Radon Detection & Awareness in Facilities

By Grainger Editorial Staff 4/6/23

A colorless and odorless radioactive gas, radon is found in many workplaces and homes throughout the United States. According to the Environmental Protection Agency (EPA), radon is produced from the decay of uranium found in rocks and soils. As radon escapes into the air from the ground, it produces radioactive particles that can damage DNA when inhaled, leading to an increased risk of lung cancer. Radon is the second leading cause of lung cancer and approximately 21,000 Americans die each year from radon-related lung cancer, according to the EPA. Learn testing and mitigation strategies to help reduce the risk of radon exposure.

Radon in Buildings

Some amounts of radon are found everywhere— in the soil, water, and air. High radon levels often occur in areas where soil and rock are rich in uranium. Homes, schools, buildings, and indoor workplaces can have high radon levels. This applies to old and new properties and those with or without basements. According to the EPA, radon enters homes and buildings in several ways, including through floor or wall cracks, construction joints, gaps around pipes, sump pumps, drains or suspended floors. While entry through foundations is the primary concern, radon can also enter buildings through the water supply. Radon problems in drinking water are much more common in private and public wells rather than surface water supplied systems.

Testing and Remediation

Since radon can't be seen or smelled, special equipment is required to detect it. Radon gas can easily be detected and monitored using two different test methods. The most commonly used method is passive radon testing. Passive devices don't require power and are placed in an area of a structure for a set period of time, then sealed and sent to a laboratory for analysis. According to the EPA, passive testing devices include charcoal canisters, charcoal liquid scintillation devices and alpha‑track detectors. There are two types of passive radon tests, short-term and long-term.

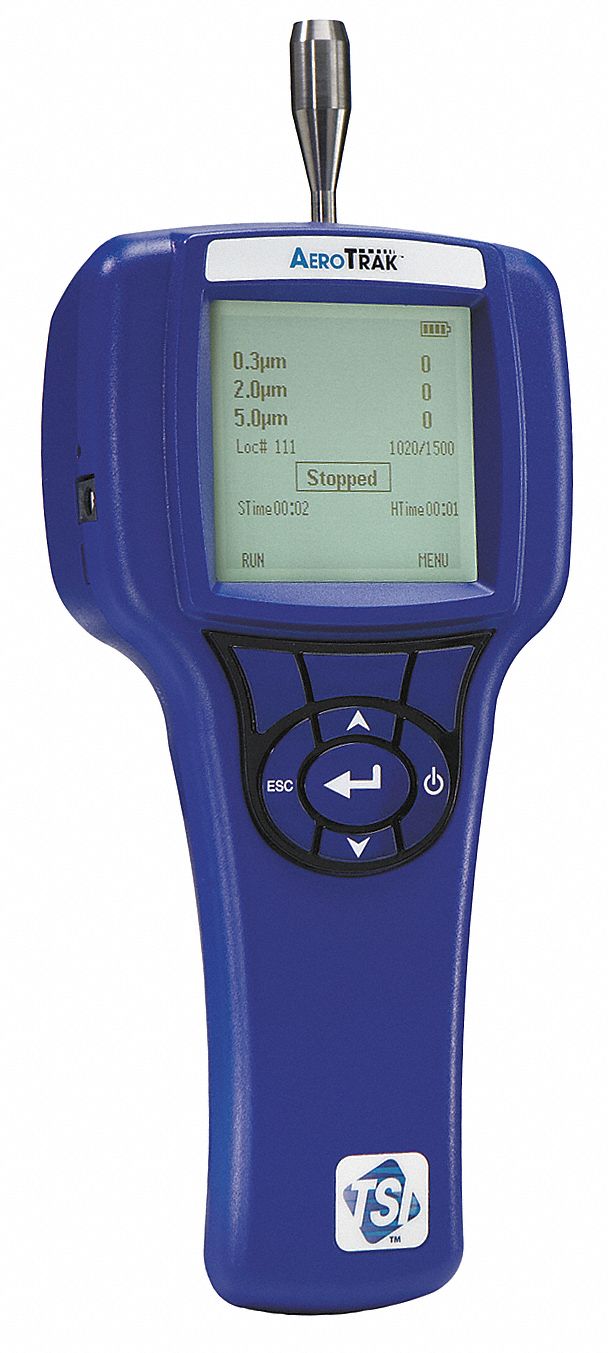

The other method for detecting radon gas uses active monitors. These monitors require a power source and provide an instantaneous readout at any given time. Some units can calculate short-term and long-term radon levels.

Short-term vs. Long-term Testing

According to the EPA, since radon levels often vary daily and depending on the season, a long-term test is more helpful for determining your year-round average radon level than a short-term test. However, if you need results quickly, a short-term test can help determine which areas should be fixed. Depending on the device, short-term tests remain for two to 90 days, whereas long-term tests are used to check radon levels beyond 90 days. Whether you hire a professional or conduct the test yourself, all radon tests should last at least 48 hours.

Radon Levels

Radon levels are measured according to picocuries per liter of air, or pCi/L. The EPA recommends remediation when radon levels reach 4 pCi/L to help reduce exposure. According to the EPA, basement or first-floor testing is recommended since radon levels are often elevated in the lowest part of a home or building.

Mitigation Strategies

EHS Daily Advisor notes radon mitigation approaches for commercial buildings are similar to those used in individual homes. The radon present must be pulled from the soil below the building using mitigation systems like an inline duct fan to pump the gas out through a pipe above the roof of the building. Builders can also proactively install mitigation systems in new buildings, ensuring radon can be directed out immediately when detected.

The EPA recommends three ways to help reduce radon exposure in larger buildings like school and office buildings, including:

- Sealing all potential radon entry points

- Pressurizing the building's HVAC system

- Installing an active-soil depressurization (ASD) system

Protecting Workers from Radon

Workers performing restoration work in homes and buildings can be at risk for radon exposure. A 2022 study by the University of California at Irvine found a strong connection between prolonged exposure to low radon levels and lung cancer, demonstrating a need for greater protection measures. Employers and workers can help minimize exposure to radon by following OSHA's Hazardous Waste Operations and Emergency Response (29 CFR 1910.120) and Ionizing Radiation (29 CFR 1910.1096 and 29 CFR 1926.53) standards. Air monitoring can help alert workers about high radon levels in a work site, including homes and other residential buildings.

The EPA, Housing and Urban Development (HUD), OSHA and the National Institute of Health developed a worker guide for dealing with radon issues. When working in areas with increased radon levels, worker protection includes using engineering controls, PPE and work practices to help limit exposure, including:

Engineering Controls

- Installing a radon remediation system

Personal Protective Equipment (PPE)

- A NIOSH-approved particulate-filtering respirator can help reduce the inhalation of radon and other radioactive particles within the working environment.

Recommended Work Practices

- Opening windows and doors to help ventilate the structure. Ensuring that working areas receive plenty of fresh air can help disperse radon gas from the working environment.

- Avoiding eating, drinking or smoking in work areas.

Frequently Asked Questions

Q: What are the OSHA guidelines for radon exposure?

A: The OSHA radon permissible exposure limit for employees is 100 pCi/L, within a 40-hour workweek over 7 consecutive days. The OSHA standard 1910.1096 also requires employers to evaluate the workplace as necessary, including the radiation levels of materials, equipment and the location.

Q: How often should you test for radon?

A: The EPA recommends testing for radon if the last test wasn't within the last two years, after a building was renovated or when buying or selling a property. Additionally, if the building's water is supplied via a private well or a public water supply using groundwater, it should be tested for radon.

The information contained in this article is intended for general information purposes only and is based on information available as of the initial date of publication. No representation is made that the information or references are complete or remain current. This article is not a substitute for review of current applicable government regulations, industry standards, or other standards specific to your business and/or activities and should not be construed as legal advice or opinion. Readers with specific questions should refer to the applicable standards or consult with an attorney.