PPE for 3 Major Electrical Hazards

By Grainger Editorial Staff 5/17/22

Working with energized equipment presents unique hazards, including the threat of electrocution and severe burns from an arcing fault. For employees working with electrical components in or near “energized” environments, the need for standards, rules, and safety-related products designed to protect their health is critical.

OSHA requires employers to provide electrical PPE appropriate to the body part and the work being performed. Electrical PPE is designed to reduce three major hazards of working with energized equipment: electric shock, arc flash, and arc blast.

The Last Line of Defense

PPE is only a small part of a comprehensive electrical safety program, which should include training, administrative controls and thorough risk assessment. To help better protect workers against electrical hazards, the National Fire Prevention Association (NFPA) maintains standard 70E, a comprehensive guide for establishing an electrical safety program in the workplace.

PPE is not a substitute for other risk mitigation measures. The NFPA places PPE at the very bottom of its electrical risk management hierarchy, only to be used once other avenues have been exhausted. Whenever possible, the NFPA recommends either eliminating the electrical risk by powering down the equipment, substituting a less risky approach to completing the task or installing engineering controls like remote-racking switchgear that can keep workers clear of electrical hazards.

However, working with energized equipment is sometimes unavoidable. Powering down a circuit may create greater hazards, for example when shutting off the power would stop the ventilation of flammable gas in a confined space. Or it may not be possible to troubleshoot an issue with a piece of equipment after it has been powered down. And for some switches, opening and closing the circuit itself is a hazardous task. For these jobs, electrical PPE is required.

Protecting Against Electric Shock

Electric shock is the most straightforward hazard to address. It occurs when electrical current flows through a worker’s body. To lessen the potential for shock, workers are required to wear proper PPE, which includes insulated rubber gloves and sleeves, when working within a limited approach boundary (a safe distance at which a shock hazard exists), or a restricted approach boundary (where there is an increased risk of shock).

Insulated gloves are grouped into six classes, depending on their level of protection. They should be inspected before each use and tested on a required cadence by accredited labs.

For most jobs, OSHA requires leather glove protectors be worn over rubber insulating gloves. Glove protectors can prevent cuts and tears that would compromise the glove’s protective rubber insulation.

Since small punctures or cracks in insulating gloves can be dangerous, insulating gloves must be inspected before each use and retested every six months. Gloves must be tested by a laboratory accredited by the North American Independent Laboratories for Protective Equipment Testing.

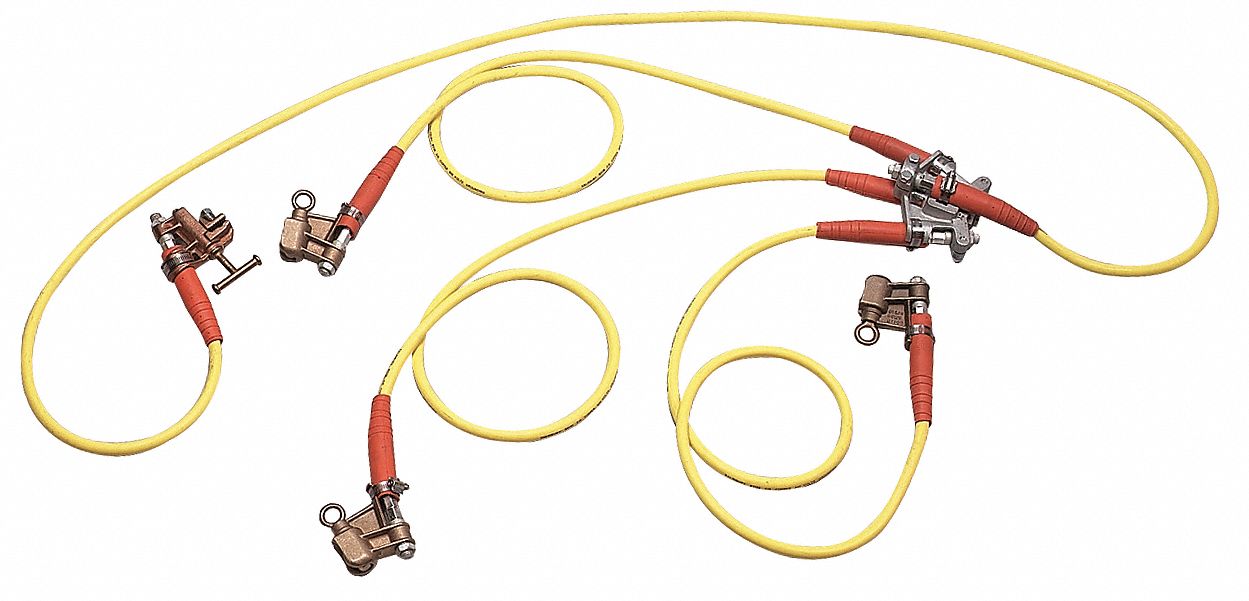

Insulated mats and blankets are another PPE option for reducing electric shock hazard. Blankets can be used to shield energized equipment during maintenance, preventing contact with workers.

Protecting Against Arc Flash

Arc flash is the second electrical hazard. A fault can occur when electrical current jumps the gap between energized equipment and a potential ground. According to Fluke, temperatures from an arc flash can reach 35,000 degrees. Temperatures this high can ignite clothing several feet away resulting in serious if not fatal injuries.

When selecting PPE to mitigate arc flash hazards, it’s important to remember that the intense heat from an arc flash can harm workers standing as far as 40 feet from the equipment. The area at risk is known as the arc flash boundary, the furthest distance at which an arc from the equipment could cause the onset of second-degree burns. It is determined by the amount of current carried in the equipment and the response time of protective fuses or circuit breakers.

Any body part within the arc flash boundary needs to be covered with arc flash resistant PPE, which includes masks, hoods, coveralls, jackets and balaclavas. These clothes are heat and flame resistant and are designed to protect the wearer against the extreme heat from an electrical arc, which is measured in calories per square centimeter.

Like gloves, arc flash PPE is divided into categories, depending on the level of protection provided. Category 1 protects against heat intensity of 4 calories per square centimeter, which the NFPA estimates could be produced by an arc from a 240-volt panel. The highest level of protection, Category 4, protects against 40 calories per square centimeter, the level of arc intensity which could be emitted from metal-clad 15-kilovolt switchgear.

Protecting Against Arc Blast

Finally, the energy released by a fault can create an arc blast, a concussive shockwave caused by the extreme heat surrounding an electrical arc. An arc blast can cause permanent hearing loss and other organ damage. It also can throw shrapnel and molten metal, which can cause puncture wounds. To protect against arc blast, the NFPA recommends wearing hearing protection, eye protection, and hard hats while working within the arc flash boundary.

The information contained in this article is intended for general information purposes only and is based on information available as of the initial date of publication. No representation is made that the information or references are complete or remain current. This article is not a substitute for review of current applicable government regulations, industry standards, or other standards specific to your business and/or activities and should not be construed as legal advice or opinion. Readers with specific questions should refer to the applicable standards or consult with an attorney.