PPE in the Workplace

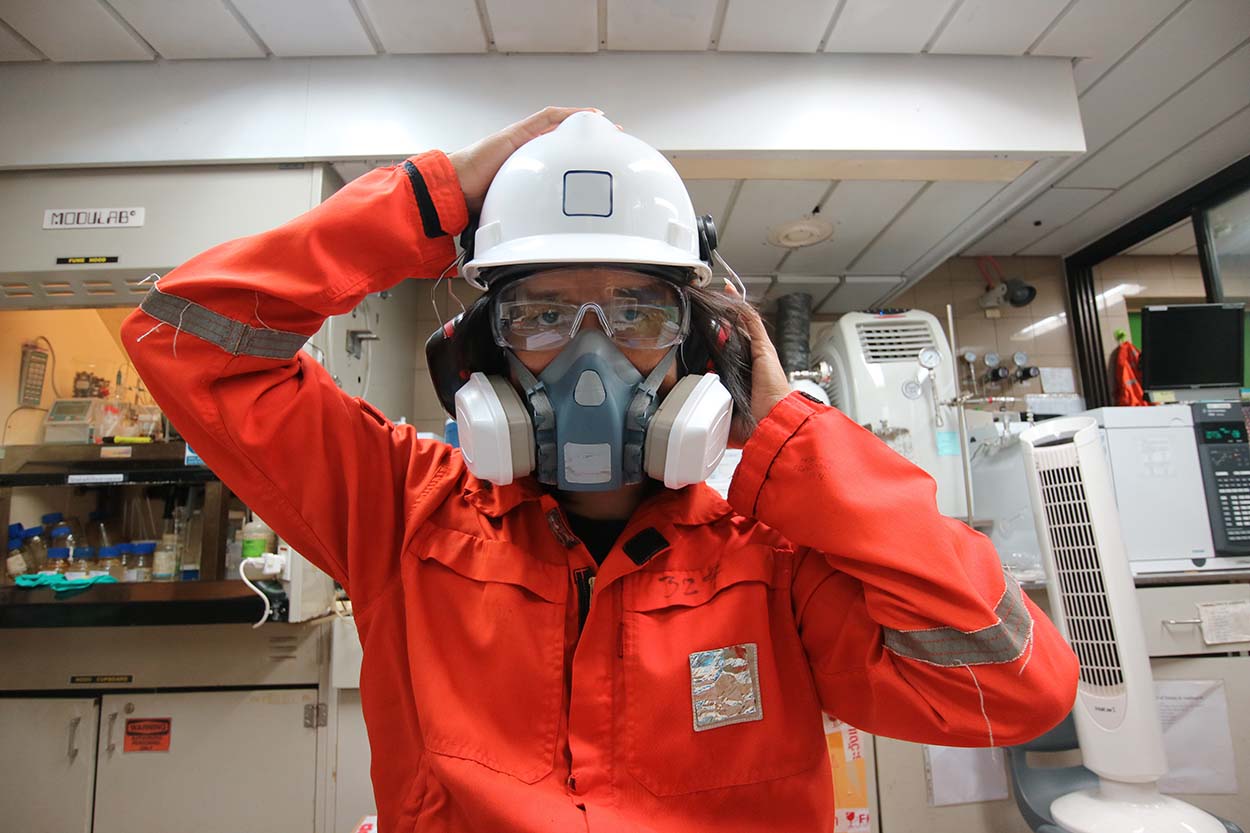

Types of Respiratory Protection Equipment

There are lots of different respirators to pick from. Check out this guide to the types of respiratory equipment and which will work for your workplace.

08/22/25

PPE in the Workplace

Is Your Job Putting Your Hearing at Risk?

Noise exposure is a major hazard for certain industries. Although occupational hearing loss can be permanent, there are simple ways employers and workers can work together to help protect hearing.

08/20/25

PPE in the Workplace

A Shoe for Every Work Occasion: Work Footwear You Need

In the market for work footwear? Choosing the right foot protection is essential for workplace safety. Learn how to choose the right work footwear for you.

08/01/25

PPE in the Workplace

Safety Quiz: How Much Do You Really Know About PPE?

How well do you know your safety gear? Test your knowledge with our short quiz to ensure you’re up to date with key safety practices.

05/02/24