Minimize Work Place Hazards with Engineering Control & PPE

By Grainger Editorial Staff 3/16/22

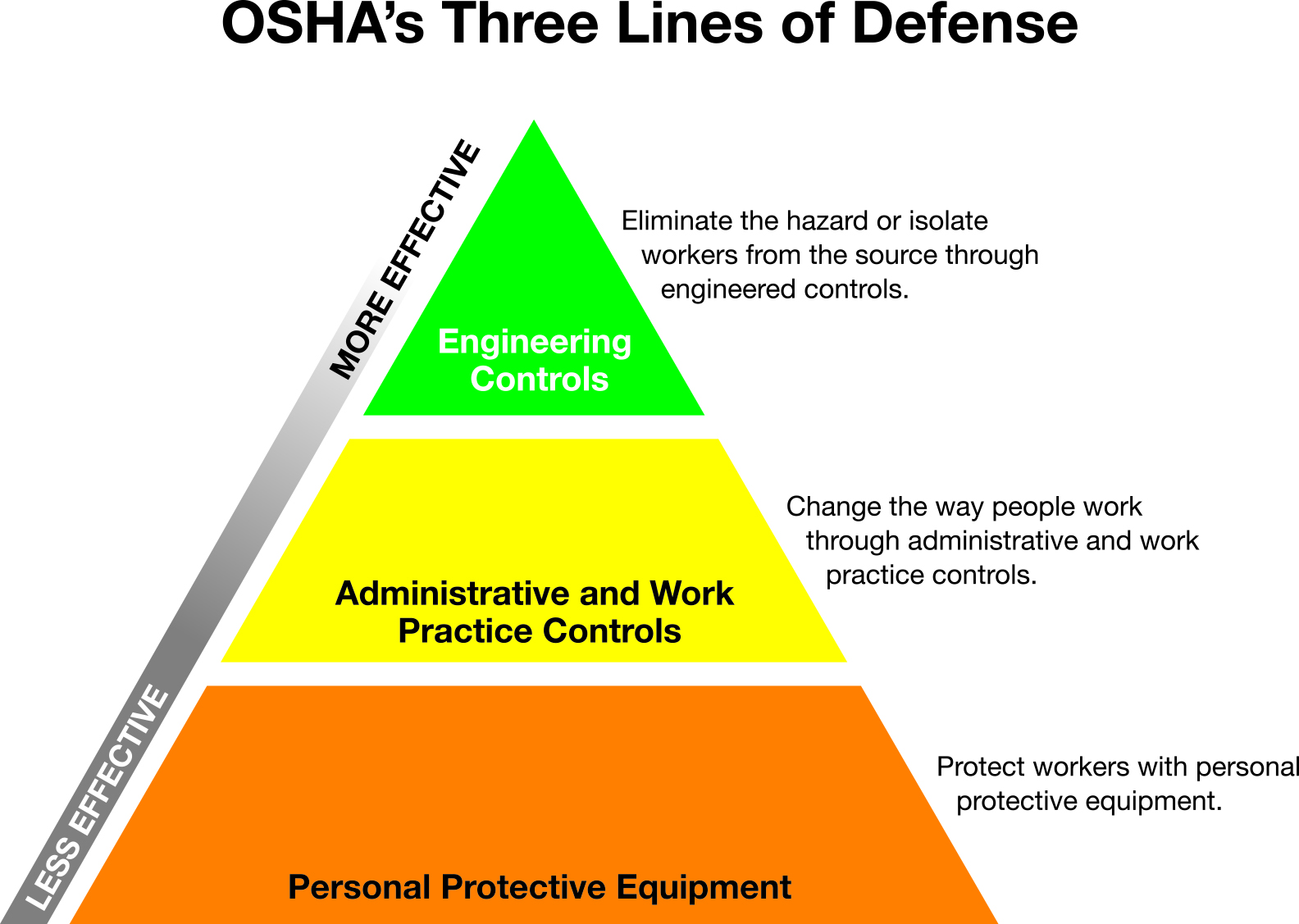

Everyone has a role in assuring a safe and healthy workplace. There are opportunities to help assess hazards and discuss accidents and near-miss incidents. Viewing these in the context of OSHA’s three lines of defense goes even further to help maintain a safe workplace.

The three lines of defense represent a way of thinking about and applying specific actions to eliminate or reduce exposures to identified hazards. They are generally depicted as a pyramid with the most effective method — engineering controls — at the pinnacle, followed by administrative/work practice controls and then PPE.

The three lines of defense are used in all workplaces, including offices, construction sites, factories, hospitals and more.

Engineering Controls

Engineering controls are the first line of defense. They are physical changes to the work area or process that minimizes a worker’s exposure to the hazard. Examples of engineering controls include installing guardrails to prevent falls, limiting exposure to hazardous chemicals via ventilation, using portable air conditioners to combat heat stress and installing noise absorption panels to dampen high noise levels.

Administrative or Work Practice Controls

The second line of defense — administrative or work practice controls — involves changes in work procedures, schedules and training that reduce the duration, frequency and severity of exposure to identified hazards. The entire operation – from management and human resources to supervisors, general staff, and line workers —has a role in developing administrative or work practice controls.

PPE

PPE is considered the last line of defense. It is equipment that is worn to minimize exposure to a variety of hazards, including but not limited to chemical, electrical, biological and mechanical. OSHA says employers must provide PPE if engineering and administrative/work practice controls are neither feasible nor sufficient to protect workers.

The three lines of defense are process-based and connect with the overall workplace safety culture. Everyone should have a say and be able to provide input into reducing unsafe conditions. It can be difficult to remove hazards completely, but the three lines of defense connect with each other, helping instill a safer work environment.

Overall, ensuring the safety of workers is a team effort — one that includes management, supervisors and line workers and OSHA’s three lines of defense.

The information contained in this article is intended for general information purposes only and is based on information available as of the initial date of publication. No representation is made that the information or references are complete or remain current. This article is not a substitute for review of current applicable government regulations, industry standards, or other standards specific to your business and/or activities and should not be construed as legal advice or opinion. Readers with specific questions should refer to the applicable standards or consult with an attorney.