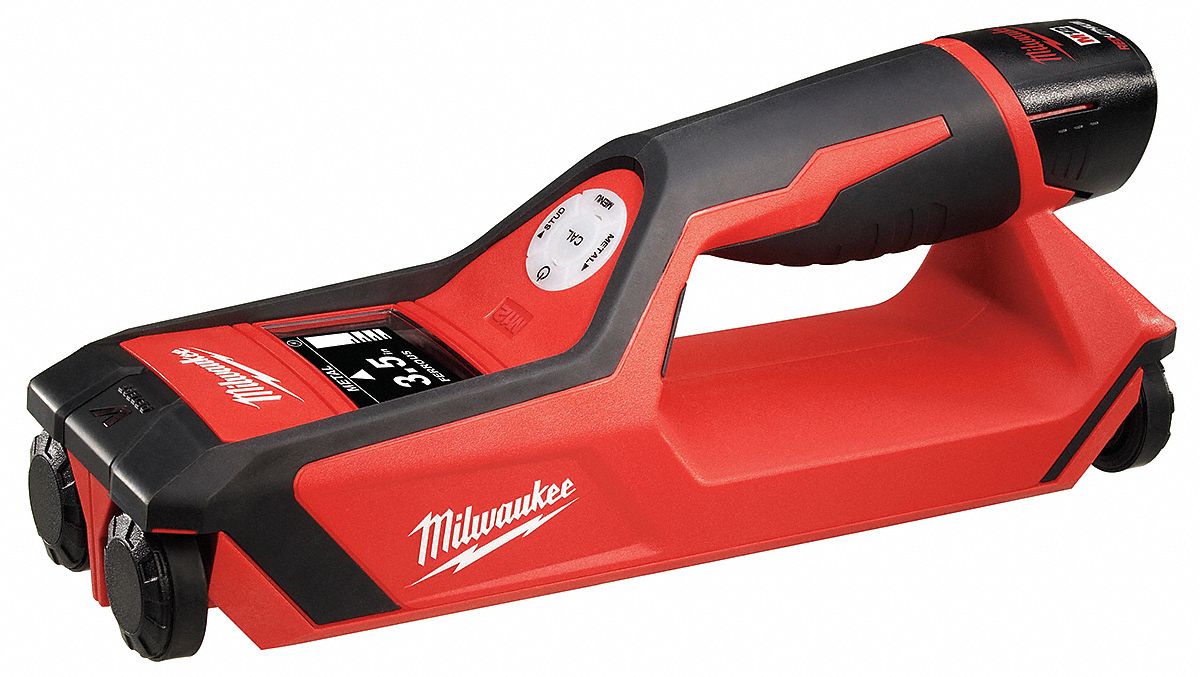

Many companies are turning to technology like Radio Frequency Identification (RFID) to help offset the limitations of traditional tracking methods. RFID uses small tool and equipment tags with a unique identifier that can be scanned by an RFID reader. This automated tracking provides more accurate and up-to-date information about the status of tools or equipment.

Asset tagging is a common tool-tracking method that involves attaching a physical tag to a tool or piece of equipment. There are several types of asset tags made of different metals and tamper-proof labels that can be attached to indoor and outdoor tools and equipment. Asset tracking tags contain a unique identifier, like a serial number or RFID tags, that can be read by a scanner and monitored by a digital tracking system to provide real-time information about the location and status of tools and equipment. Asset tagging helps quickly identify, manage and track a variety of critical assets, from power tools and equipment to vehicles throughout multiple jobsites.

Other new tool-tracking methods include GPS tags and Bluetooth beacons that can be attached to tools and larger equipment like bulldozers or generators to help track their location. Users can create custom alerts and set up geofencing in a connected app to notify them if a tool leaves the jobsite or a certain area.

In addition to tracking and asset tagging, there are also smart tools available, that offer the ability to remotely lock tools or report them as missing. Smart tools use apps that allow users to add their tools to a cloud-based inventory management system. Many smart tools also offer a tool lock out security feature that makes a tool inoperable if it is stolen.

Tips to Prevent Tool and Equipment Theft

While tracking tools can help managers improve inventory management, it is also important to prevent lost and stolen tools and equipment in the first place. Maintaining an accurate inventory of tools and equipment, including the year, manufacturer and serial number, can help prevent loss and theft. Taking photos can also help maintain an accurate snapshot of the condition and location of equipment. Here are some additional strategies to help secure valuable tools and equipment:

- Use physical barriers like fences to limit access to job sites.

- Secure tools and equipment with padlocks or other types of locks.

- Keep valuable tools and equipment in wire cages or lockers to control access.

- Install exterior lighting and security cameras to monitor job sites and deter theft.

- Consider tool kitting or grouping a set of frequently used tools into one kit that can be easily tracked.

- Engrave, stamp or label tools and equipment with company logos or other identifying marks or serial numbers.

- Implement a tool-tracking system and educate workers on theft prevention.

Creating a Culture of Accountability

Consider conducting a risk assessment to help identify threats and gaps in security measures. In addition to using tracking technology, businesses can implement several strategies to help prevent stolen tools and equipment, including written policy that clearly states the consequences of employee theft. Training employees on how to prevent tool and equipment theft from the outside is also critical. Training can include how to secure tools and equipment, tips for identifying suspicious activity, and the actions to take if a tool or piece of equipment is stolen.

There are several ways to track tools, and the best solution for your business depends on many factors. While traditional tracking methods like logbooks and spreadsheets are still widely used, modern technology like RFID and asset tagging can provide more accurate and efficient tracking. Tool tracking combined with an asset management system can make critical equipment and tools easier to identify and help quickly locate lost or stolen items.

PPE in the Workplace

Safety Essentials: Protecting Employees and Supporting Compliance

Learn how the right safety supplies and processes can help support compliance, reduce injuries and protect employees throughout the workday.

![]() OUR LATEST KNOWHOW

OUR LATEST KNOWHOW

Equipment

How to Choose the Right Ceiling Tiles

Ceiling tiles are made of different materials to serve a variety of purposes, so make sure you're choosing the right kind of ceiling tile for your facility.

The information contained in this article is intended for general information purposes only and is based on information available as of the initial date of publication. No representation is made that the information or references are complete or remain current. This article is not a substitute for review of current applicable government regulations, industry standards, or other standards specific to your business and/or activities and should not be construed as legal advice or opinion. Readers with specific questions should refer to the applicable standards or consult with an attorney.