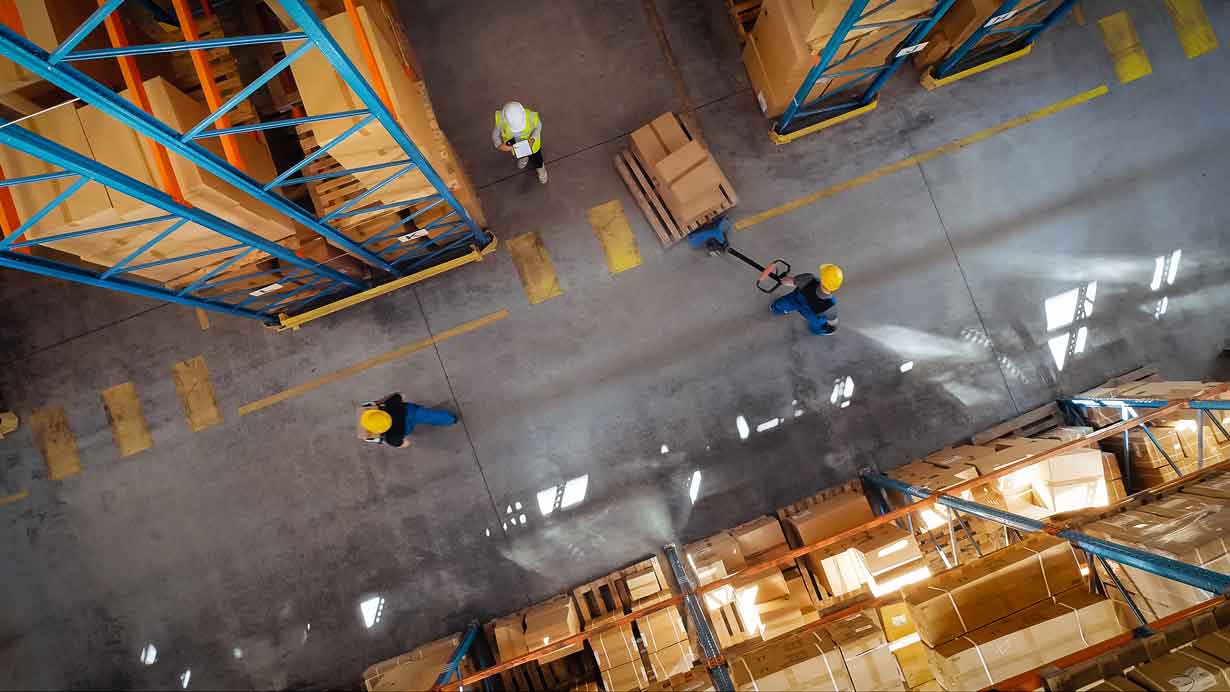

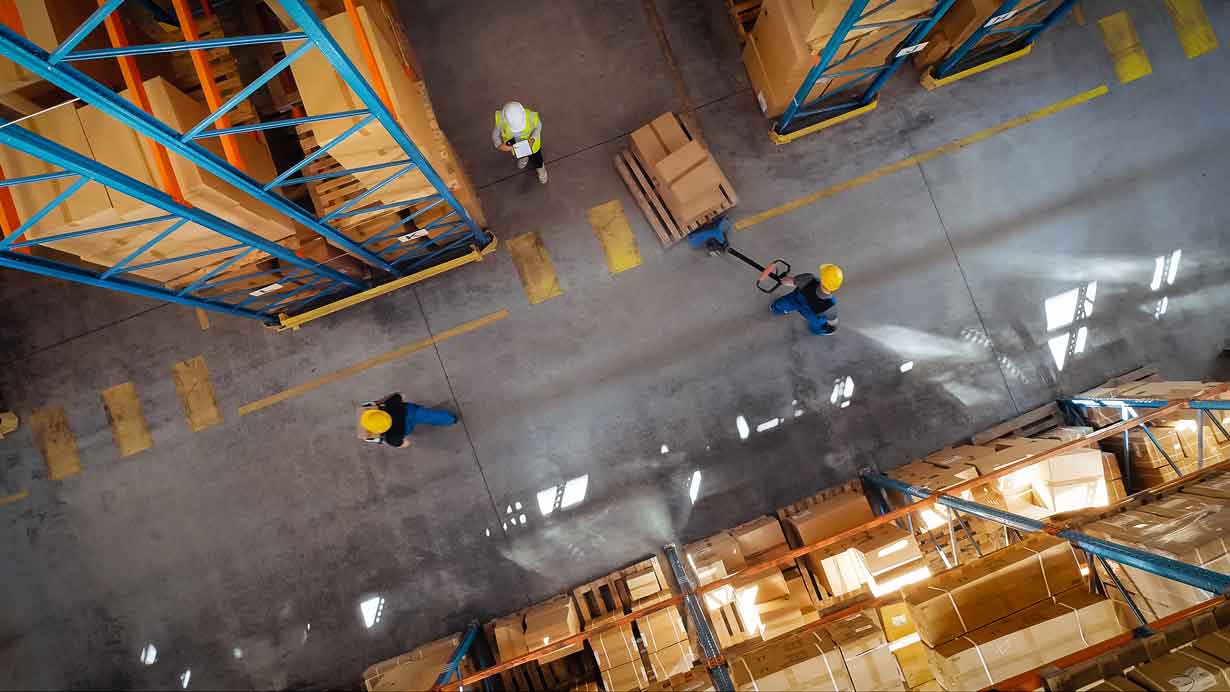

Warehouse Ergonomics Tips to Help Reduce Strain and Injuries

By Grainger Editorial Staff 1/6/26

Warehousing and distribution work often involves physical demands that can lead to strain over time. Learn how OSHA’s Warehousing NEP highlights common ergonomic risks and how practical adjustments and equipment can help support safer work activities.

Warehousing and distribution work often involves frequent lifting, pallet handling, pushing and pulling loads and long periods of standing. While these activities are essential to keeping operations moving, they can also cause repeated physical strain over time.

OSHA is operating a National Emphasis Program (NEP) focused on warehousing and distribution work, with inspections expected to continue through 2026. The program followed years of injury and illness data showing similar patterns across warehouses, distribution centers and some retail operations.

While the NEP has a defined timeframe, the hazards it highlights reflect long-standing safety challenges that extend beyond the program's lifespan.

Why Ergonomics Remains an Ongoing Priority for OSHA

Musculoskeletal disorders continue to be one of the most common causes of days away from work in warehousing environments. Tasks involving repetitive lifting, awkward postures and forceful exertion can contribute to strains, sprains and fatigue, even in facilities with established safety programs.

OSHA evaluates ergonomic risks through injury log reviews, employee interviews and walkthrough observations, both under emphasis programs and during general inspections. Looking closely at how everyday work is done can often reveal opportunities to help reduce physical strain and support worker comfort over time.

Many of the same ergonomic challenges also appear during maintenance work, such as equipment servicing, part replacement and routine facility upkeep.

OSHA’s Warehousing NEP

The Warehousing and Distribution Center NEP covers warehouses, distribution centers, mail and parcel delivery operations and select retail locations with elevated injury rates related to storage and loading activities.

Under the NEP, inspections place added emphasis on common warehouse conditions, including how materials are handled and stored, how equipment is used and whether walking areas and exit routes are kept clear. Inspectors also pay attention to tasks that involve repeated motion, sustained physical effort or added strain from heat.

While the NEP increases inspection attention, it isn't introducing new ergonomic requirements. It’s helping reinforce the importance of addressing long-standing physical demands that are already part of daily warehouse and maintenance work. OSHA also doesn’t require specific ergonomic equipment. Instead, employers are responsible for identifying recognized hazards, including ergonomic risks, and determining how best to address them based on their work environment and tasks.

Key Ergonomic Focus Areas in Warehousing

Most ergonomic challenges in warehouses come from routine work activities. Reaching down or overhead, moving pallets by hand, pushing or pulling loaded equipment, standing on hard floors, and using workstations that aren’t a good fit can all take a toll over time.

Reducing Strain During Lifting

Managing load height during lifting can help reduce stress on the body. Equipment like lift tables, turntables and pallet positioners can help keep materials closer to a neutral working height as loads are built, broken down or repositioned. By reducing the need for repeated bending or reaching, these solutions can help support safer material-handling tasks.

Moving pallets manually can also place significant strain on workers, especially in busy or confined areas. Pallet trucks and jacks are commonly used to help support safer pallet movement by improving control and reducing push-and-pull effort during routine transport tasks.

Transporting Materials Safely

Transporting materials throughout a warehouse often involves repeated pushing, pulling and maneuvering. When carts are difficult to steer or poorly balanced, these tasks can contribute to fatigue over time. Carts and trucks designed for material handling can help support smoother movement and better load distribution during picking, staging and delivery activities.

Reducing Fatigue from Prolonged Standing

Standing for long periods on hard floors is common in packing, inspection and sorting areas and can contribute to leg, foot and lower back discomfort. In areas where workers stand in one place, anti-fatigue mats are often used to help absorb shock and encourage subtle movement, which can help reduce fatigue. Beyond matting, additional steps can be taken for tasks that involve prolonged standing. In some situations, accessories such as kneeling pads or task seating can be used along with other ergonomic improvements.

Improving Workstations for Repetitive Tasks

Workstations that are too high or too low can sometimes create awkward postures that increase strain during repetitive work. Adjustable workbenches and workstations can help align work surfaces with the task being performed, supporting more comfortable working heights and better posture during assembly, packing and inspection activities.

Inspection Readiness

Whether during an active emphasis program or a routine inspection, OSHA often examines injury trends, observes work practices, and speaks directly with employees. Information from injury logs, worker feedback and walkthrough observations can help bring potential ergonomic risks into focus.

From an operational standpoint, taking a closer look at material-handling tasks can help identify where physical strain occurs during regular operations. Addressing those areas through engineering controls can also help support ongoing safety efforts, even outside of enforcement cycles.

RECOMMENDED KNOWHOW FOR YOU

PPE in the Workplace

Safety Essentials: Protecting Employees and Supporting Compliance

Learn how the right safety supplies and processes can help support compliance, reduce injuries and protect employees throughout the workday.

![]() Our Latest KnowHow

Our Latest KnowHow

How to Choose the Right Ceiling Tiles

Ceiling tiles are made of different materials to serve a variety of purposes, so make sure you're choosing the right kind of ceiling tile for your facility.

The information contained in this article is intended for general information purposes only and is based on information available as of the initial date of publication. No representation is made that the information or references are complete or remain current. This article is not a substitute for review of current applicable government regulations, industry standards, or other standards specific to your business and/or activities and should not be construed as legal advice or opinion. Readers with specific questions should refer to the applicable standards or consult with an attorney.