Procure the Right PPE for Chemical Manufacturing

By Grainger Editorial Staff 3/3/26

Learn which PPE helps protect against chemical hazards in manufacturing. Explore protection for eyes, lungs, skin, and more to help meet safety regulations and reduce exposure risks.

Many employees in chemical manufacturing are exposed to hazardous chemicals such as cleaning chemicals, process chemicals, research chemicals and more. Controlling exposure to these chemical hazards is fundamental to protecting employees. The hierarchy of controls is a systematic way to group hazard control methods according to their effectiveness by considering the most effective methods before less effective methods. The inverted triangle of the hierarchy has elimination at the top and is the most desirable control followed by substitution of a less hazardous chemical. If a chemical hazard cannot be eliminated or substituted then engineering and administrative controls should be used first, with PPE helping reduce remaining exposure.

Need for PPE

PPE is designed to provide protection from injuries and illnesses resulting from exposure to a variety of hazardous chemicals and substances. According to OSHA, chemical-resistant PPE needs to protect the eyes and face, hearing, respiratory, body, hands and feet, be able to stand up to certain chemical hazards and guard against splashes and vapors created during the manufacturing process.

Eye and Face Protection

Eye and face protection must protect wearers from the hazards associated with chemical splashes. Exposure to industrial and cleaning chemicals is a common cause of chemical burns to the eyes and face. Chemical safety goggles form an airtight seal around the wearer’s face, preventing any liquids or fumes from reaching the eyes. Face shields block splashes by covering the worker’s face with a clear plastic visor that can also offer heat and impact resistance.

Hearing Protection

Many workers are exposed to noise in the workplace every day but when uncontrolled, this exposure may cause permanent hearing loss. In addition, research shows that exposure to ototoxicants, such as pesticides, solvents and pharmaceuticals, can cause hearing loss or balance problems, regardless of noise exposure. Wearing hearing protection can protect the ears from noise. Exposure to ototoxicants should be controlled through engineering controls, ventilation and appropriate respiratory protection.

Respirators

Appropriate respirators should be used to protect against adverse health effects caused by inhaling chemicals and gases. Full-face respirators cover the wearer’s entire face and form a seal, so that only filtered or externally supplied breathing air enters the mask. Replaceable contaminant-specific cartridges help filter chemicals to reduce exposure. Supplied air respirators use compressed air from a remote source, typically outside of the contaminated areas. Powered air purifying respirators (PAPR) use a filter to purify the surrounding air and deliver filtered air into the attached facepiece or hood. Self-contained breathing apparatus (SCBA) respirators include their own portable air supply.

Clothing

Clothing protects a worker’s arms, legs and core from exposure due to chemical splashes. According to OSHA, skin protection PPE should be worn anytime a worker could be exposed to chemicals anywhere in the workplace. Chemical-resistant clothing can range from aprons and overalls to coveralls and encapsulated suits. The required level of protection, chemical resistance and suit design are the primary factors used when selecting chemical protective clothing.

Hand and Arm Protection

Gloves protect the hands and wrists from exposure to chemicals, with different levels of protection depending on the specific risks present. Disposable nitrile gloves may provide limited chemical splash protection while chemical-resistant gloves made of different rubber polymers may protect against direct exposure to a range of chemicals. Gloves can also include additional safety features, such as heat, cut and cold resistance. Chemical-resistant sleeves come in a variety of materials to protect the forearms and upper arms from chemical spills and splashes.

Footwear

Chemical-resistant footwear should be worn anytime a worker may be exposed to chemicals or corrosive materials. Boots made for chemical resistance will use materials such as PVC to cover the entire foot and lower leg. Boots can also include other safety features, such as puncture-resistant soles and steel toes.

Make sure you have the right chemical PPE in stock when and where you need it.

PPE in the Workplace

Procure the Right PPE for Chemical Manufacturing

See why employees in chemical manufacturing facilities need to choose the right personal protective equipment (PPE) to help limit chemical exposure.

![]() Our Latest KnowHow

Our Latest KnowHow

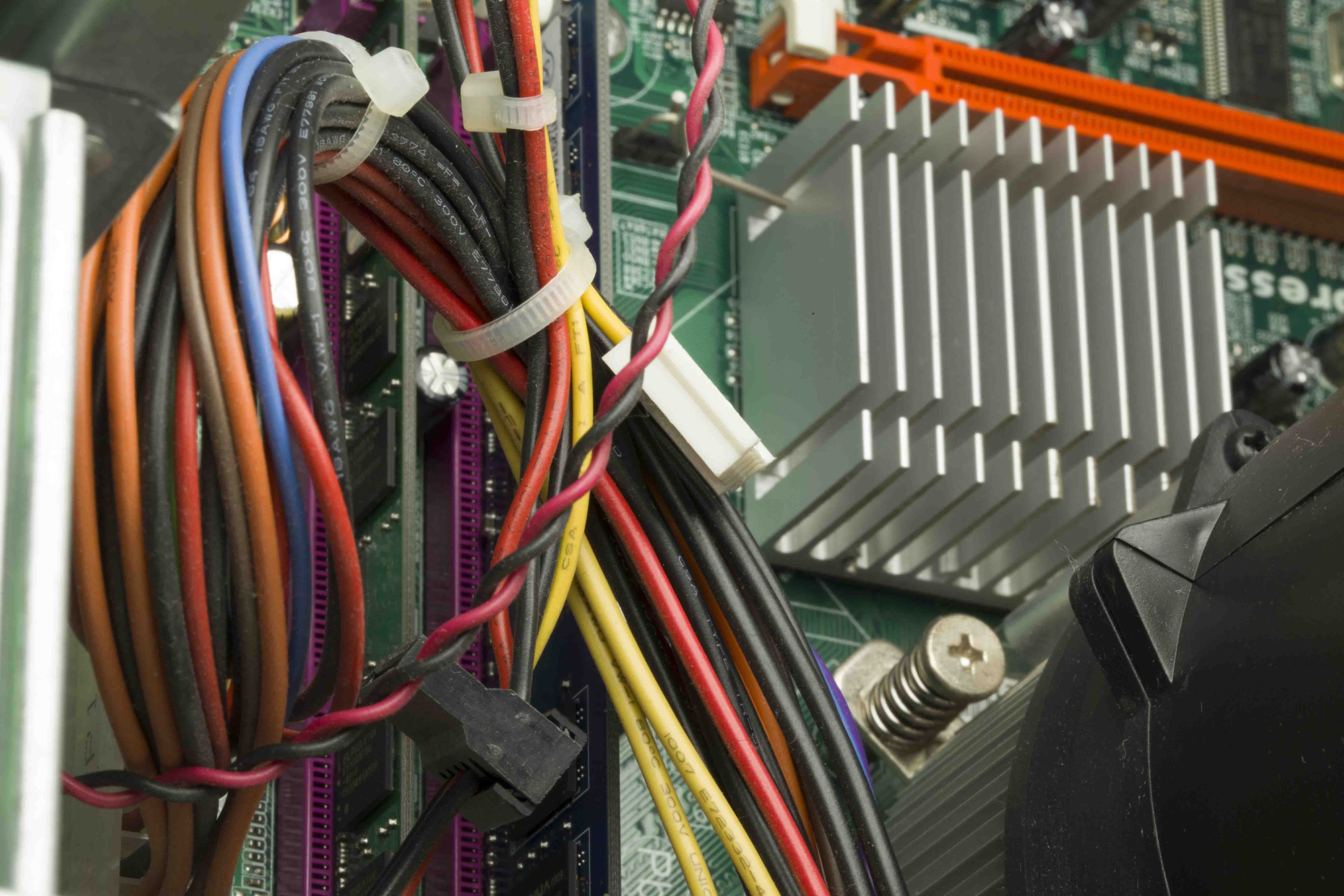

9 Tips for Wire and Cord Management at Work

Wire Management can be a real hassle in the office and warehouse. Learn from these 9 wire management tips to get the wire mess under control.

The information contained in this article is intended for general information purposes only and is based on information available as of the initial date of publication. No representation is made that the information or references are complete or remain current. This article is not a substitute for review of current applicable government regulations, industry standards, or other standards specific to your business and/or activities and should not be construed as legal advice or opinion. Readers with specific questions should refer to the applicable standards or consult with an attorney.