Hazardous Locations: Classes, Divisions and Groups

By Grainger Editorial Staff 9/30/20

Quick Tips #124.1

A major safety concern in all workplaces is the occurrence of fires and explosions. No other aspect of safety receives more attention in the form of codes and standards. Electrical equipment can and does cause fires and/or explosions in certain atmospheres. To minimize the risk of these fires or explosions, electrical/electronic equipment must be designed, tested and labeled as being acceptable for use in the areas in which it is installed.

Hazardous classified locations are areas where the possibility of fire or explosion hazards may exist under normal or abnormal conditions because of the presence of flammable, combustible or ignitable gases, vapors, liquids, dust, or fibers/flyings. These areas are classified solely for the purpose of ensuring the safe and proper specification and installation of electrical/electronic equipment.

Standards for electrical installations have been established and are governed by a variety of organizations throughout the world to ensure safe electrical systems in hazardous locations.

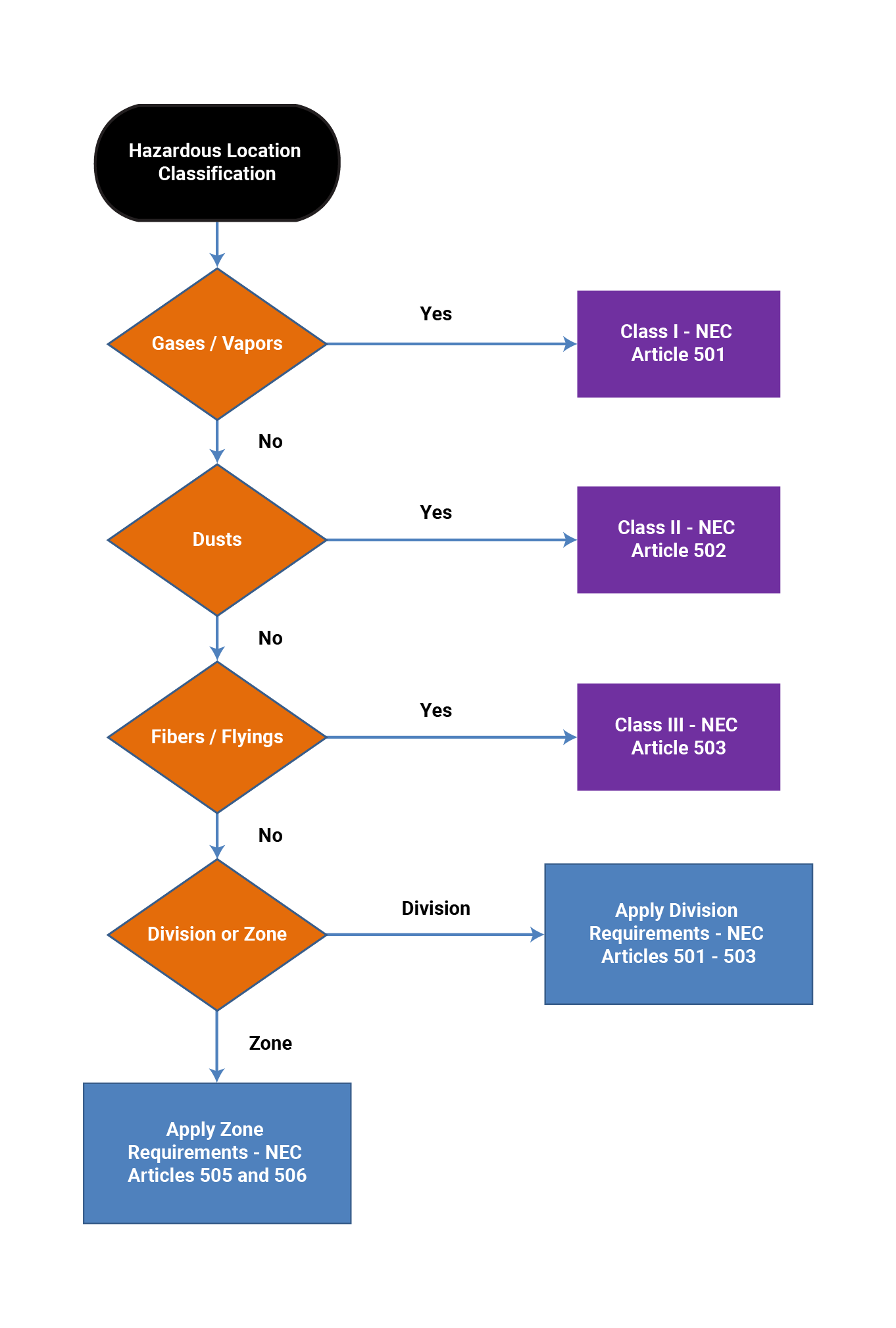

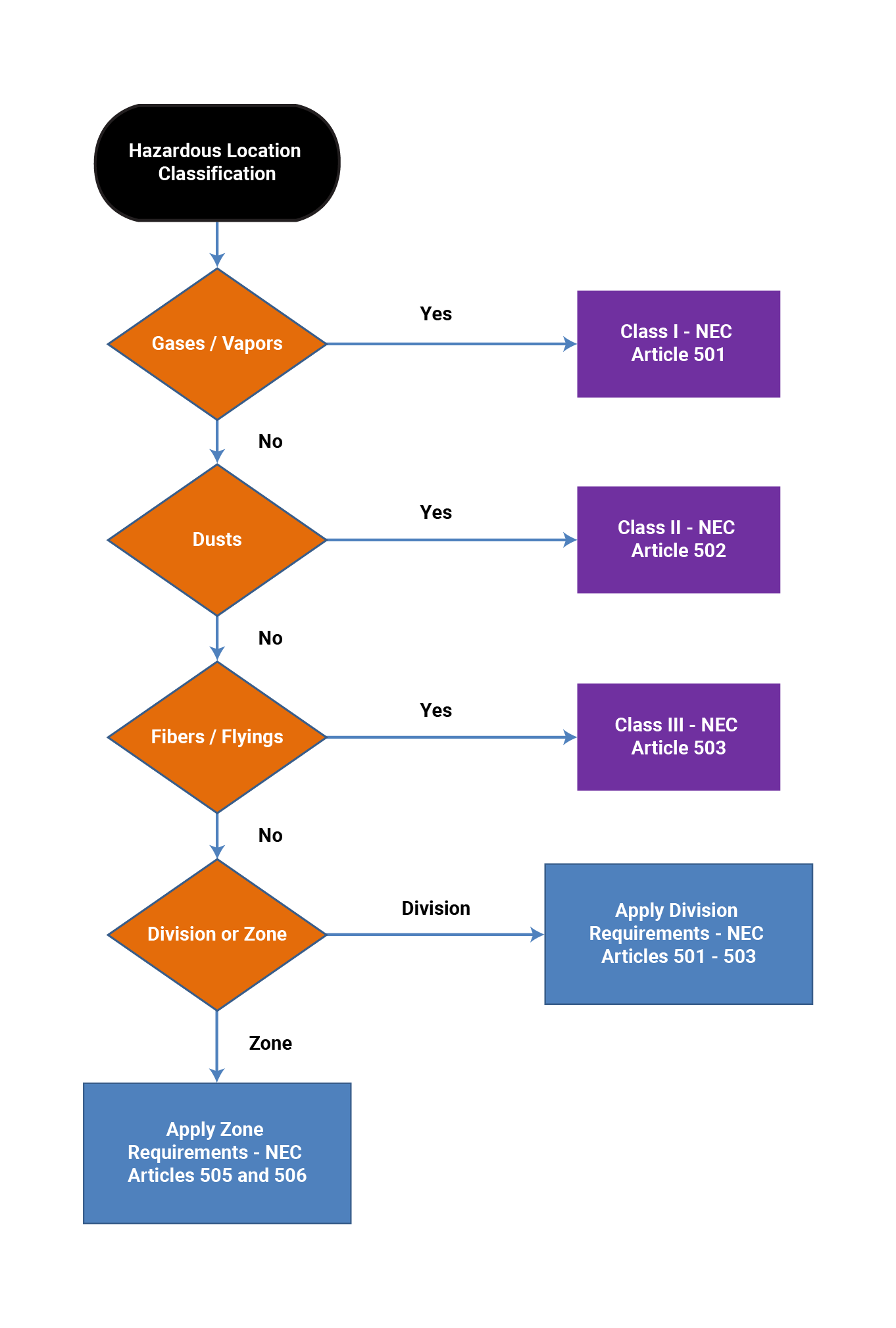

In the United States, the hazardous location classification system is defined by the National Fire Protection Association (NFPA) 70®, National Electric Code® (NEC). NFPA 70 NEC uses the familiar Class/Division system and has added an Americanized version of the International Electrochemical Commission’s (IEC) IEC Zone system which maintains the NEC wiring methods and protection techniques.

NFPA 70 NEC Articles 500 through 503 cover the requirements for electrical/electronic equipment and wiring for all voltages in Class I, Divisions 1 and 2; Class II, Divisions 1 and 2; and Class III, Divisions 1 and 2 locations.

NFPA 70 NEC Articles 505 and 506 cover the requirements for the Americanized Zone classification system as an alternative to the Class and Division classification system.

NFPA 70 NEC Classes, Divisions and Groups

NFPA 70 NEC establishes area classifications based on Classes, Divisions and Groups that when combined delineate the hazardous conditions of a specific area. This classification method provides a description of the hazardous material that may be present, and the probability that it is present, so that the appropriate equipment may be selected, and safe installation practices followed.

The Occupational Safety and Health Administration (OSHA) has adopted these hazardous classifications and all except “Groups” are defined in 29 Code of Federal Register (CFR) 1910.399. In 29 CFR 1910.307(c)(2)(ii), OSHA requires all equipment used in a hazardous location to be marked with the class, group and operating temperature or temperature range for which it is approved. Although OSHA does not provide a definition of group classifications in 29 CFR 1910.307 or 399 they do provide a note under 29 CFR 1910.307(c)(1) that states: “NFPA 70, the National Electrical Code, lists or defines hazardous gases, vapors, and dusts by “Groups” characterized by their ignitable or combustible properties.” To meet OSHA’s marking requirement, the marking must include the hazardous group the equipment is approved to operate in.

Class defines the type of explosive or ignitable substances which are present in the atmosphere. Division defines the likelihood of the hazardous material being present in an explosive or ignitable concentration.Class I flammable gases and vapors are grouped into one of four groups (Groups A, B, C or D) based on their physical properties and the ease in which they can be ignited. Class II combustible dusts are grouped into one of three (3) groups: E combustible metal dusts, F combustible carbonaceous dusts or G other combustible dusts.

| NFPA 70 NEC Hazardous Locations Classes, Divisions and Groups | ||

|---|---|---|

| Class | Division | Group |

| I – Flammable gases or vapors may be present | 1 – Ignitable concentrations of hazards exist under normal operation conditions and/or where the hazard is caused by frequent maintenance or repair work or frequent equipment failure 2 – Ignitable concentrations of hazards exist under abnormal operation conditions |

Group A – Acetylene Group B – hydrogen, butadiene, ethylene oxide, propylene oxide and acrolein Group C – Ethylene, cyclopropane and ethyl ether Group D – Acetone, ammonia, benzene, butane, ethanol, gasoline, hexane, methane, methanol, methane, naphtha, natural gas, propane and toluene |

| II – Combustible dust may be present | 1 – Ignitable concentrations of hazards exist under normal operation conditions and/or where the hazard is caused by frequent maintenance or repair work or frequent equipment failure 2 – Ignitable concentrations of hazards exist under abnormal operation conditions |

E – Combustible metal dusts: aluminum, commercial alloys and magnesium F – Combustible carbonaceous dusts: carbon black, charcoal, coal and coke dusts G – Other combustible dusts: Chemicals, flour, grain, plastic and wood |

| III – Easily ignitable fibers or flyings may be present | 1 – Ignitable concentrations of hazards exist under normal operation conditions and/or where the hazard is caused by frequent maintenance or repair work or frequent equipment failure 2 – Ignitable concentrations of hazards exist under abnormal operation conditions |

Not Applicable |

NFPA 70 NEC Zone Classification System

The Zone Classification System is offered as an alternative to the Class and Division system. It is an Americanized version of the International Electrochemical Commission’s (IEC) Zone system which maintains the NEC wiring methods and protection techniques. Zone defines the general nature – if it is a gas or dust – and the probability of hazardous material being present in an ignitable concentration in the surrounding atmosphere. The Zones are based on how often the hazard is present rather than upon normal versus abnormal conditions.

| NFPA 70 NEC Hazardous Locations Zones | |

|---|---|

| Gases, Vapors and Mists | 0 – Ignitable concentrations of flammable gases or vapors which are present continuously or for long periods of time |

| 1 – Ignitable concentrations of flammable gases or vapors which are likely to occur under normal operating conditions; may exist frequently because of repair/maintenance operations or leakage; or equipment is operated in a manner that equipment breakdown/faulty operations could result in the release of ignitable concentrations of flammable gases or vapors and failure of the equipment | |

| 2 – Ignitable concentrations of flammable gases or vapors which are not likely to occur under normal operating conditions and if they do will only persist for a short period of time; or volatile flammable liquids, gases, or vapors are confined within closed containers/systems and can escape only as a result of an accidental rupture; or volatile flammable liquids, gases, or vapors are normally prevented by positive mechanical ventilation, but may become hazardous due to system failure | |

| Dusts and Fibers/Flyings | 20 – Combustible dusts or ignitable fibers/flyings are present continuously or for long periods of time |

| 21 – Combustible dusts or ignitable fibers/flyings are likely to occur under normal operating conditions; or may exist frequently because of repair/maintenance operations or leakage; or equipment is operated in a manner that breakdown/faulty operations could result in the release of ignitable concentrations of combustible dust or fibers/flyings and failure of the equipment | |

| 22 – Combustible dusts or ignitable fibers/flyings are likely to occur under normal operating conditions; or may exist frequently because of repair/maintenance operations or leakage; or equipment is operated in a manner that breakdown/faulty operations could result in the release of ignitable concentrations of combustible dust or fibers/flyings and failure of the equipment | |

Group defines the type of hazardous material and partly the location of the surrounding atmosphere .

| NFPA 70 NEC Hazardous Locations Groups | ||

|---|---|---|

| Group I | Group II | Group III |

| Mines susceptible to firedamp (flammable mixture of gases naturally occurring in a mine | Explosive gas atmospheres other than mines susceptible to firedamp – Group II equipment is subdivided into three subgroups | Explosive dusts – Group III equipment is subdivided into three subgroups |

| A – Atmospheres containing acetone, ammonia, ethyl alcohol, gasoline, methane, propane, or gases/vapors of equivalent hazard | A – Atmospheres containing solid particles and fibers greater than 500 microns that could be suspended in air and settle out | |

| B– Atmospheres containing acetaldehyde, ethylene, or gases / vapors of equivalent hazard | B – Atmospheres containing combustible dusts other than combustible metal dusts | |

| C – Atmospheres containing acetylene, hydrogen, or gases/vapors of equivalent hazard | C – Atmospheres containing combustible metal dusts | |

Conclusion

Determining the Class, Division and Group or Zone and Group is critical to correctly applying the requirements for a given hazardous location. Comparisons between the two systems are not easily accomplished. Which system is preferred depends on the user’s preference, how the areas are classified, and the wiring system used. The Zone system has wider use in the chemical and petrochemical industries. Shown below is a summary of the applicable NEC Articles to reference to ensure the proper requirements are applied.

Commonly Asked Questions

Q: Can I use a piece of equipment approved for use in a Division 1 hazardous location in a Division 2 hazardous location?

A: Yes. If equipment has been approved for use in a Division 1 hazardous location, it can be used in a Division 2 hazardous location, providing it is in the same class and group.

Q: Can equipment approved for a Class I hazardous location be used in a Class II hazardous location?

A: No. Equipment approved for use in Class I hazardous locations cannot be used in Class II hazardous locations.

Q: Are Divisions and Zones equivalent to one another?

A: When comparing Divisions and Zones, Division 2 is equivalent to Zone 2, but Division 1 is equivalent to either Zone 0 or 1.

Sources

29 CFR 1910.307 – Hazardous (classified) Locations

29 CFR 1910.399 – Definitions Applicable to Subpart S

National Electric Code 2020 edition – National Fire Protection Association

![]()

The information contained in this article is intended for general information purposes only and is based on information available as of the initial date of publication. No representation is made that the information or references are complete or remain current. This article is not a substitute for review of current applicable government regulations, industry standards, or other standards specific to your business and/or activities and should not be construed as legal advice or opinion. Readers with specific questions should refer to the applicable standards or consult with an attorney.