PPE in the Workplace

4 Reasons Why Workers Aren't Wearing PPE (And What to Do)

Here are four management problems that may be driving PPE noncompliance in your organization – and what you can do to help improve the situation.

12/21/23

PPE in the Workplace

PPE for Extreme Conditions: Ensuring Comfort and Safety in All Types of Weather

Learn more about the different types of specialized PPE designed to keep workers comfortable and safe in challenging environments.

10/25/23

PPE in the Workplace

4 Tips for Replacing Your Personal Protective Equipment

From gloves and boots to hard hats and fall protection, get to know the key signs it's time to replace your PPE.

09/13/23

PPE in the Workplace

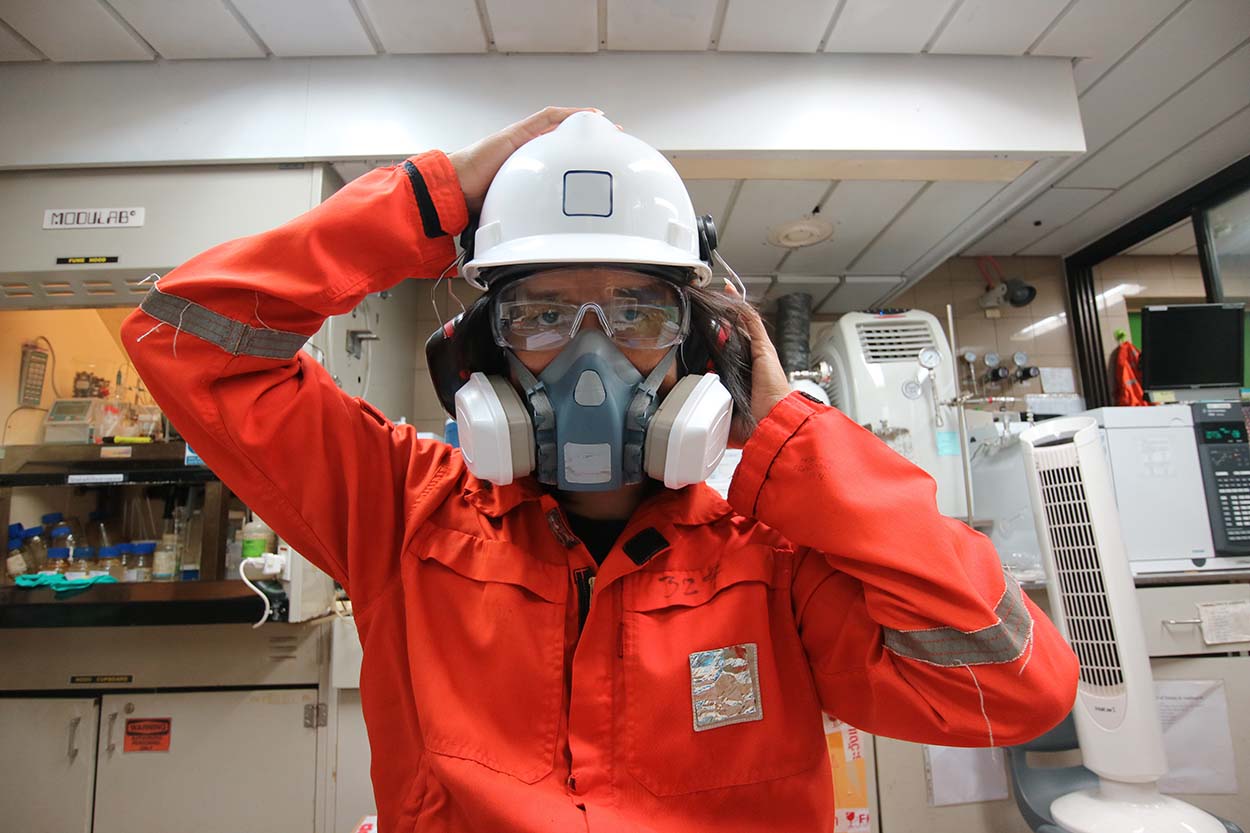

The Science of Fit and Fit Testing PPE for Worker Safety

This article and video talk about proper fit and fit testing PPE for worker safety. The article also explores PPE compatibility and why this is another important part of worker PPE fit testing.

09/10/23